Loading ...

Loading ...

Loading ...

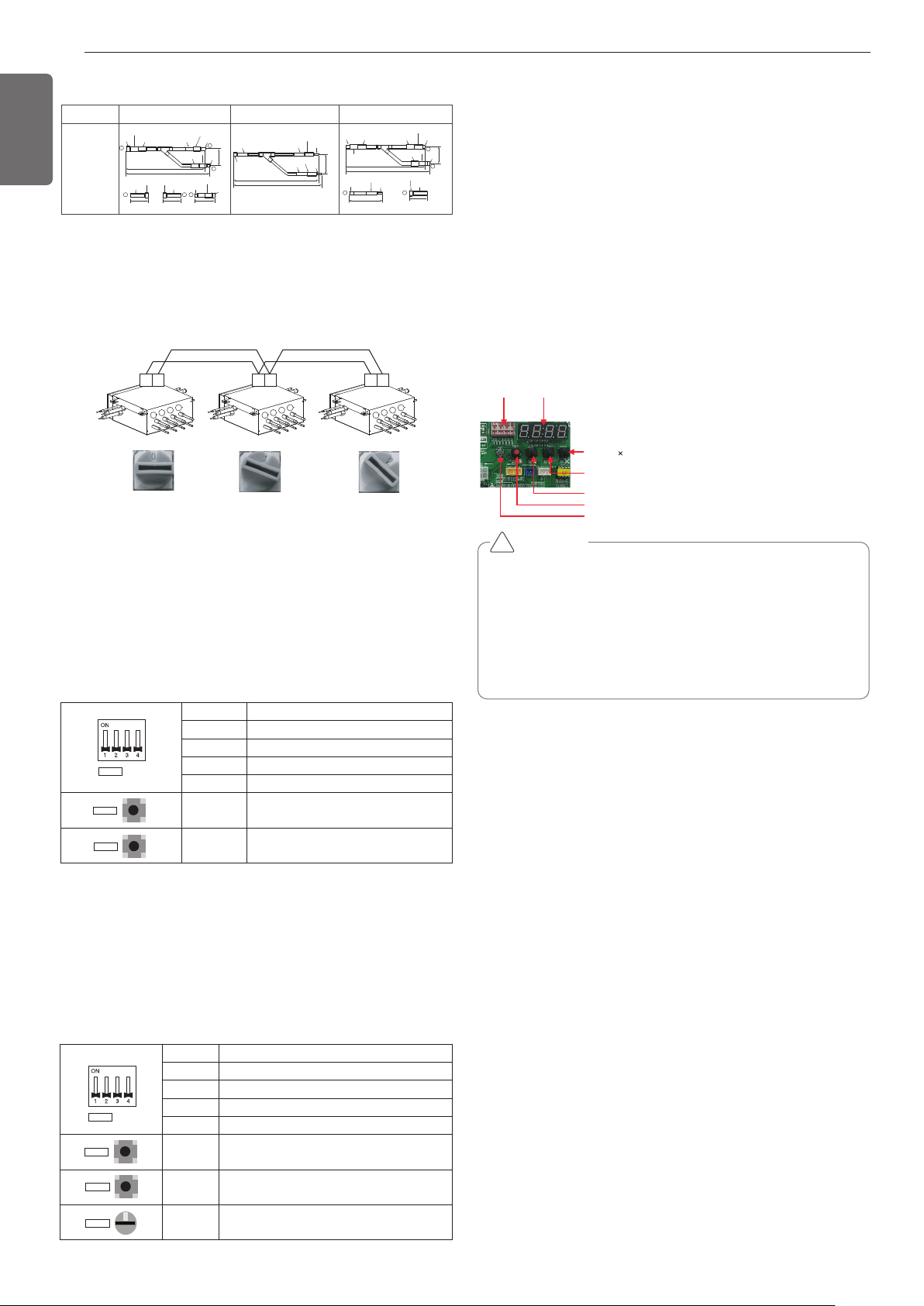

Automatic Addressing

The address of indoor units would be set by Automatic Addressing

- Wait for 3 minutes after supplying power.

(Master and Slave outside unit s, indoor units)

- Press RED button of the outside unit s for 5 seconds. (SW01C)

- A “88” is indicated on 7-segment LED of the outside unit PCB.

- For completing addressing, 2~7 minutes are required depending on

numbers of connected indoor units

-

Numbers of connected indoor units whose addressing is completed are

indicated for 30 seconds on 7-segment LED of the outside unit PCB

- Numbers of connected HR units whose addressing is completed are in-

dicated for 10 seconds on 7-segment LED of the outside unit PCB

- After completing addressing, address of each indoor unit is indicated

on the wired remote control display window. (CH01, CH02,

CH03, ……, CH06 : Indicated as numbers of connected indoor units)

[MAIN PCB]

DIP-SWITCH 7 - Segment

SW01C ( : confirm)

SW02C (ඔ : backward)

SW03C (ඖ : forward)

SW04C (

: cancel)

SW01D (reset)

CAUTION

• In replacement of the indoor unit PCB, always perform Automatic

addressing setting again (At that time, please check about using

Independent power module to any indoor unit.)

• If power supply is not applied to the indoor unit, operation error

occur.

• Automatic Addressing is only possible on the master Unit.

• Automatic Addressing has to be performed after 3 minutes to im-

prove communication.

!

Automatic pipe detection

1. Turn No.1 of SW02M of HR unit PCB off.

2. Confirm that the setting of No.2, 3 of SW02M corresponds with the

number of indoor units.

3. Reset the power of HR unit PCB

4. Master unit PCB DIP switch on : No.5

5. Select the mode using ‘▶’, ‘◀’ Button : “Idu” Push the ‘●’ button

6. Select the “Id 5” function using ‘▶’, ‘◀’ Button :“Ath” or “”Atc”

Push the ‘●’ button.

Outdoor temperature is over 15°C(59°F) : “Atc” Using (If it fail, use

“Ath”)

Outdoor temperature is below 15°C(59°F) : “Ath” Using (If it fail,

use “Atc”)

7. Select the mode using ‘▶’, ‘◀’ Button : “Idu” Push the ‘●’ button

8. Select the “Id 6” function using ‘▶’, ‘◀’ Button :“StA” Push the

‘●’ button

9. Operated after 88 is displayed on 7-SEG of the outside unit main

PCB.

10. Pipe detection proceed.

11. 5~30 minutes are required depending on the number of the indoor

units and outdoor temperature.

12. The number of the indoor units installed is displayed on 7-SEG of

the outside unit main PCB for about 1 minute

- For a HR unit, the number of the indoor units connected to each

HR unit is displayed.

- '200' is displayed in case of auto pipe detection error, and auto de-

tection is completed after '88' is disappeared.

* Auto pipe detection function : the function that sets connection re-

lationship automatically between the indoor unit and HR unit.

32

ENGLISH

ARBLB03321

Models

413(16-1/4)

390(15-11/32)

I.D19.05(3/4)

I.D19.05(3/4)

I.D19.05(3/4)

I.D15.88(5/8)

I.D12.7(1/2)

I.D12.7(1/2)

I.D12.7(1/2)

I.D12.7(1/2)

I.D12.7(1/2)

I.D12.7(1/2)

I.D12.7

(1/2)

74

(2-29/32)

70(2-3/4)

70(2-3/4)

I.D15.88(5/8)

I.D15.88(5/8)

I.D25.4(1)

I.D25.4(1)

I.D25.4(1)

O.D25.4(1)

80(3-5/32)

110(4-11/32) 110(4-11/32)

332(13-1/16)

321(12-5/8)

83

(3-9/32)

1

2

3

3

I.D19.05(3/4)

I.D19.05(3/4)

O.D19.05(3/4)

O.D19.05(3/4)

2

3 2

3

1 2

O.D15.88(5/8)

444(17-15/32)

421(16-9/16)

96

(3-25/32)

I.D15.88

(5/8)

I.D22.2(7/8)

I.D22.2(7/8)

I.D22.2(7/8)

I.D22.2(7/8)

I.D22.2(7/8)

I.D22.2(7/8)

O.D15.88(5/8)

I.D6.35(1/4)

I.D6.35(1/4)

I.D28.58(1-1/8)

I.D19.05(3/4)

I.D9.52(3/8)

I.D9.52(3/8)

I.D9.52(3/8)

I.D9.52(3/8)

Low Pressure Gas Pipe High Pressure Gas PipeLiquid pipe

Y branch pipe

[Unit : mm(inch)]

SW05M (Rotary S/W for addressing HR unit)

Must be set to '0' when installing only one HR unit.

When installing multiple HR units, address the HR units with sequen-

tially increasing numbers starting from '0'.

Ex) Installation of 3 HR units

1

2

3

4

1

2

3

4

1

2

3

4

AB AB AB

S/W No. Setup

No.1 Manual addressing of valve #1

No.2 Manual addressing of valve #2

No.3 Manual addressing of valve #3

No.4 Manual addressing of valve #4

SW03M

Increase in the digit of 10 of valve

address

SW04M

Increase in the last digit of valve ad-

dress

SW01M

SW03M

SW04M

2. Zoning setting

- Set the address of the valve of the HR unit to the central control

address of the connected indoor unit.

- SW01M : selection of the valve to address

SW03M : increase in the digit of 10 of valve address

SW04M : increase in the last digit of valve address

SW05M :Rotary S/W

- Prerequisite for manual valve addressing : central control address

of each indoor unit must be preset

differently at its wired remote control.

S/W No. Setup

No.1 Manual addressing of valve #1

No.2 Manual addressing of valve #2

No.3 Manual addressing of valve #3

No.4 Manual addressing of valve #4

SW03M

Increase in the digit of 10 of valve ad-

dress

SW04M Increase in the last digit of valve address

SW05M Manual addressing of zoning indoor units

SW01M

SW03M

SW04M

SW05M

0

SW01M/SW03M/SW04M (Dip S/W and tact S/W for

manual valve addressing)

1. Normal setting (Non-Zoning setting)

- Set the address of the valve of the HR unit to the central control

address of the connected indoor unit.

- SW01M: selection of the valve to address

SW03M: increase in the digit of 10 of valve address

SW04M: increase in the last digit of valve address

- Prerequisite for manual valve addressing : central control address

of each indoor unit must be preset differently at its wired remote

control.

Loading ...

Loading ...

Loading ...