Loading ...

Loading ...

Loading ...

23

ENGLISH

NOTE

!

If the ambient temperature differs between the time when pressure is applied

and when the pressure drop is checked, apply the following correction factor

There is a pressure change of approximately 0.01Mpa(1.5psi) for each 33.8°F

of temperature difference.

Correction= (Temp. at the time of pressurization – Temp. at the time of check)

X 0.1

For example: Temperature at the time of pressurization

3.8MPa(551psi) is 80.6°F

24 hour later: 3.73MPa(541psi), 68°F

In this case the pressure drop of 0.07MPa(10psi) is

because of temperature drop

And hence there is no leakage in pipe occurred.

CAUTION

To prevent the nitrogen from entering the refrigeration system in

the liquid state, the top of the cylinder must be at higher position

than the bottom when you pressurize the system.

Usually the cylinder is used in a vertical standing position.

!

WARNING

Use a vacuum pump or Inert(nitrogen) gas when doing leakage

test or air purge. Do not compress air or Oxygen and do not use

Flammable gases. Otherwise, it may cause fire or explosion.

- There is the risk of death, injury, fire or explosion.

!

Vacuum

Vacuum drying should be made from the service port provided on the outdoor

unit’s service valve to the vacuum pump commonly used for liquid pipe, gas pipe

and high/low pressure common pipe. (Make Vacuum from liquid pipe, gas pipe and

high/low pressure common pipe with the service valve closed.)

* Never perform air purging using refrigerant.

• Vacuum drying: Use a vacuum pump that can evacuate to -100.7kPa (-

14.6psi, 5 Torr, -755mmHg).

- Evacuate the system from the liquid and gas pipes with a vacuum pump

for over 2 hrs and bring the system to -100.7kPa(-14.6psi). After maintain-

ing system under that condition for over 1 hr, confirm the vacuum gauge

rises. The system may contain moisture or leak.

- Following should be executed if there is a possibility of moisture remain-

ing inside the pipe.

(Rainwater may enter the pipe during work in the rainy season or over a

long period of time)

After evacuating the system for 2 hrs, give pressure to the system to

0.05MPa(7.3psi) (vacuum break) with nitrogen gas and then evacuate it

again with the vacuum pump for 1hr to -100.7kPa(-14.6psi)(vacuum dry-

ing). If the system cannot be evacuated to -100.7kPa(-14.6psi) within 2

hrs, repeat the steps of vacuum break and its drying. Finally, check if the

vacuum gauge does not rise or not, after maintaining the system in vac-

uum for 1 hr.

Indoor unit

Liquid side

Gas side

High Pressure

Gas pipe

High Pressure

Gas pipe

Liquide pipe

Liquide pipe

Low Pressure

Gas pipe

Low Pressure

Gas pipe

HR unit

Scale

Use a graviometer. (One that can

measure down to 0.1kg). If you are

unable to prepare such a

high-precision gravimeter you may use

a charge cylinder.

Slave 1 outside unit Master outside unit

Close

Close

Close

Vacuum

pump

Vacuum

pump

Close

Close

Close

NOTE

!

Always add an appropriate amount of refrigerant. (For the refrigerant addi-

tional charge)

Too much or too little refrigerant will cause trouble.

To use the Vacuum Mode

(If the Vacuum mode is set, all valves of Indoor units and Outdoor units will

be opened.)

WARNING

When installing and moving the air conditioner to another site,

recharge after perfect evacuation.

- If a different refrigerant or air is mixed with the original refriger-

ant, the refrigerant cycle may malfunction and the unit may be

damaged.

!

This function is used for creating vacuum in the system after compres-

sor replacement, ODU parts replacement or IDU addition/replacement.

Vacuum mode setting method

Vacuum mode off method

CAUTION

ODU operation stops during vacuum mode. Compressor can't

operate.

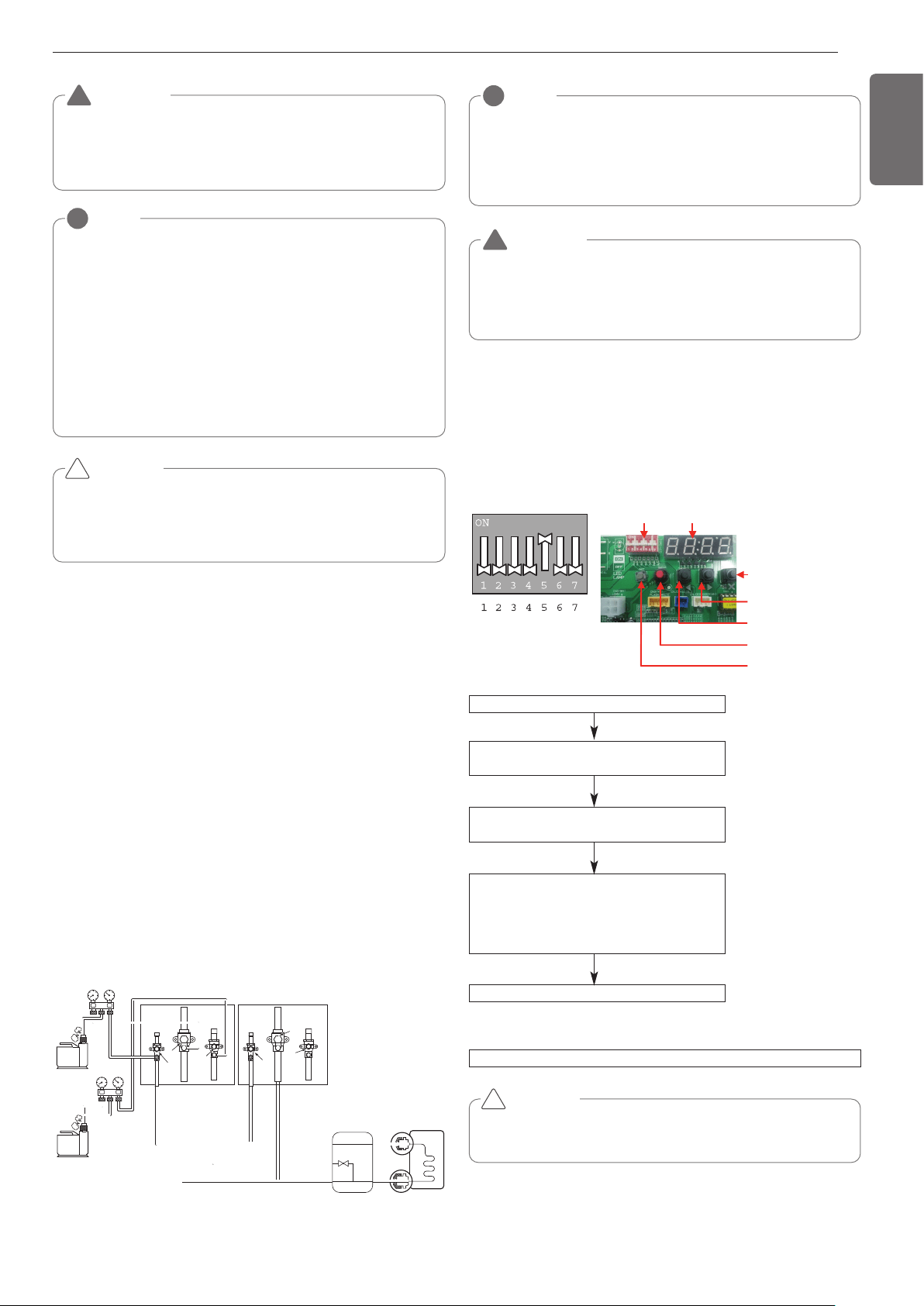

Master unit PCB DIP switch on : No.5

Vacuum mode

Select the mode using ‘▶’, ‘◀’ Button :

“SVC” Push the ‘●’ button

Select the Function using ‘▶’, ‘◀’ Button :

“Se1” Push the ‘●’ button

Start the vacuum mode : “VACC”

ODU V/V open

ODU EEV open

IDU EEV open

Dip switch off and push the reset button on Master unit PCB

!

Vacuum Mode

DIP SWITCH 7-Segment

SW01C ( : confirm)

SW02C ( : backward

: forward)

SW04C

( X : cancel)

SW01D (reset)

SW03C (

ȭ

ȯ

Ɨ

Loading ...

Loading ...

Loading ...