Loading ...

Loading ...

Loading ...

Westinghouse Portable Power | 25

3. The reset button should pop out and there will

be no power from the outlets. If the reset button

does not pop out, the GFCI outlet is not working

correctly and must be repaired before the generator

can be operated.

4. Press the reset button to restore power to the

outlet.

CLEANING THE GENERATOR

It is important to inspect and clean the generator before

every use.

Clean All Engine Air Inlet and Outlet Ports – Make

sure all engine air inlet and outlet ports are clean of any

dirt and debris to ensure the engine does not run hot.

Clean All Engine Cooling Fins – Use a damp rag and

a brush to loosen and remove all dirt on or around the

engine’s cooling ns.

Clean All Alternator Cooling Air Inlets and Exhaust

Ports – Make sure the cooling air inlets and exhaust

ports of the alternator are free of any debris and ob-

structions. Use a vacuum cleaner to remove dirt and

debris stuck in the cooling air inlets and exhaust ports.

General Cleaning of the Generator – Use a damp rag

to clean all remaining surfaces.

TESTING GFCI OUTLETS

1. Start the generator and allow it to warm up.

2. Press the test button on the GFCI outlet.

MAINTENANCE

Test Button

Reset Button

CHECKING AND ADJUSTING VALVE LASH

CAUTION

Checking and adjusting valve lash

must be done when the engine is cold.

1. Remove the rocker arm cover and carefully remove

the gasket. If the gasket is torn or damaged, it must

be replaced.

2. Remove the spark plug so the engine can be

rotated more easily.

3. Rotate the engine to top dead center (TDC) of the

compression stroke. Looking through the spark

plug hole, the piston should be at the top.

4. Both the rocker arms should be loose at TDC on

the compression stroke. If they are not, rotate the

engine 360°.

5. Insert a feeler gauge between the rocker arm and

the push rod and check for clearance (see Figure

23). See Table 2 for valve lash specications

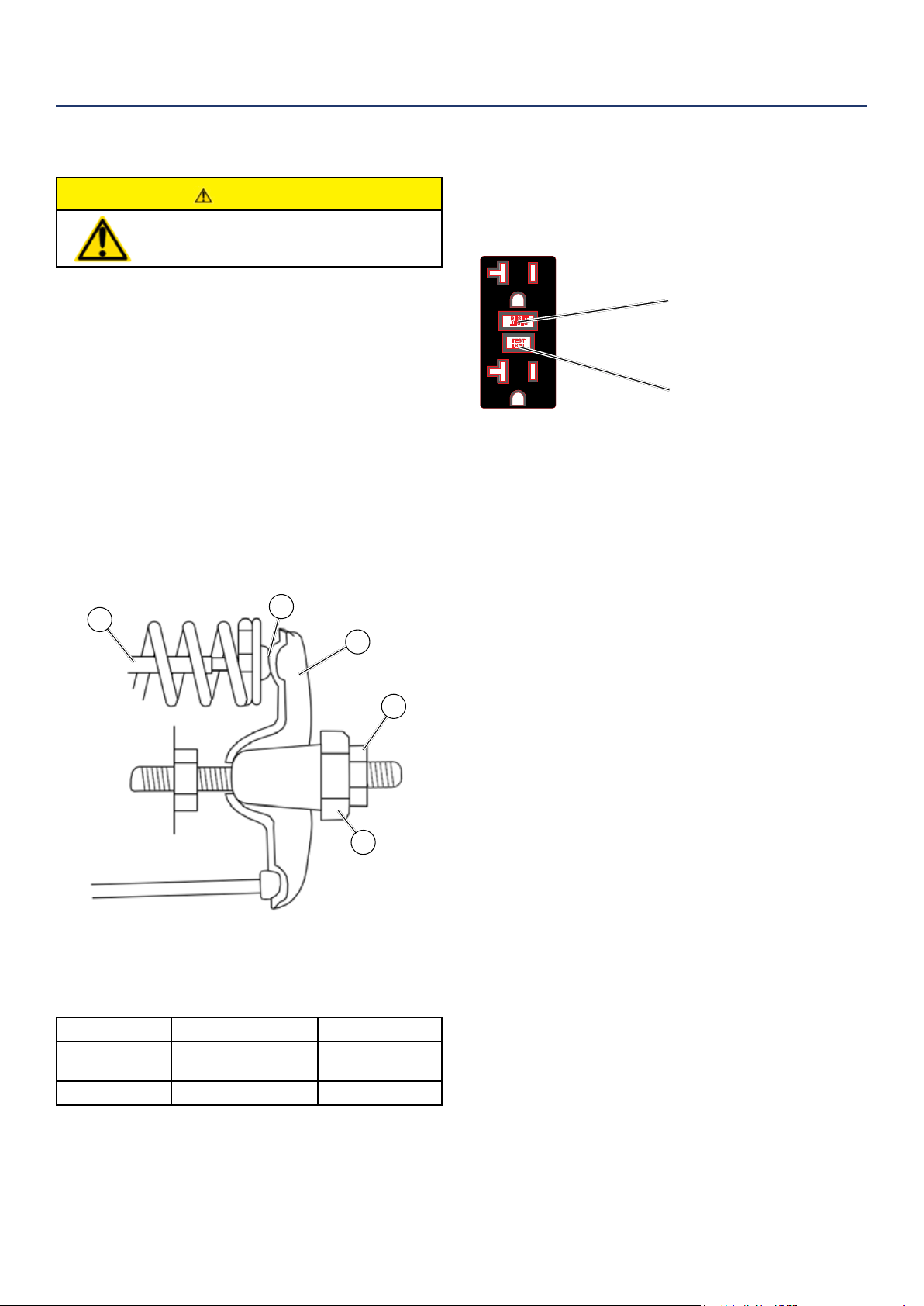

Figure 23

(1) Push Rod, (2) Feeler Gauge Area

(3) Rocker Arm, (4) Jam Nut, (5) Adjusting Nut

(Table 2) Standard Valve Lash

Intake Valve Exhaust Valve

Valve Lash

0.0035 ± 0.0043 in

(0.09 ± 0.11 mm)

0.0043 ± 0.0051 in

(0.11 ± 0.13 mm)

Bolt Torque

8-12N.m 8-12N.m

6. If an adjustment is required, hold the adjusting nut

and loosen the jam nut.

1

2

3

4

5

Loading ...

Loading ...

Loading ...