Loading ...

Loading ...

Loading ...

KBF / KBF-UL + KMF (E6) 04/2020 page 83/163

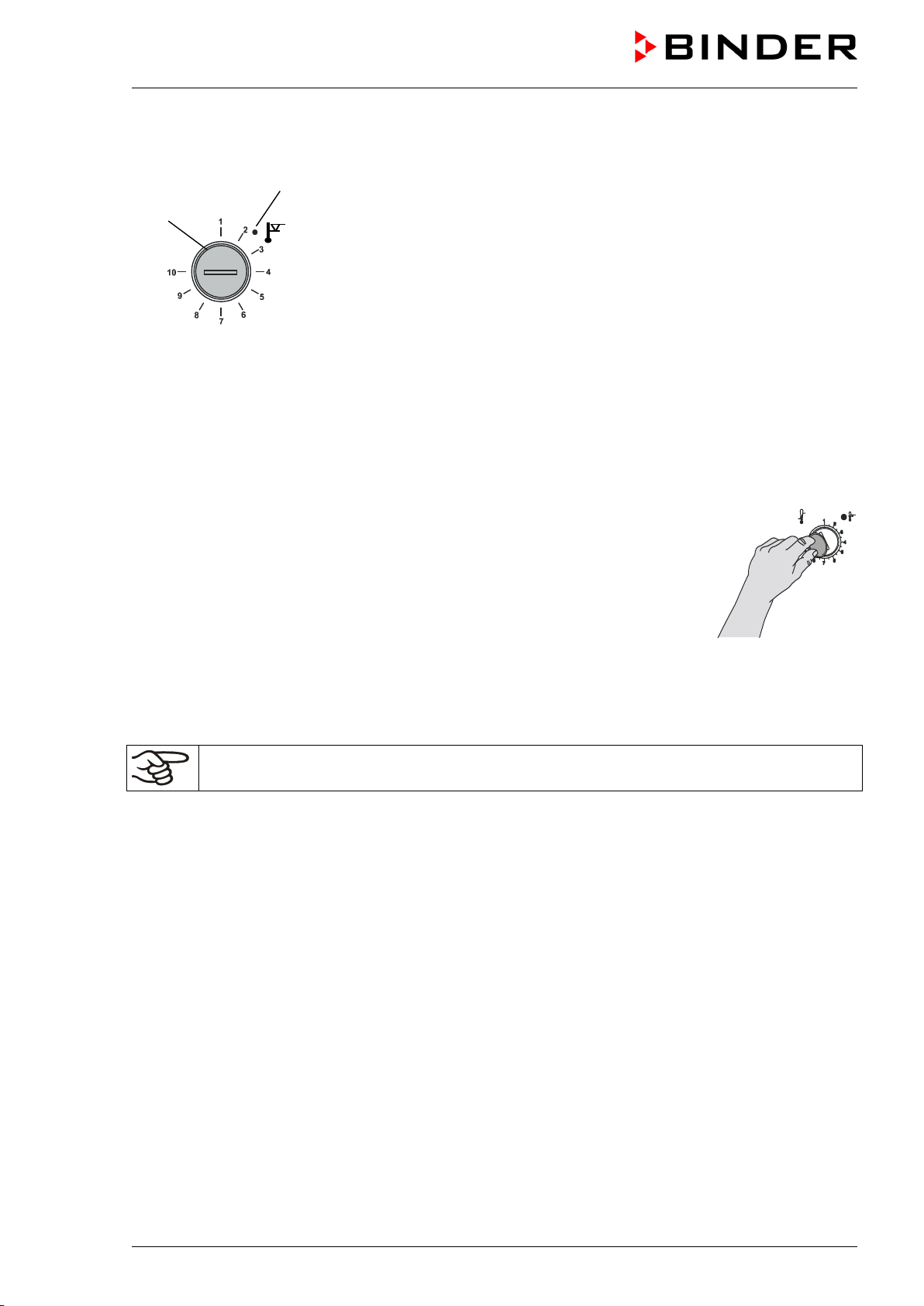

12.3.1 Temperature safety device class 3.1

If you turn the control knob (8) to its end-stop (position 10), the safety device

class 3.1 protects the appliance. If you set the temperature a little above the

set-point, it protects the loading material.

If the safety device class 3.1 has taken over control, identifiable by the red

alarm lamp (8a) lighting up, the message “Temp. safety device” on the con-

troller will be displayed and the buzzer will sound, then proceed as follows:

• Reset the buzzer by pressing the Reset alarm icon on the controller

• Disconnect the chamber from the power supply

• Have an expert examine and rectify the cause of the fault.

• Start up the chamber again

Setting:

To check the response temperature of the safety device class 3.1, turn on the chamber and set the de-

sired set point at the temperature controller.

The sections of the scale from 1 to 10 correspond to the temperature range from 0 °C / 32 °F to 120 °C /

248 °F and serve as a setting aid.

• Turn the control knob (8) of the safety device using a coin to its end-stop (posi-

tion 10) (chamber protection).

• When the set point is reached, turn back the control knob (8) until its trip point

(turn it counter-clockwise).

• The trip point is identifiable by the red alarm lamp (8a), the message “Temp.

safety device” on the controller

display, and the buzzer sounds. Reset the

buzzer with the Reset alarm icon on the controller.

• The optimum setting for the safety device is obtained by turning the control

knob clockwise by approximately two scale divisions, which shuts off the red

alarm lamp (8a).

Figure 17

: Setting

safety device class

3.1

Check the setting regularly and adjust it following changes of the set-point or charge.

Function check:

Check the temperature safety device class 3.1 at appropriate intervals for its functionality. It is recom-

mended that the authorized operating personnel should perform such a check, e.g., before starting a

longer work procedure.

(8a)

(8)

Loading ...

Loading ...

Loading ...