Loading ...

Loading ...

Loading ...

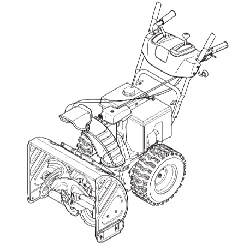

Lamp Wiring Harness (If equipped)

The post on the cable tie attaching the lamp wiring harness to

the lower handle should be plugged into the hole in the lower

handle. Pull the slack portion of the wiring harness through the

cable tie to prevent interference with the recoil starter handle.

See Fig. 3-16.

Figure 3-16

Tires

Pneumatic (Air-Pressurized) Tires

The tires are over-inflated for shipping purposes. Check the tire

pressure before operating the snow thrower. Refer to the tire side

wall for tire manufacturer’s recommended psi and deflate (or

inflate) the tires as necessary.

WARNING: Under any circumstance do not exceed

manufacturer’s recommended psi. Equal tire

pressure should be maintained at all times. Excessive

pressure when seating beads may cause tire/rim

assembly to burst with force sufficient to cause

serious injury. Refer to sidewall of tire for

recommended pressure.

NOTE: Equal tire pressure is to be maintained at all times for

performance purposes.

Non-Pneumatic (Airless) Tires

Some units are equipped with non-pneumatic tires. Therefore,

these airless tires are considered maintenance free with regards

to air pressure.

Adjustments

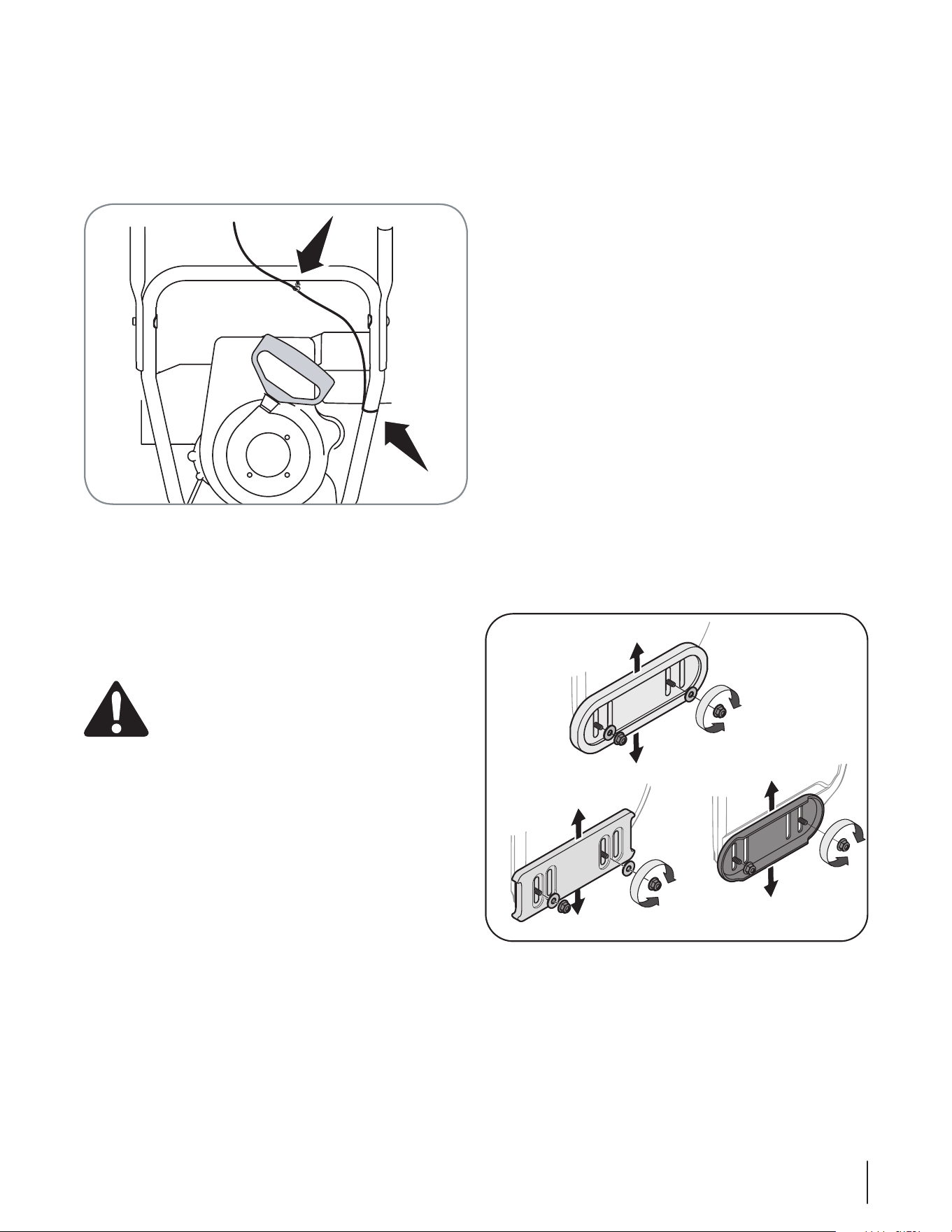

Skid Shoes

The snow thrower skid shoes are adjusted at the factory for

shipping purposes. Adjust them downward, if desired, prior to

operating the snow thrower.

CAUTION: It is not recommended that you operate this snow

thrower on gravel as it can easily pick up and throw loose gravel,

causing personal injury or damage to the snow thrower and

surrounding property.

• For close snow removal on a smooth surface, raise skid

shoes higher on the auger housing.

• Use a middle or lower position when the area to be cleared

is uneven, such as a gravel driveway.

NOTE: If you choose to operate the snow thrower on a gravel

surface, keep the skid shoes in position for maximum clearance

between the ground and the shave plate.

NOTE: Some models are equipped with reversible skid shoes

and may be turned over to increase their lifespan.

To adjust the skid shoes:

1. Loosen the four hex nuts (two on each side), washers (if

equipped) and carriage bolts. Move skid shoes to desired

position. See Fig. 3-17.

2. Make certain the entire bottom surface of skid shoe is

against the ground to avoid uneven wear on the skid

shoes.

3. Retighten nuts, washers (if quipped) and bolts securely.

Figure 3-17

11Section 3 — ASSembly & Set-Up

Loading ...

Loading ...

Loading ...