Loading ...

Loading ...

Loading ...

5

A

B

c

b

a

defgh

i

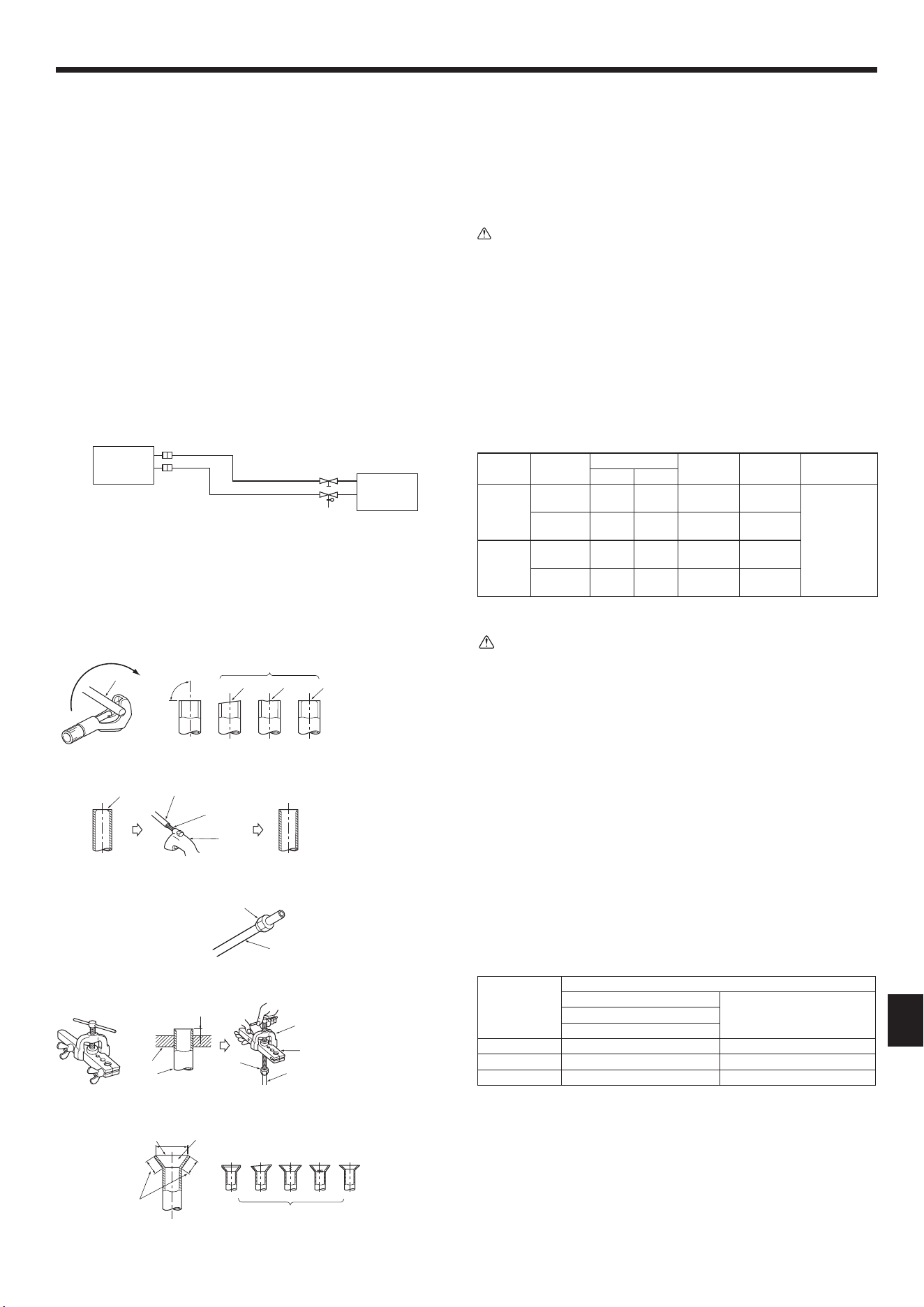

5. Refrigerantpipingwork

A Indoor unit

B Outdoor unit

ø6.35(1/4")

SLZ-KF09,KF12:ø9.52(3/8")

SLZ-KF15,KF18:ø12.7(1/2")

Fig.5-1

a Copper tubes

b Good

c No good

d Tilted

e Uneven

f Burred

Fig.5-2

Fig.5-3

a Burr

b Coppertube/pipe

c Spare reamer

d Pipecutter

Fig.5-4

Fig.5-5

Fig.5-6

a Flare nut

b Copper tube

a Flaring tool

b Die

c Copper tube

d Flare nut

e Yoke

B

a

d

cb

ef

90

d

c

b

a

b

a

a

b

e

b

c

d

c

A

5.1. Precautions

FordevicesthatuseR410Arefrigerant

• Usealkylbenzeneoil (small amount) as the refrigeration oil applied to the

aredsections.

• UseC1220copperphosphorusforcopperandcopperalloyseamlesspipes,

toconnecttherefrigerantpipes.Userefrigerantpipeswiththethicknesses

specied in the table below. Make sure the insides of the pipes are clean

anddonotcontainanyharmfulcontaminantssuchassulfuriccompounds,

oxidants,debris,ordust.

Warning:

Wheninstalling or relocating, or servicing the air conditioner, use only the

specied refrigerant written on outdoor unit tocharge the refrigerant lines.

Donotmixitwithanyotherrefrigerantanddonotallowairtoremaininthe

lines.

Ifairismixedwiththerefrigerant,thenitcanbethecauseofabnormalhigh

pressureintherefrigerantline,andmayresultinanexplosionandotherhaz-

ards.

Theuseofanyrefrigerantotherthanthatspeciedforthesystemwillcause

mechanicalfailureorsystemmalfunction or unit breakdown. In the worst

case,thiscouldleadtoaseriousimpedimenttosecuringproductsafety.

5.2. Refrigerantpipe(Fig.5-1)

Pipingpreparation

(1)Tablebelowshowsthespecicationsofpipescommerciallyavailable.

Model Pipe

Outside diameter

Min.wall

thickness

Insulation

thickness

Insulation

material

mm inch

SLZ-KF09

SLZ-KF12

Forliquid 6.35 1/4

0.8 mm

(1/32inch)

8 mm

(10/32inch)

Heat resist-

ing foam

plastic 0.045

specic

gravity

For gas 9.52 3/8

0.8 mm

(1/32inch)

8 mm

(10/32inch)

SLZ-KF15

SLZ-KF18

Forliquid 6.35 1/4

0.8 mm

(1/32inch)

8 mm

(10/32inch)

For gas 12.7 1/2

0.8 mm

(1/32inch)

8 mm

(10/32inch)

(2)Ensurethatthe2refrigerantpipesarewellinsulatedtopreventcondensation.

(3)Refrigerantpipebendingradiusmustbe100mm(4inch)ormore.

Caution:

Usingcarefulinsulationofspeciedthickness.Excessivethicknessprevents

storagebehindtheindoorunitandsmallerthicknesscausesdewdrippage.

5.3. Flaringwork

• Maincauseofgasleakageisdefectinaringwork.

Carryoutcorrectaringworkinthefollowingprocedure.

5.3.1. Pipecutting(Fig.5-2)

• Usingapipecuttercutthecoppertubecorrectly.

5.3.2. Burrsremoval(Fig.5-3)

• Completelyremoveallburrsfromthecutcrosssectionofpipe/tube.

• Puttheendofthecoppertube/pipetodownwarddirectionasyouremoveburrsin

ordertoavoidburrsdropinthetubing.

5.3.3. Puttingnuton(Fig.5-4)

• Removearenutsattachedtoindoorandoutdoorunit,thenputthemonpipe/tube

havingcompletedburrremoval.

(notpossibletoputthemonafteraringwork)

5.3.4. Flaringwork(Fig.5-5)

• Carryoutaringworkusingaringtoolasshownattheright.

Pipediameter

(mm,inch)

Dimension

A(mm,inch)

B

+0

-0.4

,1/64(mm,inch)

WhenthetoolforR410Aisused

Clutch type

6.35,1/4" 0to0.5,0to1/64 9.1,11/32

9.52,3/8" 0to0.5,0to1/64 13.2,17/32

12.7,1/2" 0to0.5,0to1/64 16.6,21/32

Firmlyholdcoppertubeinadieinthedimensionshowninthetableatabove.

5.3.5. Check(Fig.5-6)

• Comparethearedworkwithagureinrightsidehand.

• Ifareisnotedtobedefective,cutoffthearedsectionanddoaringworkagain.

a Smooth all around f Scratchonaredplane

b Inside is shining without any scratches g Cracked

c Evenlengthallaround h Uneven

d Too much i Badexamples

e Tilted

Loading ...

Loading ...

Loading ...