Loading ...

Loading ...

Loading ...

CUTTING AIDS AND ACCESSORIES

CUT OFF GAUGE

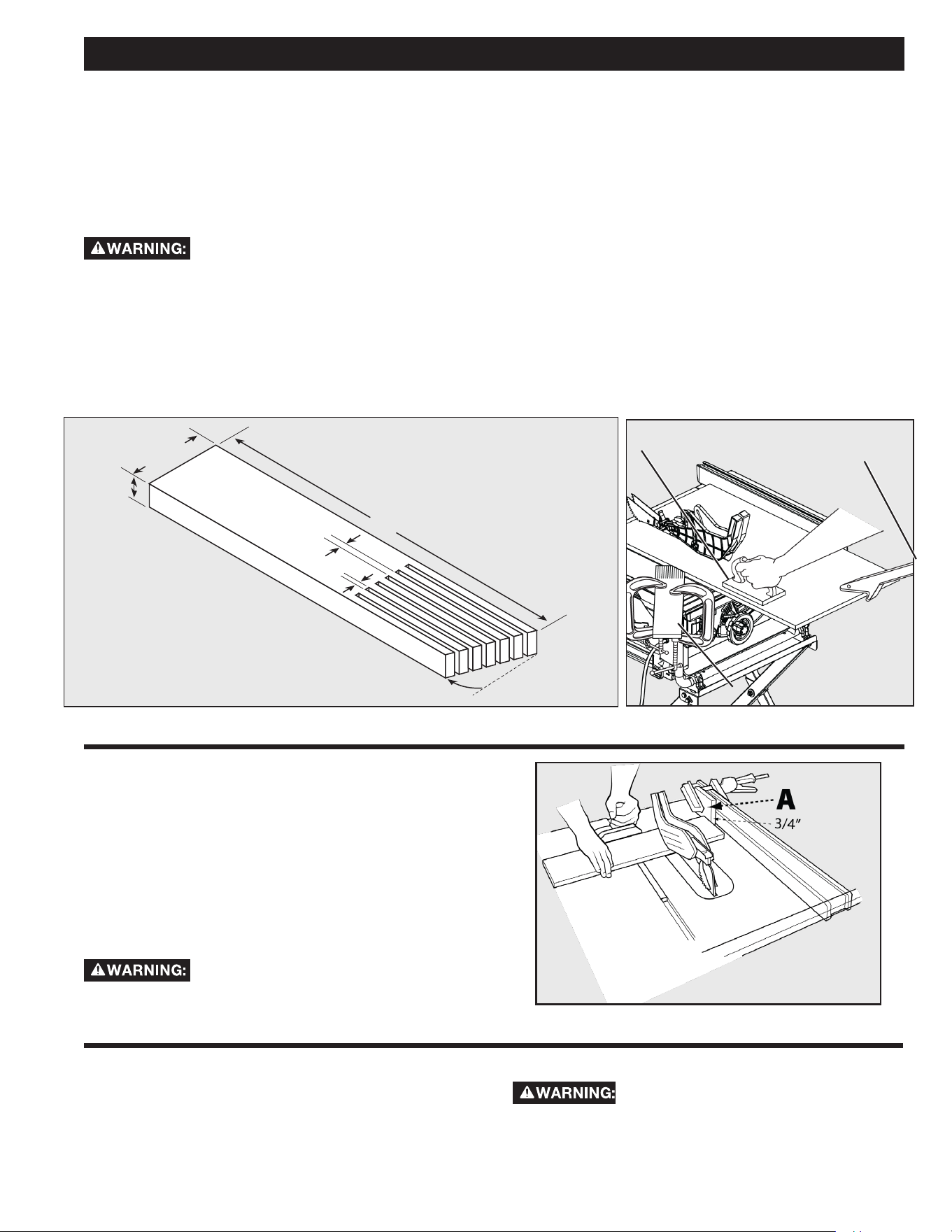

When crosscutting a number of pieces to the same length,

you can clamp a block of wood (A) (See Figure 39) to the

fence and use it as a cut-off gauge. The block (A) must be at

least 3/4-inch (19 mm) thick to prevent the cut off piece from

binding between the blade and the fence. Once the cut-off

length is determined, lock the fence and use the miter gauge

to feed the workpiece into the blade.

Always position the cut-off gauge in front of

the saw blade.

FIGURE 39

FIGURE 38 FIGURE 38A

FEATHERBOARD

1. Select a solid piece of lumber approximately 3/4-inch

thick, 2 1/2-inches wide and 12-inches long.

2. Mark the center width on one end of stock. Miter width

to 70° (see miter cut section for information on miter

cuts).

3. Set rip fence to allow approximately a 1/4-inch “nger”

to be cut in the stock.

4. Feed stock only to mark previously made at 6 inches.

5. Turn saw o and allow blade to completely stop rotating

before removing stock.

6. Reset rip fence and cut spaced rips into workpiece

to allow approximately 1/4-inch ngers and 1/8-inch

spaces between ngers.

Featherboards are used to keep the work in contact with

the fence and table (Figure 38), and help prevent kickback.

Featherboards are especially useful when ripping small

workpieces and for completing non-through cuts. The end is

angled with a series of narrow slots to give a friction hold on

the workpiece, It is locked in place on the table or fence with a

c-clamp.

To avoid binding between the workpiece and

the blade, make sure a horizontal feather board presses only

on the uncut portion of the workpiece in front of the blade.

Dimensions for making a typical featherboard are shown in

Figure 38. Make your featherboard from a straight piece of

wood that is free of knots and cracks. Clamp featherboards to

the fence and/or table so that the featherboard will hold the

workpiece against the fence or table.

FIGURE 38

JIGS

Do not attempt to create or use a jig unless

you are thoroughly familiar with table saw

safety. Do not use any jig that could result in pinching a kerf

or jamming the workpiece between the jig and the blade.

Incorrect setups may cause kickback which could result in

serious injury.

Jigs may be created with a variety of special set-ups to control

particular workpiece shapes for particular cuts. Guidance on

how to make specialized jigs can be found in woodworking and

carpentry websites and publications.

3/4 in.3/4 in.

12 in.12 in.

70˚70˚

2 1/2 in.2 1/2 in.

1/4 in.1/4 in.

1/8 in.1/8 in.

PUSH BLOCK PUSH BLOCK

FEATHER BOARD FEATHER BOARD

PUSH STICK PUSH STICK

29

Loading ...

Loading ...

Loading ...