Loading ...

Loading ...

Loading ...

OPERATION

STARTING AND STOPPING THE SAW

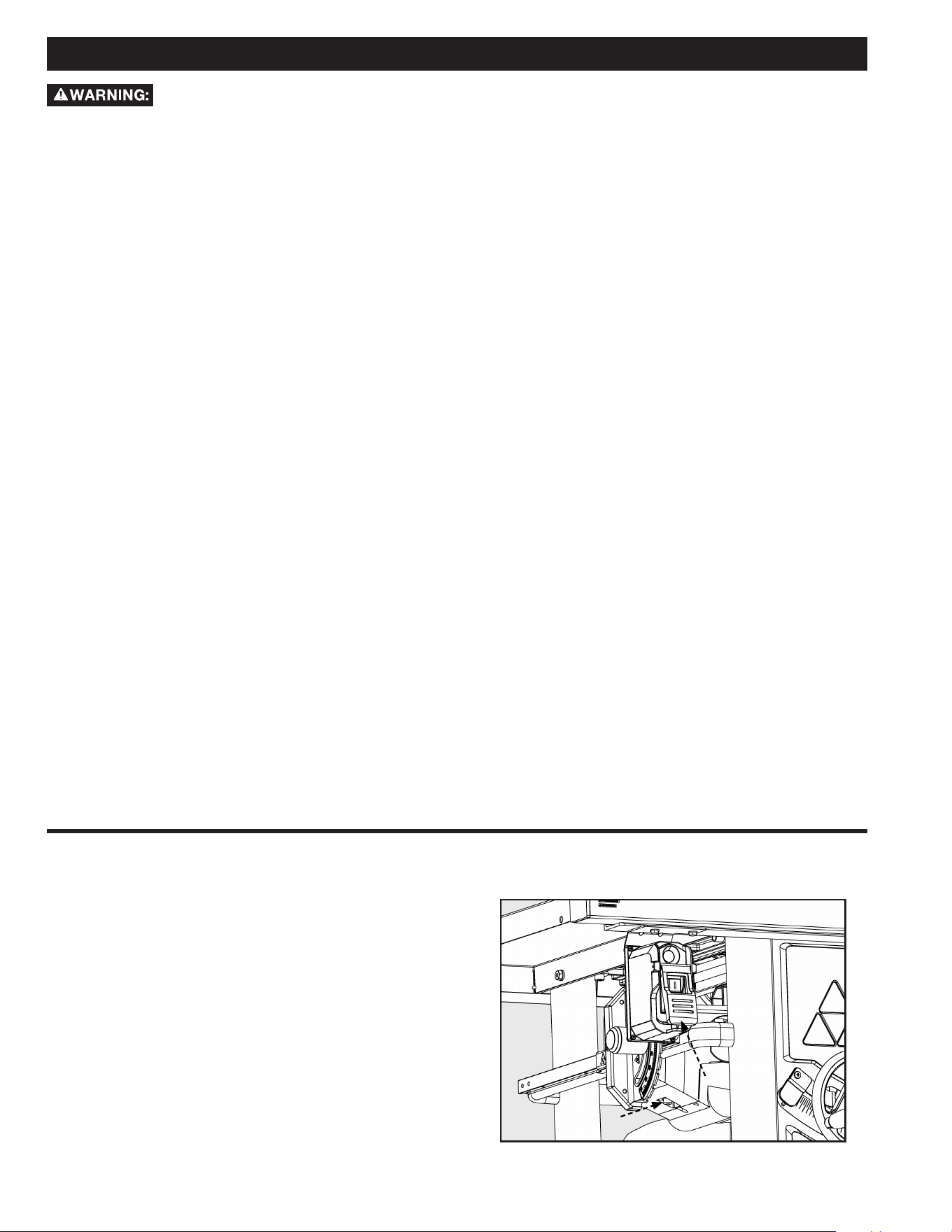

The POWER switch (Figure 27) is located underneath the front

left extension wing.

1. To turn the saw“ON”, pull the red paddle switch (A) up

and toward you.

2. To turn the saw “OFF”, push the red paddle switch in.

When not in use, the saw should be turned off and the power

switch locked out to prevent unauthorized use. To lock out

power switch, use a standard long shackle lock, with a shackle

that is at least 2 3/4 - inches (70mm) long and with shackle

posts no larger than 9/32-inch (7mm) thick.

FIGURE 27

Failure to comply with the following the warnings may result in serious personal injury.

READ ENTIRE MANUAL. In addition to reading these operating instructions, it is important to read and understand the entire

manual before operating this saw. Follow all applicable instructions regarding assembly, preparation, and adjustment prior to

making any cuts and comply with all safety rules and warnings in this section and elsewhere throughout this manual.

1. Each time you use the saw, run through the following

checklist:

• Are the power source and power connections adequate for

the saw?

• Are the saw and work area free of clutter and by-standers?

• Is the blade tight and properly aligned?

• Does the riving knife thickness match the blade?

• Are the blade and riving knife properly aligned?

• Is the operator qualied to make the cut and familiar with

all of the relevant safety rules, warnings and instructions

included in this manual?

• Is the operator and everyone in proximity to the saw

wearing appropriate eye, hearing and respiratory

equipment?

• Are the bevel angle and height adjustment knobs locked in

the proper position?

• Is the blade set at the proper height?

• If ripping, is the rip fence parallel to the blade and securely

locked in position?

• If crosscutting, is the miter gauge knob tight?

• If making through cuts with a standard blade, are the

blade guard riving knife and anti-kickback pawls properly

attached and properly functioning with both guards

contacting the table surface?

• Is there proper clearance and support for the workpiece as

it leaves the blade?

• Are any cutting aids needed? If so, are they in place, or

within reach for proper use?

2. The use of attachments and accessories not

recommended by Delta Power Equipment Corporation

may result in injury.

3. Replace or sharpen the anti-kickback ngers when the

points become dull.

AVOID KICKBACK

A kickback can occur when the workpiece pinches the blade, or

binds between the saw blade and the rip fence or other fixed

object. This can cause the workpiece to rise from the table

and/or be thrown back toward the operator. See instructions

for reducing the risk of kickback on page 7 of this manual.

IF KICKBACK OCCURS, turn the saw “OFF” and verify

proper alignment of the blade, riving knife and miter gauge or

rip fence, and the proper functioning of the riving knife, anti-

kickback assembly and blade guard assembly before resuming

work.

4. Make sure saw is stable and cutting can be

accomplished without tipping the saw. Do not attempt

to cut large workpieces without securing saw to a stable

surface. To properly secure the saw, see instructions in

section entitled Securing Saw to the Floor on page 15 of

this manual.

5. Never use the fence and miter gauge together without

using a cuto block as previously described.

6. The proper throat plate must be in place at all times.

7. If your saw makes an unfamiliar noise or if it vibrates

excessively, cease operating immediately until the

source has been located and the problem corrected.

8. Never perform freehand cutting, plunge cutting,

re-sawing or cove cutting.

B

A

22 23

Loading ...

Loading ...

Loading ...