Loading ...

Loading ...

Loading ...

8

9

OPERATION

WARNING

To reduce the risk of injury, always

wear proper eye protection marked

to comply with ANSI Z87.1.

When working in dusty situations, wear appro-

priate respiratory protection or use an OSHA

compliant dust extraction solution.

Keep hands and body out of the path of the saw

blade. Contact with blade will result in serious

injury. Check guarding system to make sure it is

functioning correctly. Do not operate saw without

guards in place. Do not perform any operation

freehand. Never reach around saw blade. Turn

off tool and wait for saw blade to stop before

moving workpiece or changing settings. Tighten

all adjustments prior to use.

Cut Line Indicator

The cut-line indicator shines down the blade, casting

a shadow where the blade will meet the workpiece.

No calibration/adjustments will be needed as the

shadow will always be true to the blade location.

Use the cut-line indicator switch to turn on the light

before making a cut. The light will go off automatically

about 9 seconds after use.

WARNING

To reduce the risk of injury, do not

rely on the brake as a safety fea-

ture. Always wait until the blade

stops completely before allowing anything near

the blade.

To reduce the risk of injury, make sure all adjust-

ments are securely locked before making a cut.

Starting and Stopping the Tool

Always hold the trigger handle fi rmly because the

starting and stopping action of the motor may cause

the handle to move up or down slightly. WARNING!

Always press down miter lock lever and tighten all

adjustments prior to use. WARNING! Ensure hands

are out of the No Hands Zone.

1. To start the motor, push down the trigger lock and

pull the trigger.

2. To stop the motor, release the trigger. The elec-

tric brake will stop the blade in about 4 seconds.

WARNING! The brake is not a substitute for the

guards and could fail; always wait for the blade to

stop completely before removing the blade from

the workpiece. If the brake fails to stop the blade or

misses frequently, return the tool to a MILWAUKEE

service facility for repair.

Making a Chop Cut

Cut workpieces with chop cuts whenever possible.

Only use sliding cuts (cross cuts) when necessary.

1. Select the desired angles and adjust the fences to

ensure fence hand holds are positioned to keep

hands out of the No Hand Zone.

2. Place the workpiece on the turntable and line up

the cut.

3. Insert battery pack.

4. Support the workpiece using any of the methods

described in "Support the Workpiece Properly".

5. WARNING! Keep hands out of the No Hands

Zone at all times during use. Contact with blade

will result in serious injury.

6. Start the motor. Wait a few seconds for the blade to

reach full speed. Then gently lower the saw head

into the workpiece all the way through the cut.

WARNING! Do not allow the blade to contact the

workpiece while tool is ramping up.

7. Always allow the saw to do the work. Forcing the

tool may stall or overheat the motor.

8. After the cut is complete, release the trigger and

wait for the blade to stop completely. Raise the

saw head and remove the workpiece. WARNING!

If small cut-off pieces get caught in the guard area,

remove battery pack before clearing.

Making a Sliding Cut (Cross Cut)

Wider workpieces can be cut using the sliding

mechanism. Always use chop cut whenever possible.

4

2

3

1

1. Make sure that the slide rail transport lock is loose,

and the saw head moves freely back and forth.

2. Select the desired angles and adjust the fences to

ensure fence hand holds are positioned to keep

hands out of the No Hand Zone.

3. Place the workpiece on the turntable and line up

the cut.

4. Insert battery pack.

5. Support the workpiece using any of the methods

described in "Support the Workpiece Properly".

6. WARNING! Keep hands out of the No Hands

Zone at all times during use. Contact with blade

will result in serious injury.

7. Raise saw head and pull it out OVER the work-

piece WITHOUT cutting.

8. Start the motor. Wait a few seconds for the blade

to reach full speed. WARNING! Do not allow

the blade to contact the workpiece while tool is

ramping up.

9. Press down on saw head.

10. Push saw through the cut. WARNING! Return

saw head to the full rear position after each

crosscut operation.

11. After the cut is complete, release the trigger and

wait for the blade to stop completely. Raise the

saw head and remove the workpiece. WARNING!

If small cut-off pieces get caught in the guard

area, remove battery pack before clearing.

APPLICATIONS

WARNING

Do not cut stone, brick, concrete,

magnesium, or ferrous metals

(iron, steel, stainless steel, or alloys of these

metals) with this saw.

Do not use abrasive wheels with this saw.

Dust created by cutting these materials and/or

using abrasive cut-off wheels can jam the blade

guard and possibly cause personal injury.

Recommended Materials and Applications

The following materials can be cut with the compound

sliding miter saw. There are many types of saw

blades available. Always use the proper blade for the

particular material and application. Use only 7-1/4"

sliding miter saw blades rated at least 5000 RPM.

• Wood - solid wood, plywood, particle board, MDF

(medium density fi berboard), HDF (high density

fi berboard), melamine laminated particle board,

formica laminates, hardboard (masonite).

• Plastics - PVC, CPVC, ABS, solid surfacing materi-

als (such as Corian

®

), and other plastic materials.

When cutting plastic, avoid overheating the blade

and blade teeth to prevent melting the workpiece.

• Nonferrous Metals - aluminum, brass, copper, and

other non-ferrous materials.

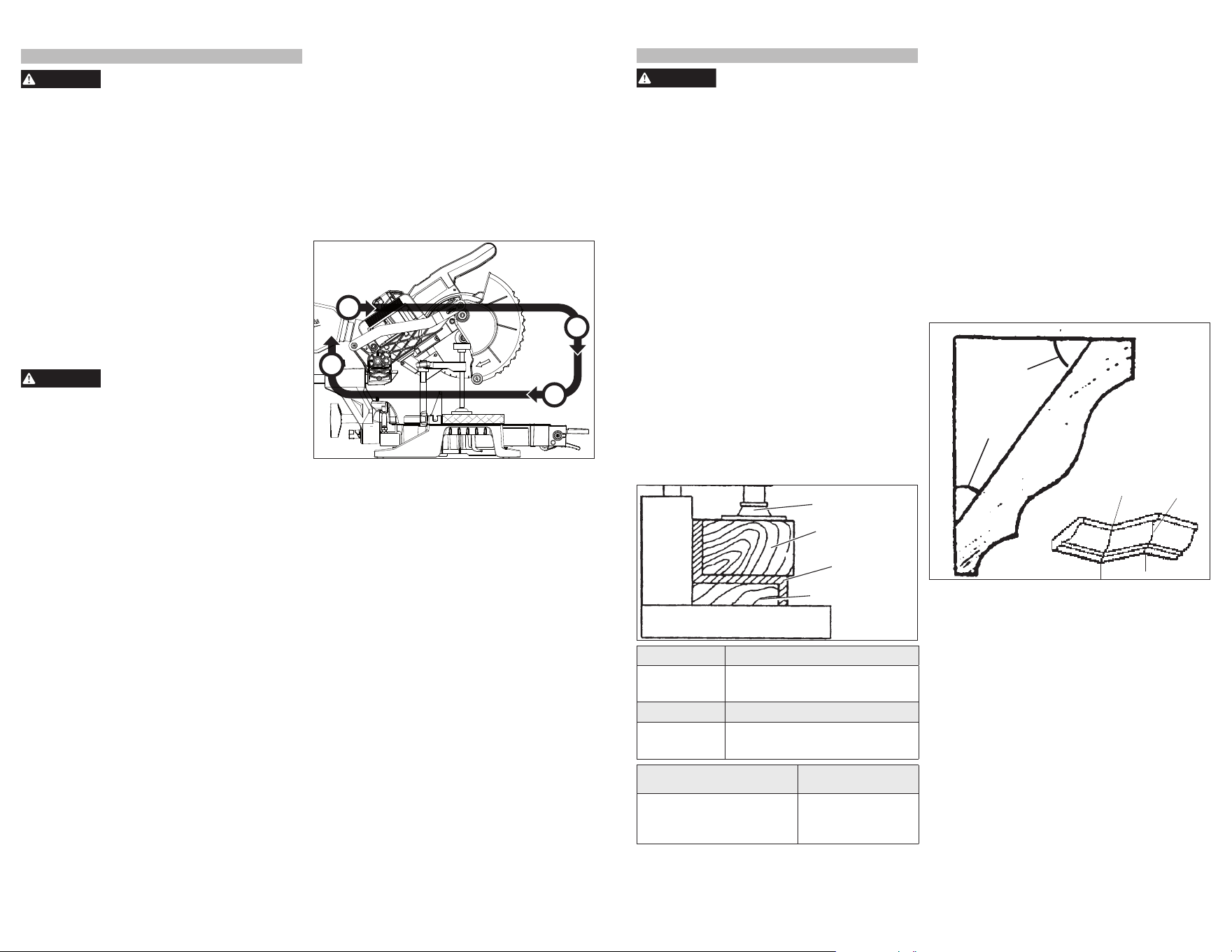

Cutting Non-Square Materials

Cutting Round (Cylindrical) Materials

"V" shaped blocks can be used to support round

materials like closet rod and plastic pipe.

Aluminum Sash and Other

Channel Type and Materials

Aluminum sash material can be supported with blocks

to prevent it from deforming while it is being cut.

Clamp

Fence

Table

Wood support

block

Aluminum

material

Wood support

block

Miter Range Miter Detents (Stops)

0° to 45° Left

0° to 45° Right

0°, 15°, 22.5°, 31.62°, 45° Left

0°, 15°, 22.5°, 31.62°, 45° Right

Bevel Range Bevel Detents (Stops)

0° to 48° Left

0° to 48° Right

0°, 45° Left

0°, 45° Right

Base Molding

Capacity

Nested Crown

Capacity

3-1/2" at 0°

3-1/2" at 45° Left

3-1/2" at 45° Right

3-5/8"

Two Methods for Cutting Crown Molding

The angles created on a piece of crown molding that

fi ts fl at against the ceiling and wall will, when added

together, equal 90° (A + B = 90°).The most common

crown molding angles are :

52

°

/38

°

: A 52° angle against the ceiling (A) and a 38°

angle against the wall (B). The miter saw has spe-

cial miter settings at 31.6° left and right and a bevel

setting at 33.9° to use when cutting 52°/ 38° crown

molding fl at on the miter saw table. These settings

are identifi ed with a diamond mark.

45

°

/45

°

: A 45° angle against the ceiling (A) and a 45°

angle against the wall (B). The miter saw has special

miter settings at 35.3° left and right and a bevel set-

ting at 30° to use when cutting 45°/ 45° crown fl at

on the miter saw table. These settings are identifi ed

with a black circle.

NOTE: Even though all of these angles are standard,

rooms are very rarely constructed so the corners

are exactly 90°. You will need to “fi ne tune” these

settings and make necessary adjustments to the

cutting angles.

Ceiling

Wall

Angle B

Angle A

Inside

corner

Outside

corner

Cutting Crown Molding Flat on the

Miter Saw Table

The advantage of cutting crown molding fl at on the

table is that it is easier to secure the molding at the

correct cutting position. Also larger pieces of crown

molding may be cut lying fl at on the miter saw table.

1. Set the bevel and miter angles using the Crown

Molding Miter Angles chart. Tighten the miter lock

lever and the bevel adjustment lever.

2. Using the Positioning section below, correctly

positions the molding.

NOTE: Always make a test cut on scrap material

to confi rm all angles are correct.

3. Make the cut according to "Making a Chop Cut".

Cutting Crown Molding Angled Against

the Fence (Nested – in position)

Bevel settings are not required when cutting crown

molding against the fence. Small changes in the miter

angle can be made without aff ecting the bevel angle.

When using this method the saw can be quickly and

easily adjusted for corners that are not 90° (square).

Loading ...

Loading ...

Loading ...