Loading ...

Loading ...

Loading ...

-20-

Model W1666/W1685 (For Machines Mfd. Since 2/15)

SETUP

Plastic duct generates

static electrical build-up

that can cause fire or

shock. Properly ground

all plastic duct to

reduce this risk.

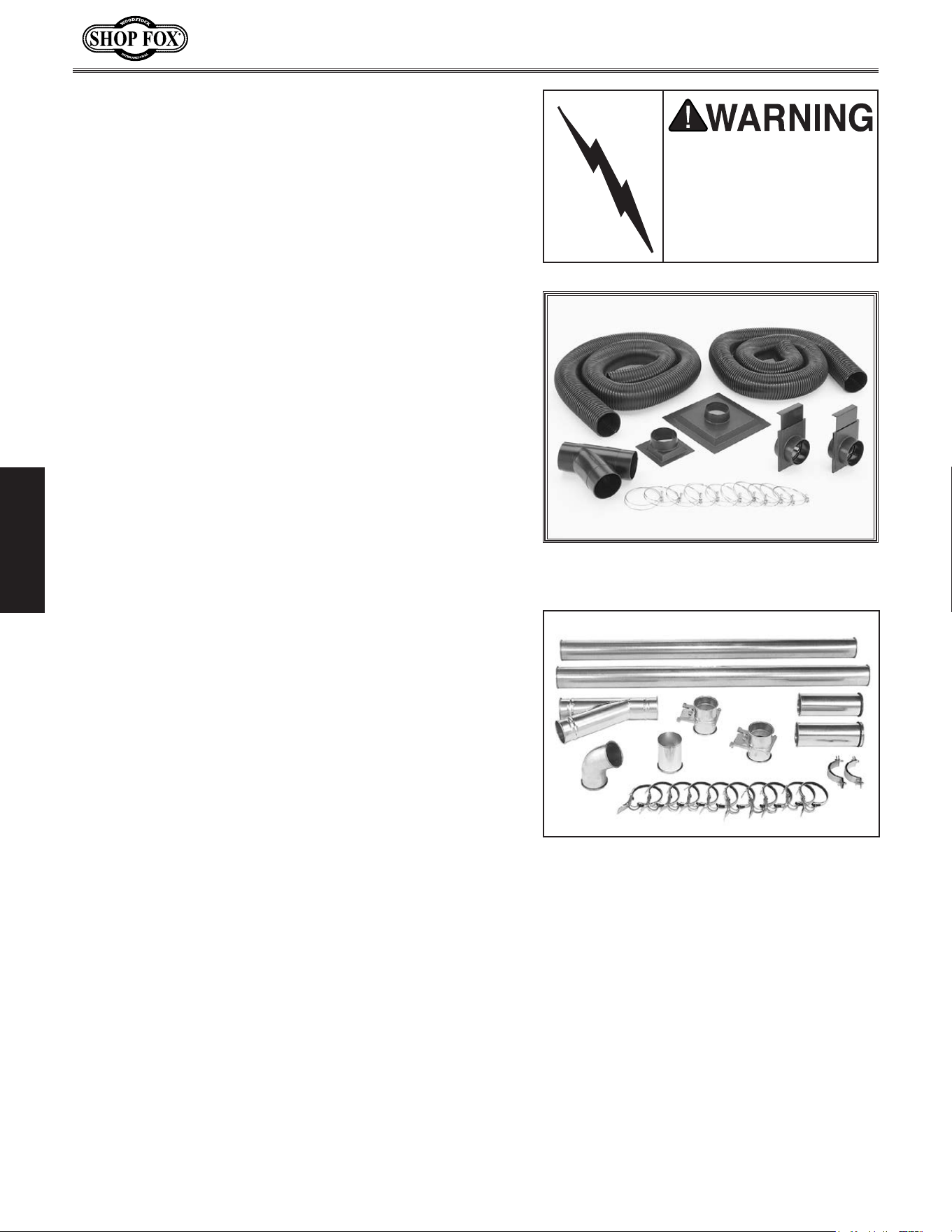

Plastic.Duct

The popularity of plastic duct is due to the fact that it

is an economical and readily available product. It is also

simple to assemble and easily sealed against air loss. The

primary disadvantage of plastic duct for dust collection is

the inherent danger of static electrical build-up.

Metal.Duct

Advantages of metal duct is its conductivity, efficiency,

and that it does not contribute to static electrical charge

build-up. However, static charges are still produced when

dust particles strike other dust particles as they move

through the duct. Since metal duct is a conductor, it can

be grounded quite easily to dissipate any static electrical

charges.

There are a number of options when it comes to metal

duct, but metal duct that is specially manufactured

for dust collection is the best choice. When selecting

your metal duct, choose high quality metal duct with

smooth welded internal seams that will minimize airflow

resistance. This type of duct usually connects to other

ducts or elbows with a simple, self-sealing clamp, is very

quick and easy to assemble, and can be readily dismantled

and re-installed. This is especially important if you ever

need to change things around in your shop or add more

tools.

Avoid inferior metal duct that requires you to cut it to

length and snap it together. This type of duct is time

consuming to install because it requires you to seal all

the seams with silicone and screw the components on

the ends with sheet metal screws. Another disadvantage

is the rough internal seams and crimped ends that

unavoidably increase static pressure loss.

Figure.20. Examples of plastic duct

components (Model W1055).

Figure.21. Examples of metal duct

components.

Loading ...

Loading ...

Loading ...