Loading ...

Loading ...

Loading ...

TROUBLESHOOTING

MAINTENANCE

To reduce the risk of injury, turn unit off and disconnect it from power source before cleaning or servicing, before installing and

removing accessories, before adjusting and when making repairs. An accidental start-up can cause injury.

KEEP MACHINE CLEAN

Periodically blow out all air passages with dry compressed

air. All plastic parts should be cleaned with a soft damp cloth.

NEVER use solvents to clean plastic parts. They could possibly

dissolve or otherwise damage the material.

Wear certified safety equipment for eye, hearing and

respiratory protection while using compressed air.

For best performance use a shop vacuum or blower to keep

saw blade area, the dust collection system, the guarding

system and rails free of saw dust and other debris.

LUBRICATION & RUST PROTECTION

Apply hardwood ooring paste wax to the machine table

occasionally or use a commercially available protective

product designed for this purpose. Follow the manufacturer’s

instructions for use and safety.

To clean cast iron tables of rust, you will need the following

materials: a medium sized scouring pad, a can of spray

lubricant and a can of degreaser. Apply the spray lubricant and

polish the table surface with the scouring pad. Degrease the

table, then apply the protective product as described above.

MAINTENANCE REMINDERS

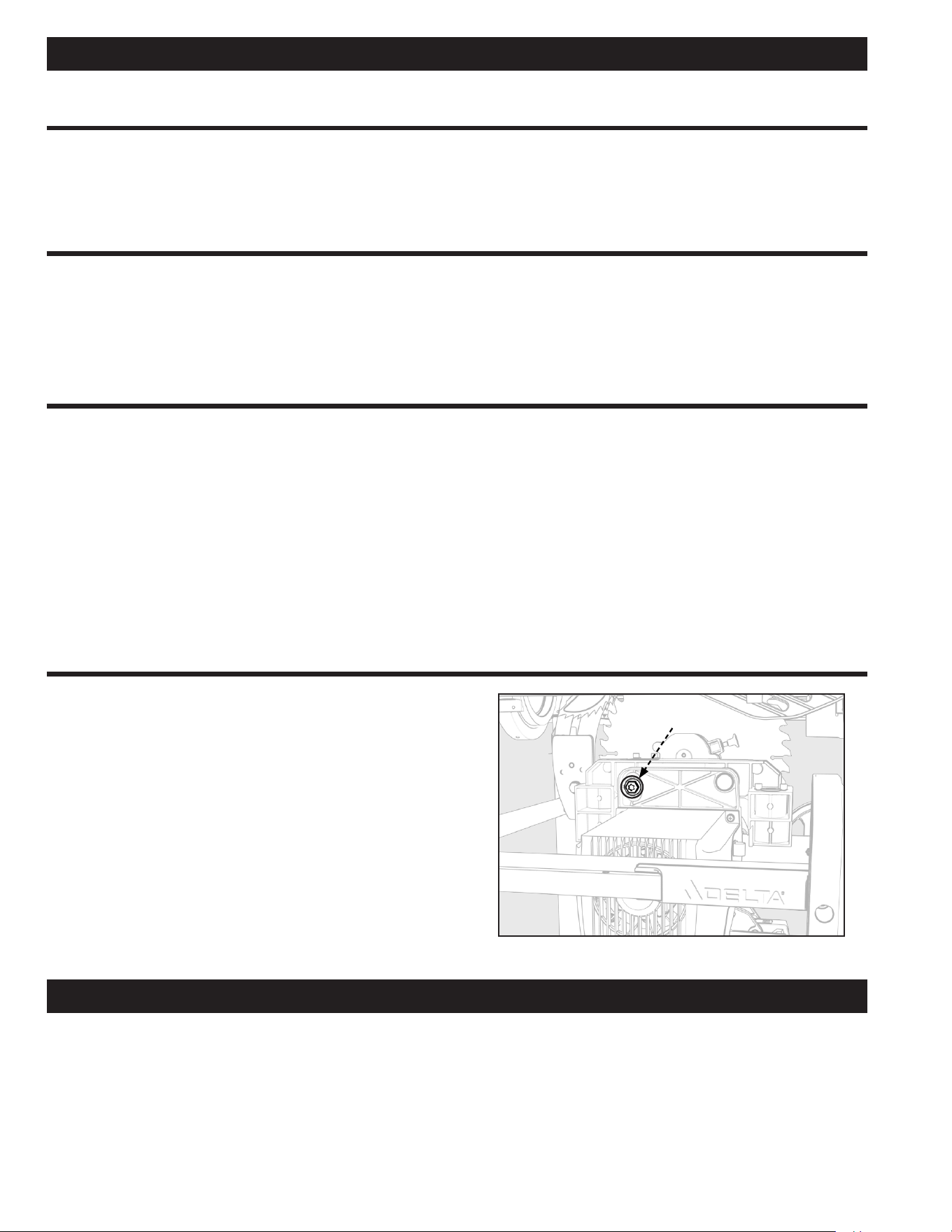

ADJUSTING BELT TENSION

WORM GEARS: Keep the worm gears free of dust and debris

buildup. Blow out area regularly with compressed air. Use a

lithium-based multipurpose grease as needed on these gears.

Wear certified safety equipment for eye, hearing and

respiratory protection while using compressed air.

1. Lower the blade height to its lowest position.

2. Loosen the torx screw (A) that is used to mount the

motor housing. This should be loosened enough to feel

the motor weight providing tension to the belt.

3. Tighten the torx screw (A) to secure the motor in place.

CLEAN SAWDUST BUILDUP OUT OF CABINET PERIODICALLY:

NOTE: Debris can also be removed from the saw from below

the throat plate, inside the dust port.

Specific areas which require regular maintenance include:

RIVING KNIFE CLAMP PLATE: Keep this area free of dust and

debris buildup. Blow out area regularly with compressed air.

NOTE: If the riving knife clamp can’t move freely, have

the saw serviced by authorized DELTA

®

Power Equipment

Corporation service center personnel.

NOTE: If table saw with belt tension adjusted function, only

the technician can do the adjustment.

For assistance with your machine, visit our website at www.DeltaMachinery.com for a list of service centers or call Delta Power

Equipment Customer Care at 1-800-223-7278.

FAILURE TO START

If your machine fails to start, check to make sure the prongs on the cord plug are making good contact in the receptacle, and check

reset button on power switch housing. Also, check for blown fuses or open circuit breakers in your power line.

FIGURE 46

A

32 33

Loading ...

Loading ...