Loading ...

Loading ...

Loading ...

OPERATION

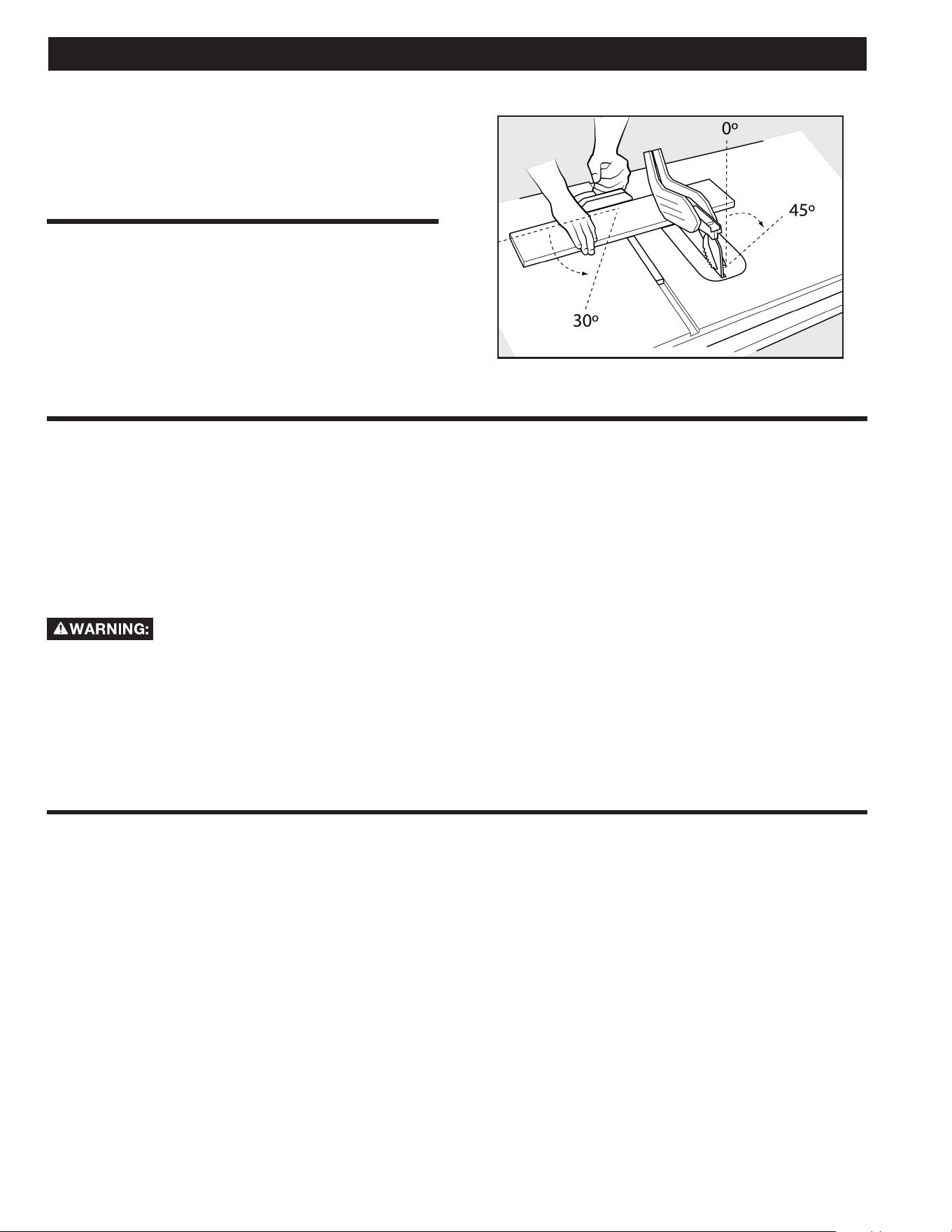

COMPOUND MITER CUTS

This is a combination of bevel crosscutting and mitering.

Refer to Figure 32 and follow the instructions for both bevel

crosscutting and mitering. Remember to use the right miter

slot for all bevel cuts.

LARGE PANEL CUTS

Place workpiece supports at the same height as the saw table

behind saw to support the cut workpiece, and alongside (s) of

saw, as needed. Depending on shape of panel, use rip fence or

miter gauge to control workpiece. If a workpiece is too large to

use either a rip fence or a miter gauge, it is too large for this

saw.

FIGURE 32

NON-THROUGH CUTS

The use of a non-through cut is essential to cutting grooves,

rabbets and dados. Non-through cuts can be made using a

standard blade having a diameter of 10 inches or less. Non-

through cuts are the only type of cuts that should be made

without the blade guard assembly installed. Make sure the

blade guard assembly is reinstalled upon completion of this

type of cut.

• Never feed wood with hands when making any non-

through cuts such as rabbets. Always use miter gauge,

push blocks or push sticks, and featherboards where

appropriate.

• Read the appropriate section which describes the type of

cut in addition to this section on non-through or dado cuts.

For example, if your non-through cut is a straight cross

cut, read and understand the section on straight cross cuts

before proceeding.

• Once all dado and non-through cuts are completed, unplug

saw and reinstall riving knife or return it to raised position.

Install anti-kickback pawls and blade guard.

• Carefully follow the instructions accompanying any

specialized blades and molding cutters for proper

installation, set up and operation.

• When making non-through cuts, follow all applicable

warnings and instructions listed below in addition to those

listed above for the relevant through cut.

• When making a non-through cut, blade is covered by

workpiece during most of cut. Be alert to exposed blade at

start and nish of every cut.

MAKING A NON-THROUGH CUT

1. Unplug saw.

2. Unlock release lever.

3. Adjust bevel angle to 0°.

4. Lock release lever.

5. Remove blade guard and anti-kickback pawls.

6. Place riving knife in “lowered” position. (see RIVING

KNIFE HEIGHT SETTINGS Section on page 20)

7. Set blade to correct depth for workpiece.

8. Depending on shape and size of wood, use either rip

fence or miter gauge.

9. Plug saw into power source and turn saw on.

90º

10. Let blade build up to full speed before moving

workpiece into blade.

11. Always use push blocks, push sticks, and/or

featherboards when making non-through cuts to reduce

the risk of serious injury.

12. When cut is made, turn saw o. Wait for blade to come

to a complete stop before removing workpiece.

13. When cut is complete re-adjust riving knife to position

as detailed on page 20.

• Once all non-through cuts are completed, unplug saw and

reinstall riving knife in raised position. Install anti-kickback

pawls and blade guard.

26 27

Loading ...

Loading ...

Loading ...