Loading ...

Loading ...

Loading ...

CUTTING AIDS AND ACCESSORIES

AUXILIARY RIP FENCE FACING

Use an auxiliary rip fence facing when needed for special cuts,

such as ripping material that is thin enough to slide under the

rip fence provided with your saw, or when a taller rip fence

is necessary to complete your cut. To add an auxiliary wood

facing to one or both sides of the rip fence, select a piece of

wood with smooth surfaces, Attach the wood to the rip fence

with two clamps. (see Figure 35) For most work, 3/4-inch

(19mm) or 1-inch (25mm) stock is suitable.

FIGURE 35

AUXILIARY MITER GAUGE FACING

An auxiliary miter gauge facing is used to increase the surface

area of the miter gauge face.

The use of miter gauge with auxiliary facing is the same as

original miter gauge (without auxiliary facing). See Page 21 for

the use of miter gauge.

If desired, you can fit the miter gauge with an auxiliary wood

facing that should be at least 1-inch (25mm) higher than the

maximum depth of cut, and at least as wide as the miter

gauge.

This auxiliary wood facing can be fastened to the front of the

miter gauge by using two wood screws through the holes (A)

provided in the miter gauge body and into the wood facing.

See Figure 36. Make sure the screws are long enough to

secure the facing, but do not extend all the way through the

wood.

FIGURE 36

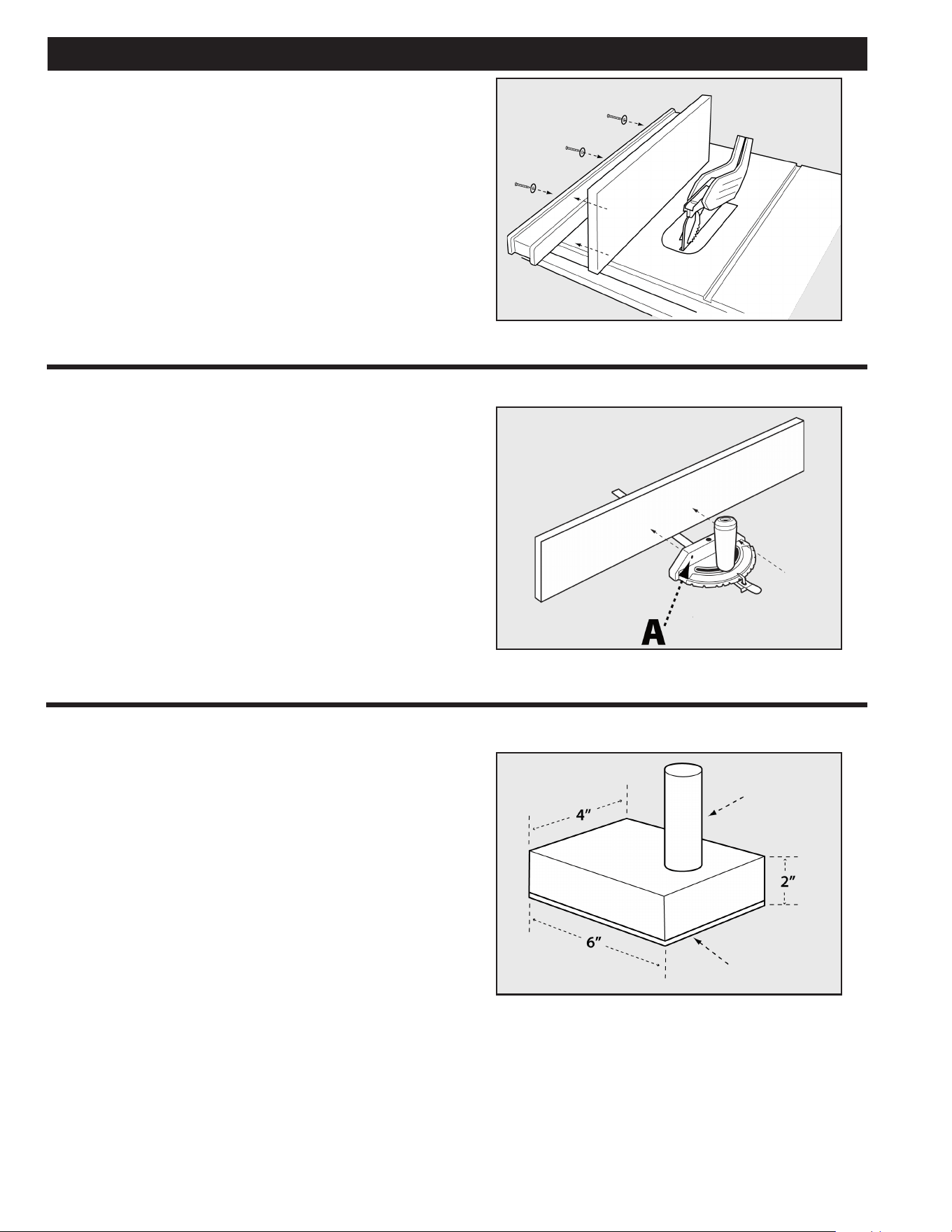

PUSH BLOCK

1. Select a piece of wood about 4-inches wide, 6-inches

long and 1- to 2-inches thick (a cuto from a 2 by 4

makes a good blank for a push block).

2. Drill a hole in the block and glue in a dowel to use as

a handle (you can angle the hole to provide a more

comfortable grip on the handle).

3. Glue a piece of rough or soft material such as

sandpaper or rubber to the bottom of the block to grip

the workpiece (old mouse pads work well). See Figure

37.

FIGURE 37

Wooden

dowel

Sandpaper or

old

mouse pad

material

Push blocks are blocks used to securely hold down the

workpiece against the table. They include some gripping

surface or handle to hold the block. Any screws running

through the underside of the block to fasten the handle should

be recessed in order to avoid contact with the workpiece.

Grooving and rabbeting

Clamping a featherboard in front of the blade can increase

safety during non-through cuts, like grooving and rabbeting,

and through cuts. Use a featherboard to guide the workpiece

against the table and fence when making non-through

cuts such as rabbeting. A featherboard helps to control the

kickback.

28 29

Loading ...

Loading ...

Loading ...