Loading ...

Loading ...

Loading ...

G-Ring Maintenance

Purchasean O-Ring Repair Kit at your local Searsor by calling

1-888-4-MY-HO[VlE(469-4663} or onlineat www.sears.com.It

is not includedwith the pressurewasher.This kit includes

replacemento-rings, rubberwasher andwater inlet filter. Referto

the instructionsheetprovidedin the kit to serviceyour unit's

o-rings.

WARHIHG

The high pressure stream of water that this

,_ equipment produces can cut through skin and itsunderlying tissues, leading to serious injury and

)ossible amputation.

• NEVERrepairleakingconnectionswith sealantof anykind.

Replaceo-ringor seal.

ENGJHEMAINTENANCE

WARNING

_'_ Unintentional sparking can result in fire or

_¢ electric shock.

WHENADJUSTINGORMAKINGREPAIRSTO YOUR

PRESSUREWASHER

. Disconnectthe sparkplugwire fromthe sparkplugand place

the wire whereit cannotcontactsparkplug.

WHENTESTINGFORENGINESPARK

• Useapprovedsparkplugtester.

. DONOTcheckfor sparkwith sparkplug removed.

Oil

OffRecommendations

We recommend the use of Briggs & Stratton Warranty

Certified oils for best performance. Other high-quality

detergent oils are acceptable if classified for service SF,SG,

SH, SJ or higher. DO NOT use special additives.

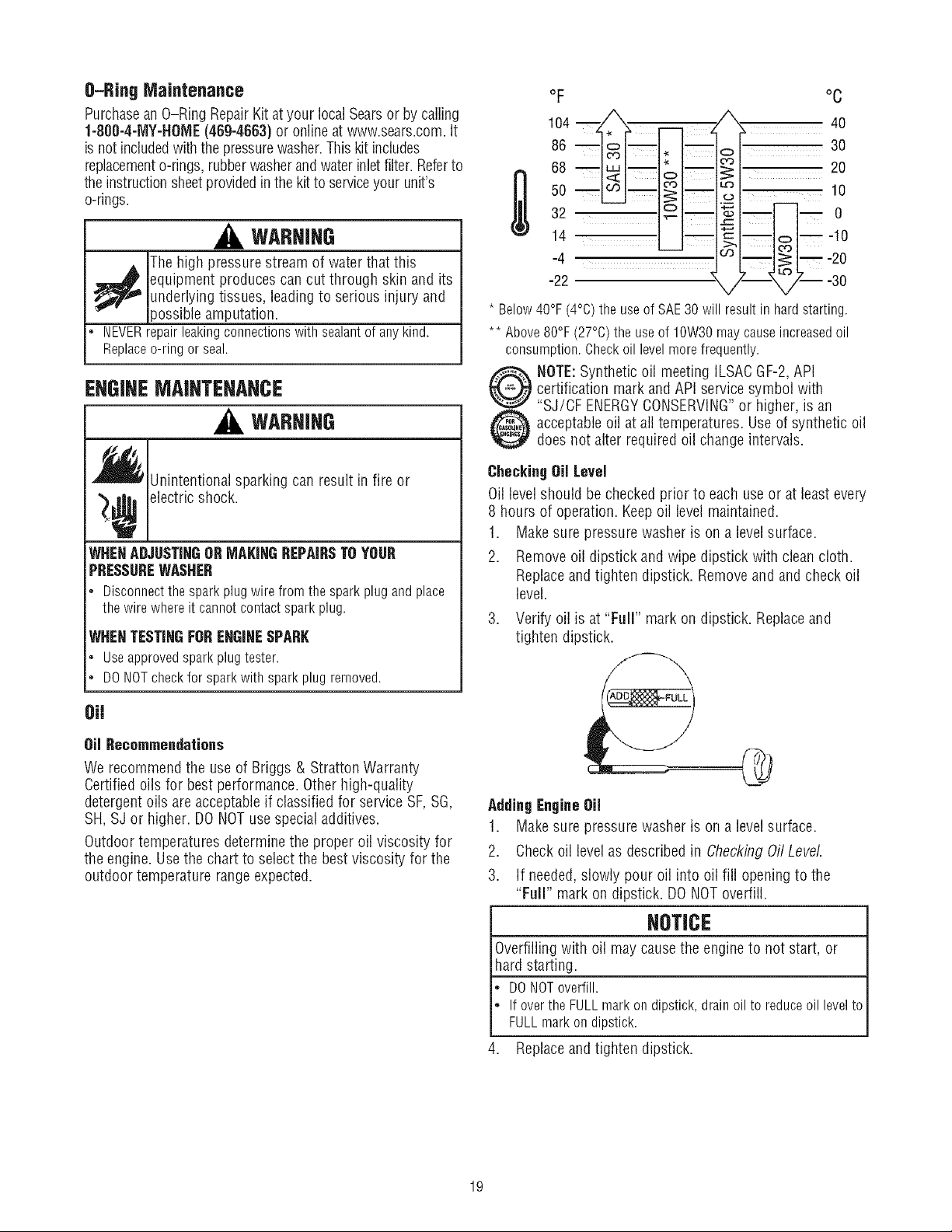

Outdoor temperatures determine the proper oil viscosity for

the engine. Usethe chart to select the best viscosity for the

outdoor temperature rangeexpected.

°F °C

104 -- -_ -- , X 40

68 2o

5o lo

32 _ -- 0

14 -10

-4 L-- o

-22 /--_-- -30

* Below40°F(4°0) the useof SAE30will resultin hardstarting.

** Above8O°F(27°C)the useof lOW30maycauseincreasedoil

consumption.Checkoil levelmorefrequently.

_ OTE:Synthetic oil meeting ILSAC GF-2,API

certification mark and API servi,cesymbol with

"SJ/CF ENERGYCONSERVING or higher, is an

acceptableoil at all temperatures. Use of synthetic oil

does not alter required oil change intervals.

CheckingOil Level

Oil level should be checked prior to each use or at least every

8 hours of operation. Keepoil level maintained.

1. Makesure pressure washer is on a level surface.

2. Remove oil dipstick and wipe dipstick with clean cloth.

Replaceand tighten dipstick. Removeand and check oil

level.

3. Verify oil is at "Full" mark on dipstick. Replaceand

tighten dipstick.

AddingEngineOil

1.

2.

3.

@

Makesure pressure washer is on a level surface.

Checkoil level as described in Checking Off Level

If needed,slowly pour oil into oil fill opening to the

"Full" mark on dipstick. DO NOT overfill.

NOTICE

Overfilling with oil may causethe engine to not start, or

hard starting.

DONOToverfill.

Ifoverthe FULLmarkon dipstick,drainoil to reduceoil levelto

FULLmarkon dipstick.

4. Replaceand tighten dipstick.

19

Loading ...

Loading ...

Loading ...