Loading ...

Loading ...

Loading ...

.

.

Disconnectthe logcradlefromthe beamon the sideof the control

valve.See Figure3-5.

Liftand slidethe cylinderup to the topof beamand intothe weld

brackets.

5. Attachthedislodgeroverthe wedgeassemblyand secureit to the

weldbracketswith the previouslyremovedhardware.

NOTE:Oncethe sixhex screwsaretightened,theremay be a slight

gapbetweenthe dislodgerand the weldbrackets.Thisgapis normal.

6. Reattachthe logcradleto the side of the beamwith the control

valve,aligningthe endsof the cradlewith the beamflanges.

7. Rollthe log splitteroff the bottomcrate.

PREPARING THE LOG SPLITTER

1. Lubricatethe beamarea (wherethe splittingwedgewill slide)with

engineoil. Do notuse grease.

2. Removethevented reservoirdipstick,which is locatedinfrontof

the engineon top of the reservoirtank. See Figure3-6.

IMPORTANT:The logsplittermayhavebeenshippedandprimedwith

hydraulicfluidin the reservoirtank. However,you MUSTcheckthe

fluidlevelbeforeoperating.If the reservoir tank is not filled, proceed

withthe followingsteps:

.

.

Fill the reservoirtankwiththe hydraulicfluidincludedwith this

machine(if equipped)or oneof theapprovedfluidswhichinclude

Dexron®III / Mercon®automatictransmissionfluid ora 10Weight

AWhydraulicoil.

Checkthefluid levelusingthedipstick.SeeFigure3-6. Do not

overfill.

.

Replacetheventeddipsticksecurely,tighteningit untilthe topof

the threadsare flush with top of the pipe.

6. Disconnectthe spark plugand primethe pumpby pullingthe recoil

starteras faras it will go. Repeatapproximately10times.

7. Reconnectthe sparkplugwireandstart the enginefollowingthe

instructionsin the OPERATIONsection.

8. Use thecontrol handleto engagethewedgeto the farthest

extendedposition.Then retractthe wedge.

9. Refillthe tankas specifiedon thedipstick.

NOTE:Failureto refillthe tankwill voidthe warranty.

10.Extendand retractthewedge 12completecyclesto removeanyair

trappedin the system(the systemis "self-bleeding").

11.Refillthe reservoirwithinthe rangemarkedon the dipstick.

Muchd the originalfluid hasbeendrawnintothe cylinderand hoses.

Makecertainto refillthe reservoirto preventdamageto the hydraulic

pump.

NOTE:Somefluid may overflowfromthe vent plug as the system

buildsheatand the fluidexpandsandseeksa balancedlevel.

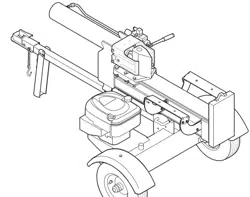

Figure 3=4

Figure 3=5

\\\

"x

\

\

Figure 3=6

,J

9

Loading ...

Loading ...

Loading ...