Loading ...

Loading ...

Loading ...

HYDRAULIC FLUID AND iNLET FILTER

Checkthehydraulicfluid levelin the logsplitterreservoirtank

beforeeach use. Maintainthe fluidlevelwithinthe rangespecified

onthe dipstickat all times.

Changethe hydraulicfluid inthe reservoirevery 100 hoursof

operation.Followthe stepsbelow:

Disconnectthe suctionhosefromthe bottomof the reservoirtank.

2. Carefullyunthreadthe inletfilter and clean it with penetratingoil.

SeeFigure5-2.

3. Allowthefluid to drain intoa suitablecontainer.

4. Reinsertthe filterandrefillthe reservoirwith three(3) gallonsof oil.

Approvedfluids includeDexron®III/Mercon® automatictransmis-

sionfluid ora 10WeightAWhydraulicoil.

• Maintainthe fluid levelwithinthe rangespecifiedon the dipstickat

alltimes.

NOTE:Alwaysdisposeof usedhydraulicfluidand engineoilat

approvedrecyclingcentersonly.

• Contaminantsin fluidmaydamagethe hydrauliccomponents.

Flushingthe reservoirtank and hoseswithkerosenewhenever

serviceisperformedon the tank, hydraulicpumpor valve is

recommended.Any repairto the hydrauliccomponentsshouldbe

performedby a SearsServiceCenter.

USE EXTREME CAUTIONWHEN WORKING WITH KEROSENE. IT IS AN EXTREMELY

FLAMMABLEFLUID.

Hydraulic Filter

• Changethe hydraulicfilterevery50 hoursof operation.Useonly a

10micronhydraulicfilter.Orderpart number723-0405.

BEAM AND SPLITTING WEDGE

Beforeeach use,lubricatebothsides of the beam(whereit comes

intocontactwith the splittingwedge)withengineoil. The wedge

plateon the log splitterisdesignedsothe gibs on the sideof the

wedgeplatecan be removedandrotatedand/orturnedoverfor

evenwear.

• Makecertain to readjustthe adjustmentbolts sothe wedgemoves

freely,but no excessspaceexists betweenthe wedgeplateand the

beam.

/

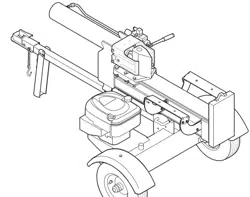

Figure 5=2

ENGINE

Check Engine Oil

1. Stoptheengineandwait severalminutesbeforecheckingtheoil

level.

2. Removethe oilfill dipstick.

3. Checkthe oil levelon the dipstick.With the engineon levelground,

the oil mustbeto the FULLmarkon thedipstick.

4. Replacethe dipstickand tighten.

Changing Engine Oil

Onlyusehigh quality detergentoil ratedwith API serviceclassification

SF,SG, or SH.Selecttheoil's SAEviscositygrade accordingto the

expectedoperatingtemperature.Followthechart below:

Warmer

5W30

SAE 30

0il Viscosity Chart

17

Loading ...

Loading ...

Loading ...