Loading ...

Loading ...

Loading ...

20

Keep all screws, nuts, washers, gaskets, and electrical fittings removed during repair procedures.

These parts usually are not provided with replacement kits.

Test repairs after problems are corrected.

If sprayer does not operate properly, review repair procedure to verify you did it correctly. See

Troubleshooting, page 20.

Overspray may build up in the air passages. Remove any overspray and residue from air passages

and openings in the enclosures whenever you service sprayer.

Do not operate the sprayer without the motor shroud in place. Replace if damaged. Motor shroud

directs cooling air around motor to prevent overheating and insulates the control board from

accidental electric shock.

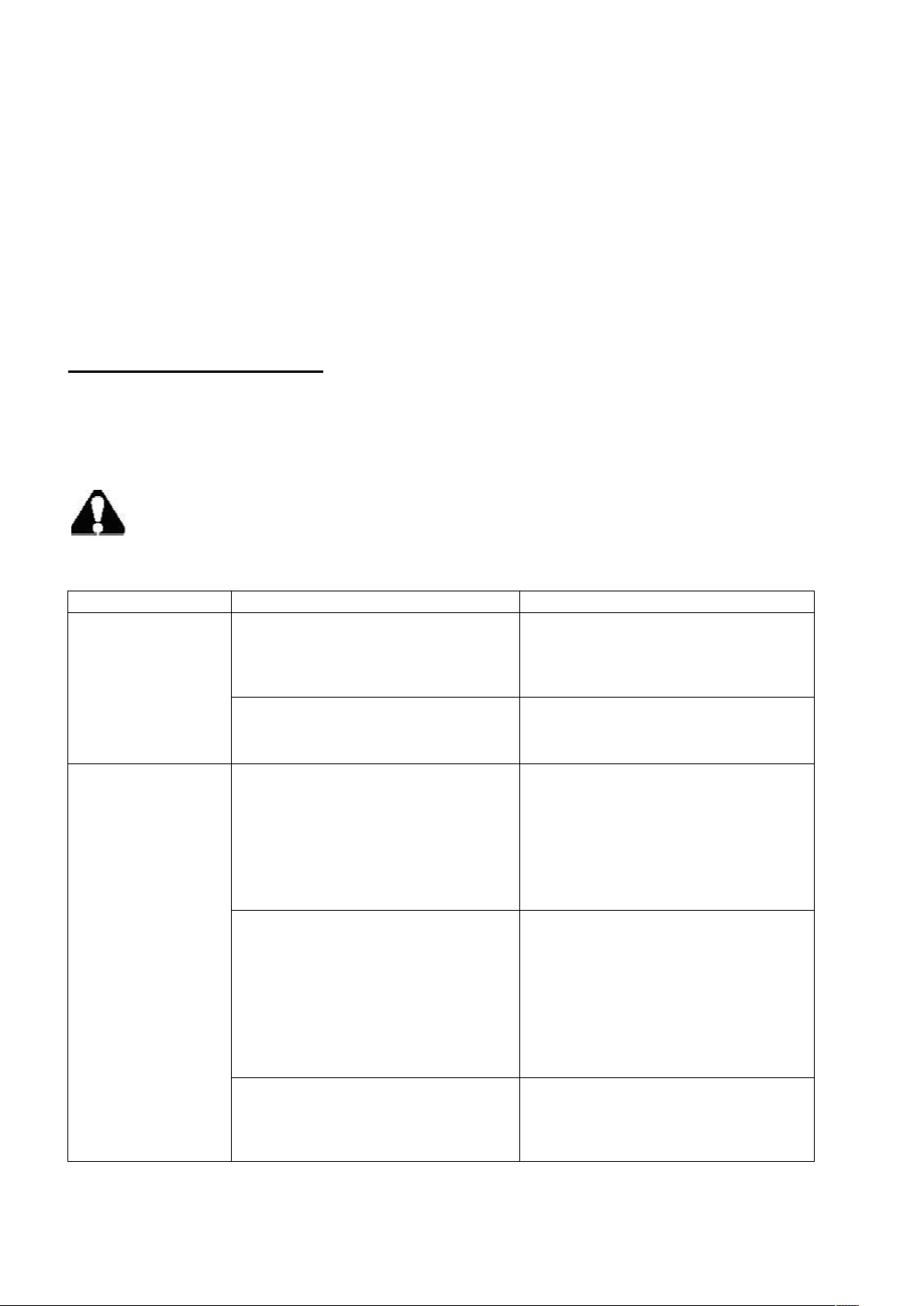

TROUBLE SHOOTING

The following form lists the common operating system with problem and solutions. Please read the form

carefully and follow it.

WARNING: If any of the following symptoms appears during your operating, stop using the

tool immediately, or serious personal injury could result. Only a qualified persons or an

authorized service center can perform repairs or replacement of tool.

PROBLEMS

POSSIBLE CAUSES

REMEDIES

Basic Fluid Pressure

1. Pressure control knob setting.

Motor will not run if set at minimum

(fully counter-clockwise).

1.Slowly increase pressure setting to

see if motor starts

2. Spray tip or fluid filter may be

clogged.

2.Relieve pressure ,then Then clear

clog or clean gun filter

Basic Mechanical

1. Pump frozen or hardened paint 1.Thaw sprayer if water or

water-based paint has frozen in

sprayer. Place sprayer in warm

area to thaw. Do not start sprayer until

thawed completely. If paint hardened

(dried) in sprayer,replace pump

packings.

2. Displacement pump connecting

rod pin.

Pin must be completely pushed into

connecting rod and retaining

spring must be firmly ingroove or

pump pin.

2. Push pin into place and secure with

spring retainer.

3. Motor. Remove drive housing

assembly.

3. Replace motor if fan won’t turn.

Loading ...

Loading ...

Loading ...