Loading ...

Loading ...

Loading ...

33

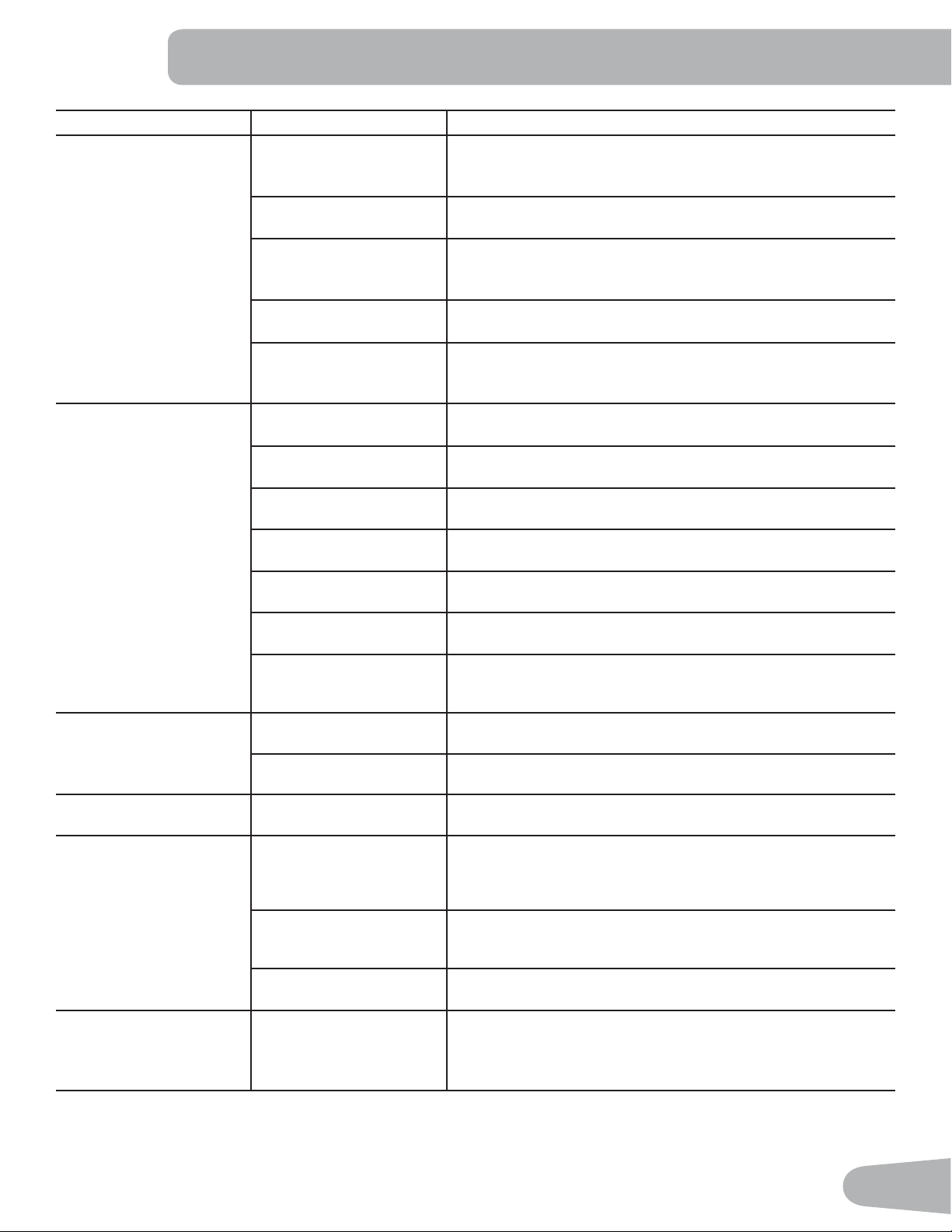

Condition/Problem Things to Check Solution

Resistance does not

change (machine turns on

and operates)

Check Console Check for visual sign that Console is damaged. Replace Con-

sole if damaged.

Check data cable integrity All wires in cable should be intact. If any are visibly crimped or

cut, replace cable.

Check data cable

connections/orientation

Be sure cable is connected securely and oriented properly.

Reseat all connections. Small latch on connector should line up

and snap into place.

Check Servo Motor

(requires shroud removal)

If magnets move, adjust until they are within the proper range.

Replace Servo Motor if not functioning properly.

If the above steps do not resolve the problem, contact Cus-

tomer Service (if inside US/Canada) or your local distributor (if

outside US/Canada) for further assistance.

Console shuts off (enters

sleep mode) while in use

Check electrical (wall)

outlet

Make sure unit is plugged into a functioning wall outlet.

Check connection at front

of unit

Connection should be secure and undamaged. Replace

adapter or connection at unit if either are damaged.

Check data cable integrity All wires in the cable should be intact. If any are cut or crimped,

replace cable.

Check data cable

connections/orientation

Be sure cable is connected securely and oriented properly.

Small latch on connector should line up and snap into place.

Reset machine Unplug unit from electrical outlet for 3 minutes. Reconnect to

outlet.

Check magnet position

(requires shroud removal)

Magnet should be in place on pulley.

Check Speed Sensor

(requires shroud removal)

Speed sensor should be aligned with magnet and connected to

data cable. Realign sensor if necessary. Replace if there is any

damage to the sensor or the connecting wire.

Unit rocks/does not sit

level

Check leveler adjustment Adjust levelers until machine is level.

Check surface under unit Adjustment may not be able to compensate for extremely un-

even surfaces. Move machine to level area.

Foot pedals loose/unit

dif¿cult to operate

Hardware Tightly secure all hardware on the Pedal Arms and Handlebar

Arms.

Drive train click/tick

noise once per full crank

revolution

Check crank/pulley

assembly

Disconnect left and right foot assemblies and rotate crank. If

sound persists, replace crank/pulley assembly. If sound does

not come from rotating crank, check foot assemblies and up-

per/lower handlebars.

Check foot assemblies,

leg assemblies, handlebar

assemblies

Manually move foot, leg, and handlebar assemblies to isolate

sound. Replace part making sound.

Check for loose hardware Tightly secure all hardware on the Stabilizers and the base of

the Console Mast.

Knocking sound during

machine operation

Check hardware at

junction between Lower

Handlebar Arms, Pedals,

and Legs

Make sure that the hardware is clear of any debris.

Loading ...

Loading ...

Loading ...