Loading ...

Loading ...

Loading ...

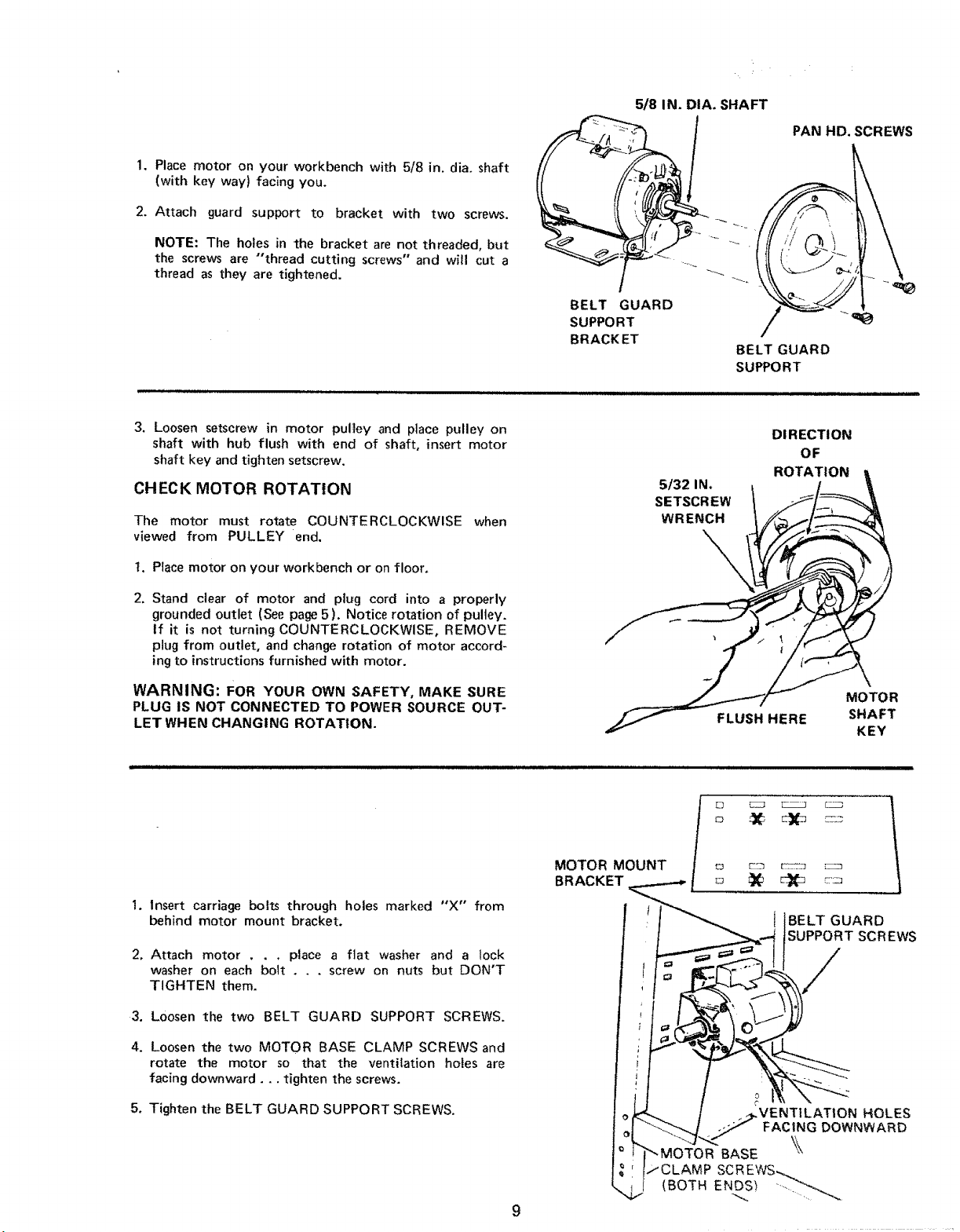

1. Place motor on your workbench with 5/8 in. dia. shaft

(with key way) facing you.

2. Attach guard support to bracket with two screws.

NOTE: The holes in the bracket are not threaded, but

the screws are "thread cutting screws" and will cut a

thread as they are tightened.

5/8 IN. DIA. SHAFT

BELT GUARD

SUPPORT

BRACK ET

BELT GUARD

SUPPORT

PAN HID. SCREWS

3, Loosen setscrew in motor pulley and place pulley on

shaft with hub flush with end of shaft, insert motor

shaft key and tighten setscrew.

CHECK MOTOR ROTATION

The motor must route COUNTERCLOCKWISE when

viewed from PULLEY end.

1. Place motor on your workbench or on floor,

2. Stand clear of motor and plug cord into a properly

grounded outlet (See page 5). Notice rotation of pulley.

If it is not turning COUNTERCLOCKWISE, REMOVE

plug from outlet, and change rotation of motor accord-

ing to instructions furnished with motor.

WARNING: FOR YOUR OWN SAFETY, MAKE SURE

PLUG IS NOT CONNECTED TO POWER SOURCE OUT-

LET WHEN CHANGING ROTATION.

5/32 IN,

SETSCREW

WRENCH

\,

DIRECTION

OF

ROTATION

FLUSH HERE

MOTOR

SHAFT

KEY

1. Insert carriage bolts through holes marked "X" from

behind motor mount bracket.

2, Attach motor . . , place a flat washer and a lock

washer on each bolt . . . screw on nuts but DON'T

TIGHTEN them.

3. Loosen the two BELT GUARD SUPPORT SCREWS.

4. Loosen the two MOTOR BASE CLAMP SCREWS and

rotate the motor so that the ventilation holes are

facing downward.., tighten the screws.

5. Tighten the BELT GUARD SUPPORT SCREWS.

9

MOTOR MOUNT

BRACKET

o

BELT GUARD

SCREWS

/

.VENTILATION HOLES

FACING DOWNWARD

BASE

JCLAMP SCREWS

(BOTH ENOS_ _

Loading ...

Loading ...

Loading ...