Loading ...

Loading ...

Loading ...

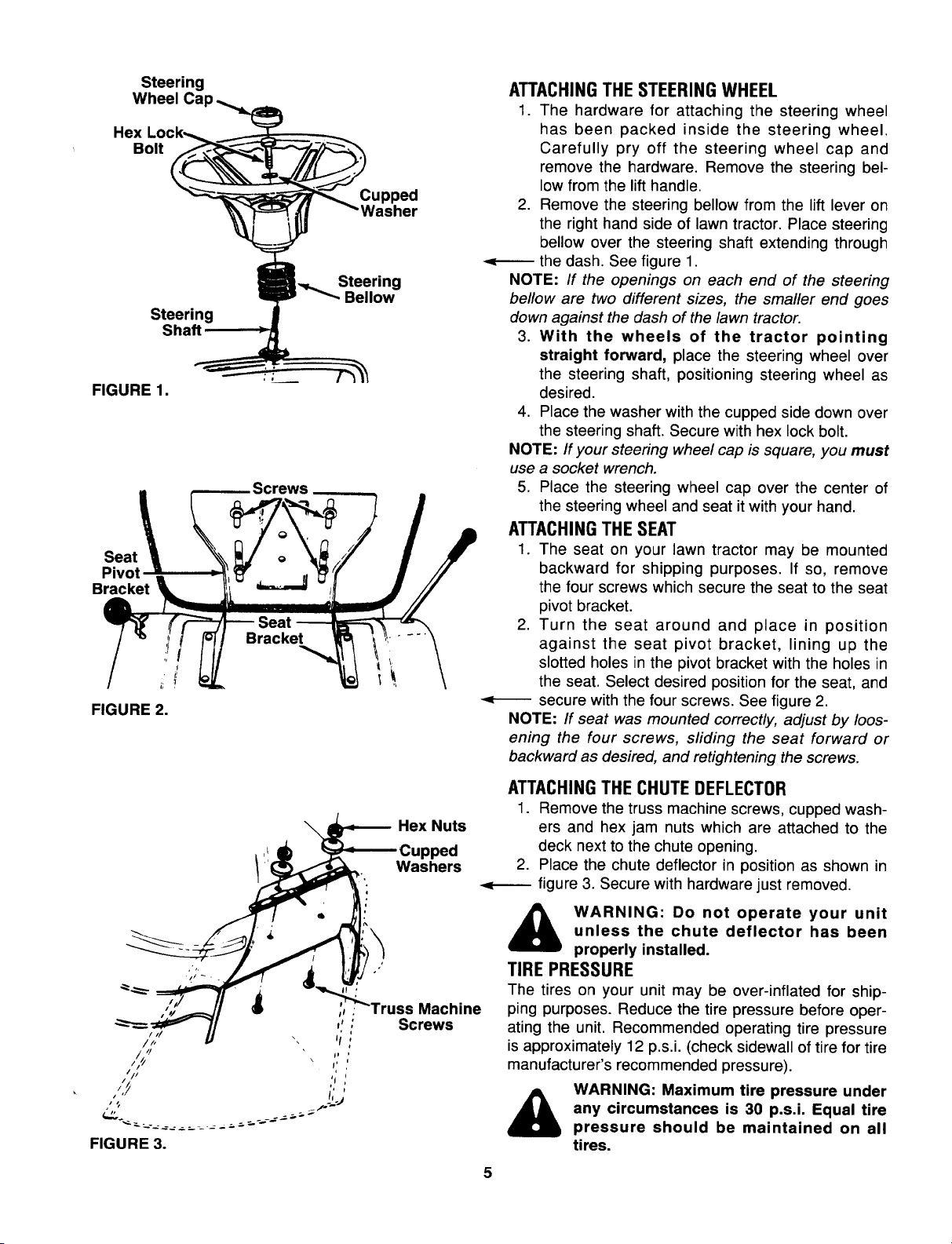

Steering

Wheel Ca

Hex

Bolt

Steering

Shaft

FIGURE 1.

Screws

Seat

Pivot

Bracket

1

FIGURE 2.

\

Steering

Bellow

Hex Nuts

Cupped

Washers

Machine

Screws

ATTACHINGTHE STEERING WHEEL

1. The hardware for attaching the steering wheel

has been packed inside the steering wheel.

Carefully pry off the steering wheel cap and

remove the hardware. Remove the steering bel-

low from the lift handle.

2. Remove the steering bellow from the lift lever on

the right hand side of lawn tractor. Place steering

bellow over the steering shaft extending through

the dash. See figure 1.

NOTE: If the openings on each end of the steering

bellow are two different sizes, the smaller end goes

down against the dash of the lawn tractor.

3. With the wheels of the tractor pointing

straight forward, place the steering wheel over

the steering shaft, positioning steering wheel as

desired.

4. Place the washer with the cupped side down over

the steering shaft. Secure with hex lock bolt.

NOTE: If your steering wheel cap is square, you must

use a socket wrench.

5. Place the steering wheel cap over the center of

the steering wheel and seat it with your hand.

ATTACHINGTHE SEAT

1. The seat on your lawn tractor may be mounted

backward for shipping purposes. If so, remove

the four screws which secure the seat to the seat

pivot bracket.

2. Turn the seat around and place in position

against the seat pivot bracket, lining up the

slotted holes in the pivot bracket with the holes in

the seat. Select desired position for the seat, and

secure with the four screws. See figure 2.

NOTE: If seat was mounted correctly, adjust by loos-

ening the four screws, sliding the seat forward or

backward as desired, and retightening the screws.

ATTACHINGTHE CHUTE DEFLECTOR

1. Remove the truss machine screws, cupped wash-

ers and hex jam nuts which are attached to the

deck next to the chute opening.

2. Place the chute deflector in position as shown in

figure 3. Secure with hardware just removed.

WARNING: Do not operate your unit

unless the chute deflector has been

properly installed.

TIREPRESSURE

The tires on your unit may be over-inflated for ship-

ping purposes. Reduce the tire pressure before oper-

ating the unit. Recommended operating tire pressure

is approximately 12 p.s,i, (check sidewall of tire for tire

manufacturer's recommended pressure).

&

WARNING: Maximum tire pressure under

any circumstances is 30 p.s.i. Equal tire

pressure should be maintained on all

tires.

5

Loading ...

Loading ...

Loading ...