Loading ...

Loading ...

Loading ...

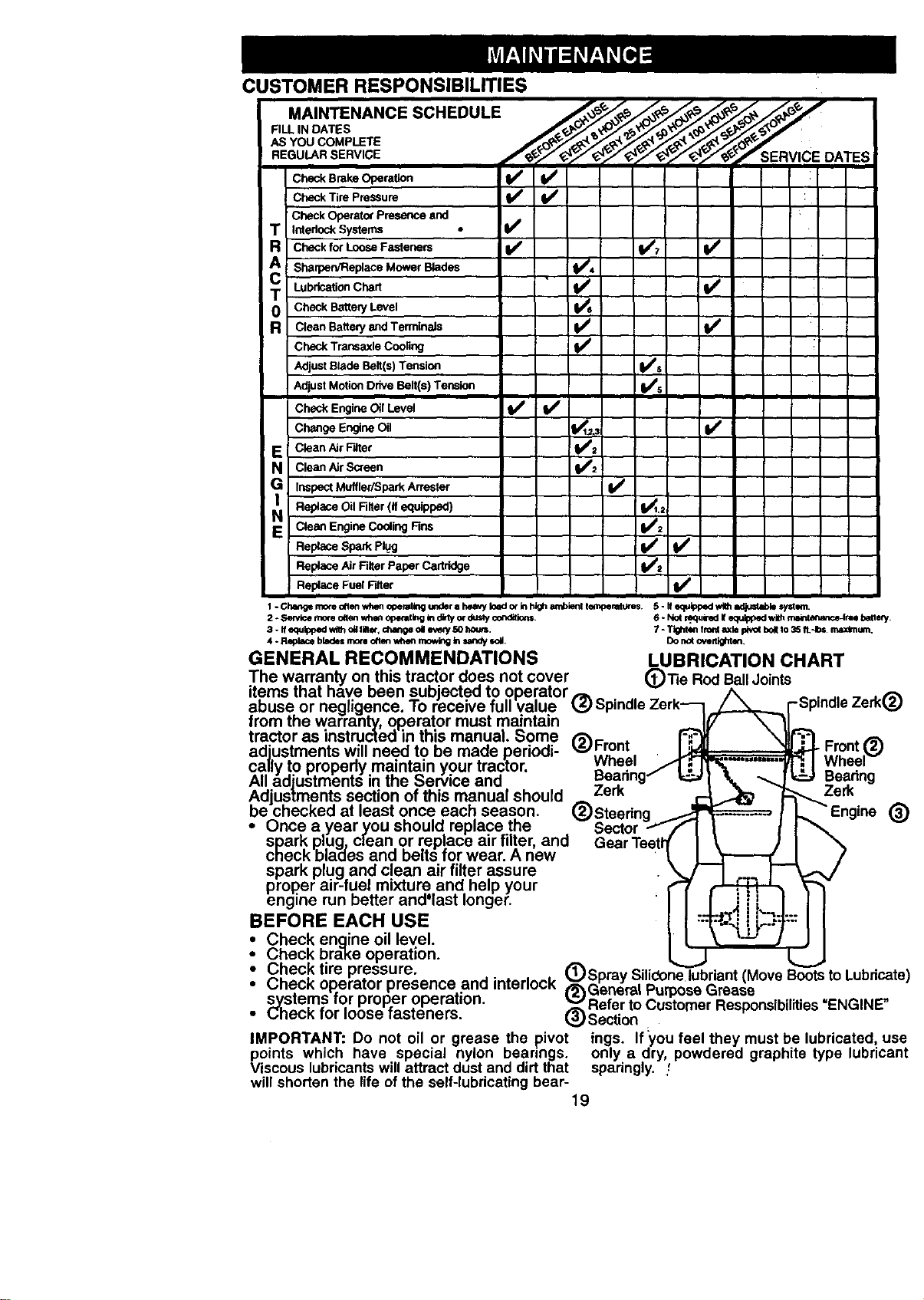

CUSTOMER RESPONSIBILITIES

MAINTENANCE SCHEDULE

AS YOU COMPLETE _"_.(I_€_

Check Operator PresSr(wceand

T I_edock Systems * V'

R Check for Loose Fasteners If 1#17 t#€

Sharpen/Replace Mower Blades

T LubricationChart I# €

0 Check Battery Level

R Clean Battery and Termin_ds I##

Check Trsnsaxle Cooling If

AdjustBlade Belt(s)Tension ll_s

AdjustMotion Drive Belt(s) Tension V's

Check Engine Oil Level _ li_

Ei Clean Air Fdter _:

N Clean Air Soreen

G Inspect MuffledSpark Arrester

Replace Oil Filter(If equipped) l_t;

N Cleon Engine Cooling Fins _2

Repl_,e Spark pl_g

Replace Air FilterPaper Cartridge

Replace Fuel Fdter If

1. Change_ oftenwheno_oe.dlngundera heavyloador inhighambientlemperettwes. 5 - ffequippedv,_h_justable systore.

2 *_ moqeoSenv_en op4md_g _ dtdyorduslyo0nd_ions. 6. Not reqund I e_/_ppedwithnW_anance-f_l Mflery

3 - Ifeo_lppodwflho_ lllte¢,chmlgeo_1eveP/50 hour_. 7* Tightenfmrdaxle pM_ bol Io 35 fL-I_ msdmum.

4. Re#lace bladesmo_ oftenv.t_n mowtn9In_nW so_ Do notovertlghtee.

GENERAL RECOMMENDATIONS LUBRICATION CHART

The warranty on this tractor does not cover (T)Tie Rod Ball Joints

items that have been subjected to operator .,-= v

abuse or negligence. To receive full value (,_Spindle

Irom the warranty, operator must maintain

tractor as instructea in this manual. Some _Fron"

adjustments will need to be made periodi- _'_wh,,_,

cally to propeny maintain your tractor. :.""_."

pearl

All adjustments in the Service and Zerk

Adjustments section of this manual should

be checked at least once each season.

®

• Once a year you should replace the .

spark plug_ clean or replace air filter, ana

cneck blaaes and belts [or wear. A new

spark plug an.d clean air filter .assure

proper air-fuel mixture and heup your

engine run better and'last longer.

BEFORE EACH USE

Zerk-----_ p----,_I-r_Spindle Zerk(_)

I Front ._

'_, J Wheel

Bearing--" _ | _ _ | _ Bearing

Zar,

(_)Steering I I-..-Engine

Sector-Ill I I I

Gear Teet_

• Check engine oil level.

Check brake operation.

Check tire pressure. _ . . (_)Spray SiliConelubriant (Move Bootsto Lubricate)

Check op,erator presence ana interlocK t'_General Purpose Grease

svstems ror proper operation. ,_ Refer to Customer Responsibilities ENGINE"

L;neck for loose rasteners. _ Section

IMPORTANT: Do not oil or grease the pivot ings. If_,ou feel they must be lubricated, use

points which have special nylon bearings, only a dry, powdered graphite type lubricant

Viscous lubricants will attract dust and dirt that sparingly.

will shorten the life of the self-lubricating bear-

19

Loading ...

Loading ...

Loading ...