Loading ...

Loading ...

Loading ...

11

English

8-3 SPECIFICATION FOR FIELD SUPPLY FUSES

AND WIRING

Model

Power supply wiring

Remote controller wiring

Transmission wiring

Fuse

Size Wire Size

FCQ18TAVJU

15A

Wiring size

and length

must

comply

with local

codes.

2-conductor,

stranded

non-shielded

copper cable

PVC/vinyl

jacket

(NOTE)

AWG18-16

(0.75-

1.25 mm

2

)

FCQ24TAVJU

FCQ30TAVJU

FCQ36TAVJU

FCQ42TAVJU

FCQ48TAVJU

Allowable lengths of transmission wiring and remote controller

wiring are as follows.

(1) Outdoor unit – Indoor unit

.................... Max. 3280 ft (1,000 m)

(2)

Indoor unit – Remote controller .............. Max. 1640 ft (500 m)

NOTE

• Vinyl cord with sheath or cable (Insulated thickness :

1/16 in. (1 mm) or more)

8-4 WIRING CONNECTION METHOD

CAUTION FOR WIRING

• The indoor units in the same system can be connected to

the power supply from one branch switch. How ever, selec-

tion of branch switch, branch over current circuit breaker

and wiring size must be according to applicable legislation.

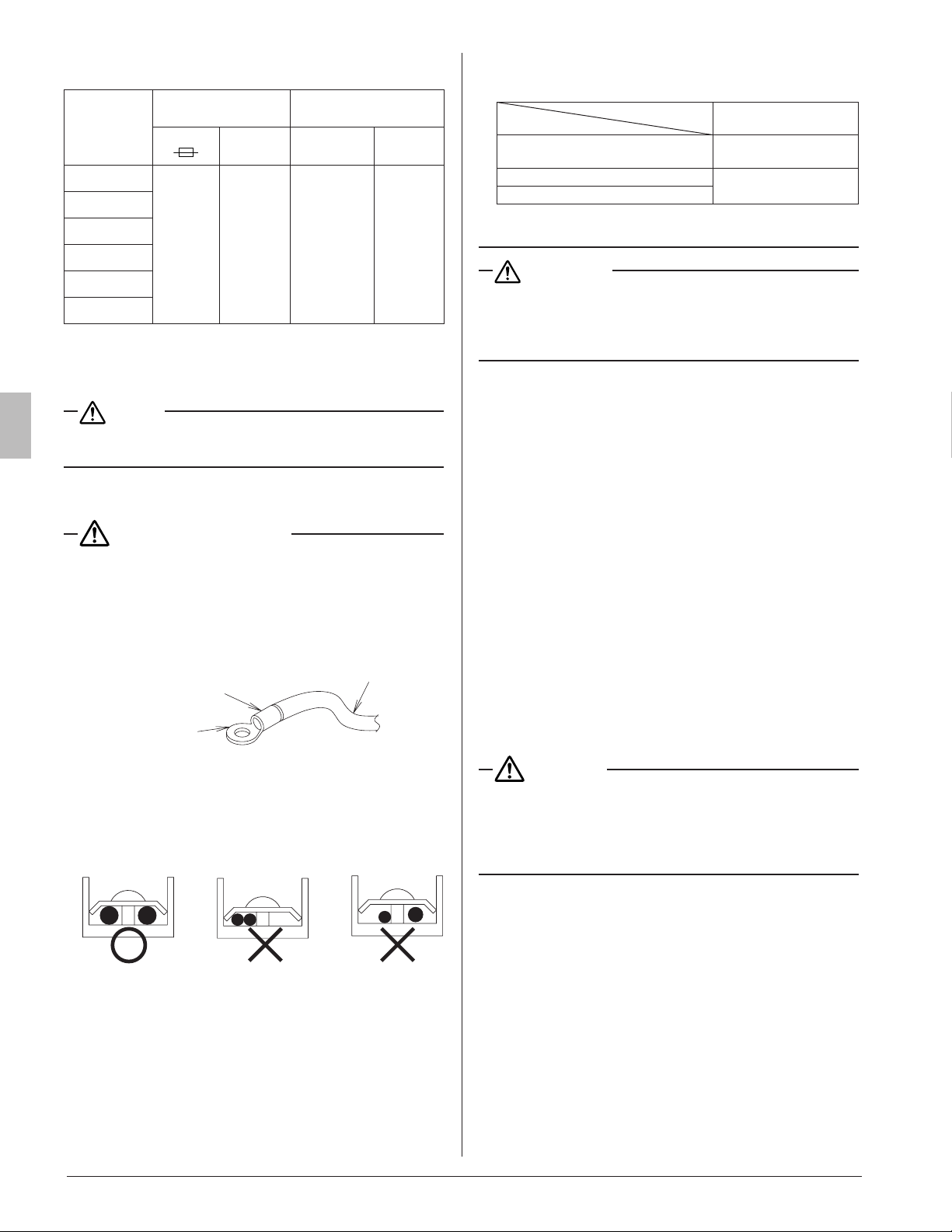

• For connection to the terminal block, use a ring type crimp

style terminals with insulation sleeve or insulate the wirings

properly.

Insulation sleeve

Ring type crimp

style terminals

Wiring

• If the above is not available, make sure to fulll the following

requirements.

Connection of 2

wirings of same

size must be

carried out on

both sides.

Connection of

wirings of

different sizes is

prohibited.

Connection of 2

wirings on one

side is

prohibited.

(Abnormal heating may occur if the wirings are not tight-

ened securely.)

• Use the required wirings, connect them securely and x

these wirings securely so that external force may not apply

to the terminals.

• Use a proper screw driver for tightening the terminal

screws.

If an improper screw driver is used, it may damage the

screw head and a proper tightening cannot be car ried out.

• If a terminal is over tightened, it may be damaged.

Refer to the table shown below for tightening torque of

terminals.

Tightening torque

[lbf·ft. (N·m)]

Terminal block for remote controller

and transmission wirings

0.65 ± 0.06

(0.88 ± 0.08)

Terminal for power supply

0.96 ± 0.07

(1.3 ± 0.1)

Ground terminal

• Do not carry out soldering nish when stranded wirings

are used.

WARNING

• When wiring, form the wirings orderly so that the control

box cover can be securely fastened. If the control box cover

is not in place, the wirings may oat up or be sandwiched by

the box and the lid and cause electric shocks or a re.

<Powersupplywiring·groundwiring·remotecontroller

wiring·transmissionwiringconnectingmethod>

• Power supply wiring, ground wiring

Pass the power supply wire through the attached insula-

tion tube (16) between the outlet of conduit and the power

supply terminal, and bind them together with the attached

clamp (4). (Refer to Fig. 23-2)

Use a pair of conduit mounting plates (17) to connect a

conduit to the unit as shown Fig. 23-1. After connecting the

power supply wiring to [L

¹

· L

²

] on the power supply terminal

block (X2M) and the ground wiring to the ground terminal,

clamp them near the terminal block using the attached

clamp (4). (Refer to Fig. 23-2)

Remote controller wiring, transmission wiring

Pull the wiring through the wiring penetrating hole (low volt-

age). After connecting the remote controller wir ing to [P

¹

·

P

²

] and the transmission wiring to [F

¹

· F

²

] on the terminal

block (X1M), clamp them near the terminal block using the

attached clamp (4). (Refer to Fig. 23-2)

• After connecting the wiring, make sure to stick the sealing

material (Small) (13) to the wiring penetrating hole to pre-

vent water from entering the indoor unit. (RefertoFig.24)

CAUTION

•

Never connect the power supply wiring to the terminal

block for remote controller/transmission wiring (X1M).

If may damage the total system.

• Do not connect the remote controller/transmission wir-

ing to the wrong terminal block.

01_EN_3P161684-9U.indd 11 8/8/2018 15:26:56

Loading ...

Loading ...

Loading ...