Loading ...

Loading ...

Loading ...

MAINTENANCE/SERVICE

169304 158 Rev. C

57.9.6 Traction Drive Hydraulics

57.9.6.1 Transmission Oil Pressure

The windrower transmission consists of two

variable displacement axial piston hydraulic

pumps, one for each drive wheel. The pumps

are direct driven through a coupling to the

engine. Each pump requires charge flow to

make up for internal leakage, maintain positive

pressure in the main circuit, provide flow for

cooling and replace any leakage losses from

external valving or auxiliary systems. The

charge pressure is monitored and if it drops

below 150 psi (1035 kPa), the CDM sounds a

tone and displays a flashing warning. Refer to

Section 5.17.4 Warnings and Alarms.

IMPORTANT

Rated charge pressure must be

maintained under all conditions of

operation to prevent damage to the

transmission.

If the TRANS OIL PRESSURE warning is

displayed, shutdown the engine and proceed as

follows:

a. Check the hydraulic fluid level in the tank. Refer

to Section 7.11.1 Oil Level.

b. Check the hoses and lines for leakage.

c. Check the charge pressure relief valve. Refer to

following section.

d. If charge pressure still cannot be maintained, do

not operate the windrower. Contact your

windrower dealer.

57.9.6.2 Charge Pump Pressure

Incorrect charge pressure settings may result in

the inability to build required system pressure

and/or inadequate loop flushing flows. Correct

charge pressure must be maintained under all

conditions to maintain pump control

performance and to operate the brake release

Check and adjust charge pump pressure as

follows:

DANGER

Stop engine and remove key from ignition

before leaving operator's seat for any

reason. A child or even a pet could engage

an idling machine.

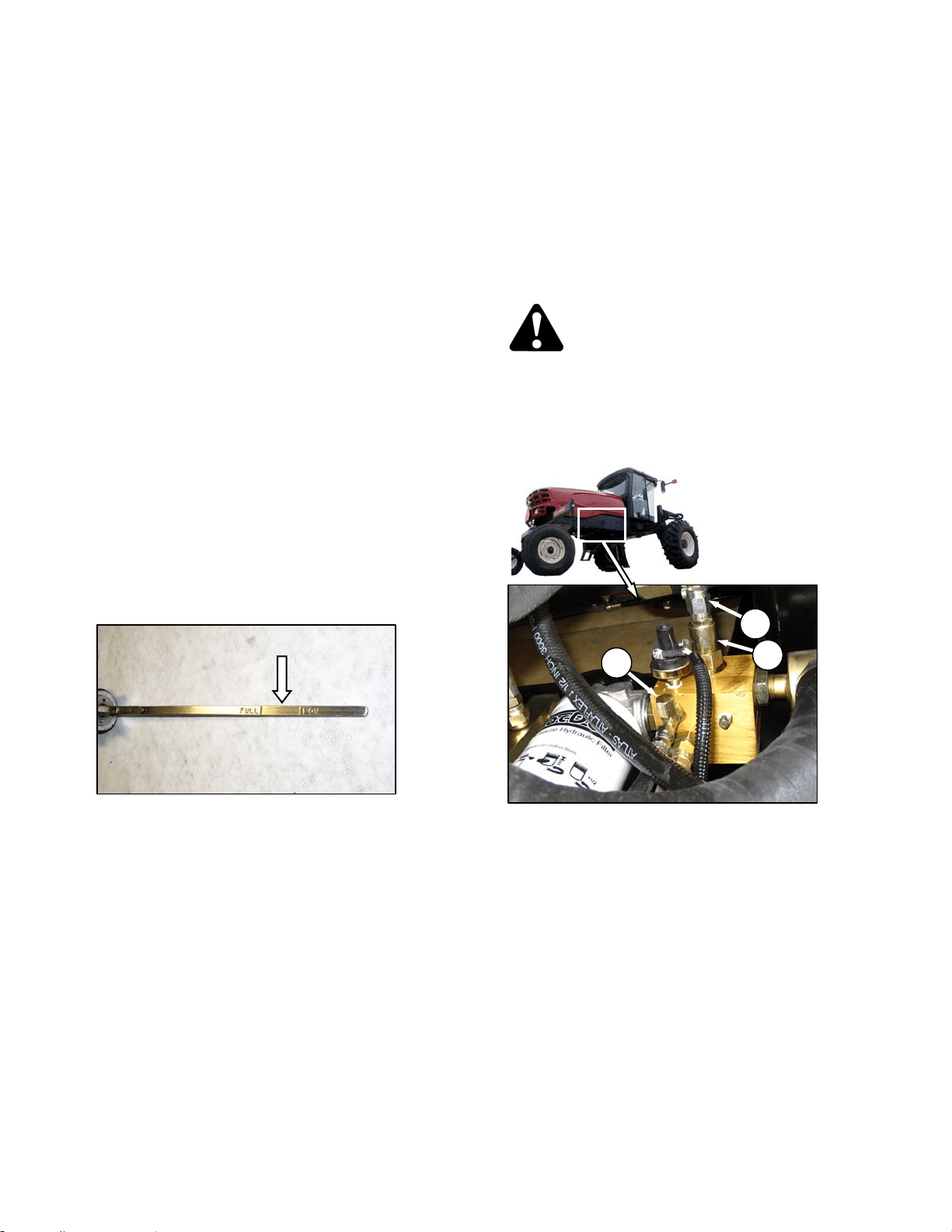

a. Open engine compartment hood fully.

b. Remove cap (A) at fitting.

c. Attach a 0 - 600 psi (4000 kPa) pressure gauge

to a hose that is long enough to allow pressure

gauge to be read from the operator's seat.

Attach hose to the fitting.

d. Start engine and leave at idle. Pressure should

be 200 to 250 psi (1379 to 1724 kPa) with the

hydraulic oil at 100°F. (40°C) minimum.

e. If pressure is not within this range, adjust relief

pressure as follows:

1. Shut off engine and remove key.

2. Remove cap (C) from relief valve (B) for

access to adjustment screw.

(continued next page)

A

C

B

Loading ...

Loading ...

Loading ...