Loading ...

Loading ...

Loading ...

FrictionWheelRubber

Replace the friction wheel rubber if any signs of wear or

cracking are found. Follow instructions below to replace

the rubber.

Tip the snow thrower up and forward, so that it rests

on housing. Refer to Figure 17.

Remove six self-tapping screws from the frame

cover underneath the snow thrower.

Remove the click pins which secure the wheels,

and remove the wheels from the axle.

Using a wrench to hold the shaft, loosen, but do not

completely remove, the hex nut and bell washer on

the left end of gear shaft. See Figure 29.

Figure 29

Lightly tap the hex nut to dislodge the ball bearing

from the right side of the frame. Remove the hex

nut and bell washer from the left end of the shaft.

Slide the gear shaft to the right, then slide the

friction wheel assembly from the shaft.

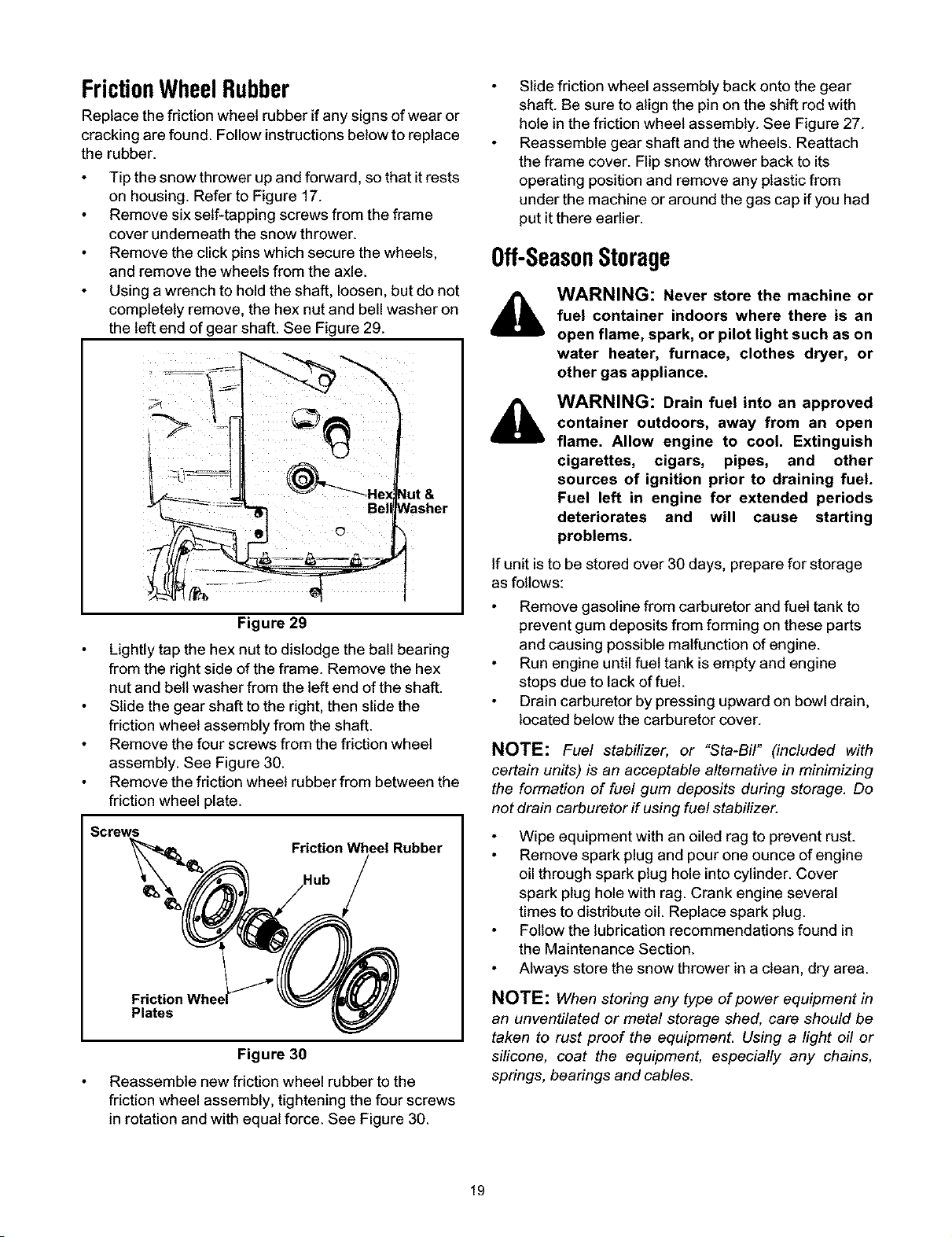

Remove the four screws from the friction wheel

assembly. See Figure 30.

Remove the friction wheel rubber from between the

friction wheel plate.

Screws

Friction Wheel Rubber

Friction Whe

Plates

Figure 30

Reassemble new friction wheel rubber to the

friction wheel assembly, tightening the four screws

in rotation and with equal force. See Figure 30.

Slide friction wheel assembly back onto the gear

shaft. Be sure toalign the pin on the shift rod with

hole in the friction wheel assembly. See Figure 27.

Reassemble gear shaft and the wheels. Reattach

the frame cover. Flip snow thrower back to its

operating position and remove any plastic from

under the machine or around the gas cap if you had

put it there earlier.

Off-SeasonStorage

WARNING: Never store the machine or

fuel container indoors where there is an

open flame, spark, or pilot light such as on

water heater, furnace, clothes dryer, or

other gas appliance.

WARNING: Drain fuel into an approved

container outdoors, away from an open

flame. Allow engine to cool. Extinguish

cigarettes, cigars, pipes, and other

sources of ignition prior to draining fuel.

Fuel left in engine for extended periods

deteriorates and will cause starting

problems.

If unit isto be stored over 30 days, prepare for storage

as follows:

Remove gasoline from carburetor and fuel tank to

prevent gum deposits from forming on these parts

and causing possible malfunction of engine.

Run engine until fuel tank is empty and engine

stops due to lack of fuel.

Drain carburetor by pressing upward on bowl drain,

located below the carburetor cover.

NOTE: Fuel stabilizer, or "Sta-Bil" (included with

certain units) is an acceptable alternative in minimizing

the formation of fuel gum deposits during storage. Do

not drain carburetor if using fuel stabilizer.

Wipe equipment with an oiled rag to prevent rust.

Remove spark plug and pour one ounce of engine

oil through spark plug hole into cylinder. Cover

spark plug hole with rag. Crank engine several

times to distribute oil. Replace spark plug.

Follow the lubrication recommendations found in

the Maintenance Section.

Always store the snow thrower in a clean, dry area.

NOTE: When storing any type of power equipment in

an unventilated or metal storage shed, care should be

taken to rust proof the equipment. Using a light oil or

silicone, coat the equipment, especially any chains,

springs, bearings and cables.

19

Loading ...

Loading ...

Loading ...