Loading ...

Loading ...

Loading ...

7

805757 v1.05 06.21 Miniboil Install Instructions

Flow Direction

Pressure

Limiting

Valve

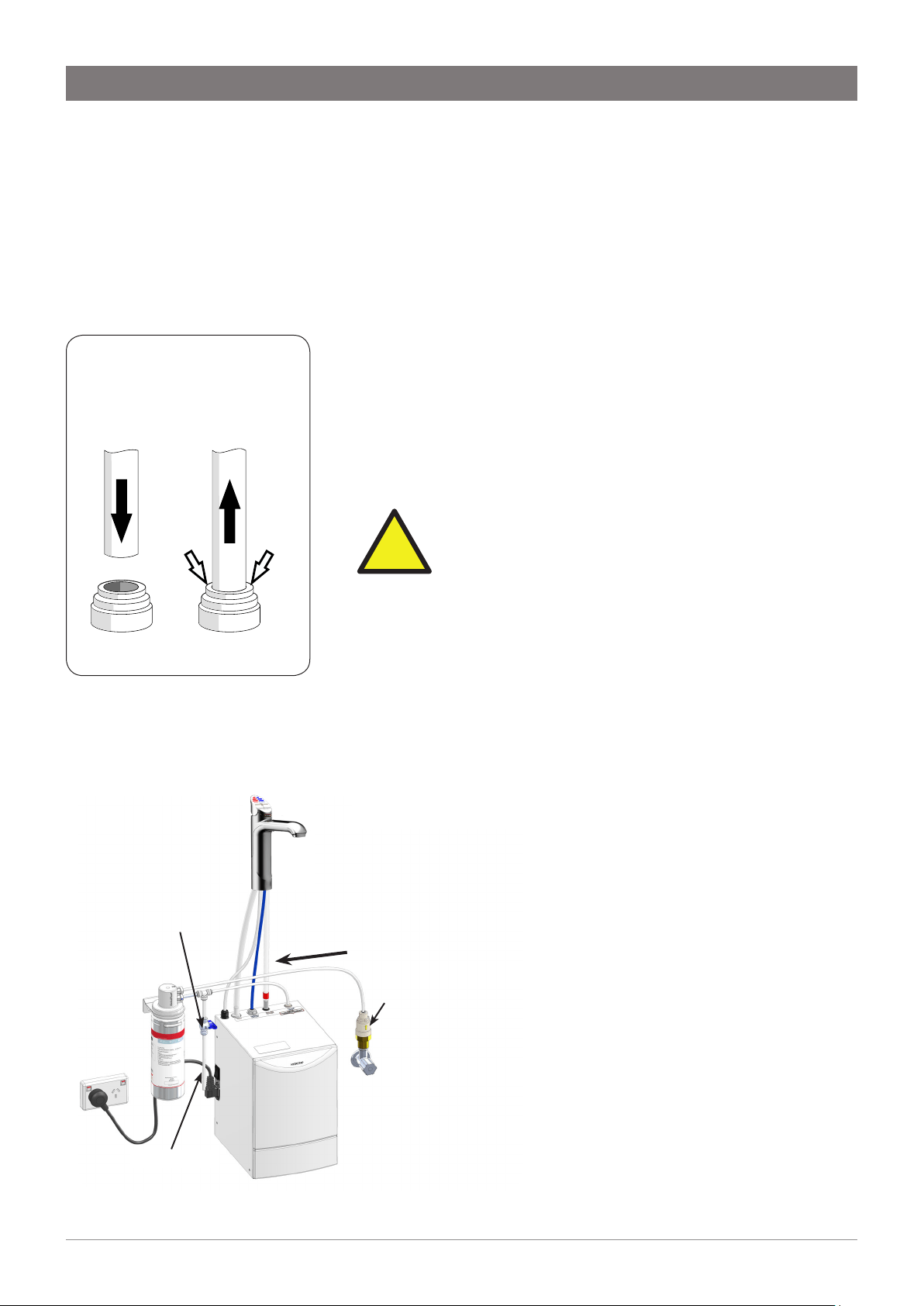

Fig. 2 External Filter Connection

Flush Tube

Flush Valve

Installation

Step B - Installing the filter

Miniboil is supplied with an external filter (see diagram below). It is

important the filter be securely fixed adjacent to the under sink unit in

such a manner as to allow for easy access to the filter, for service and

regular replacement.

The ¼” LDPE tube supplied must be carefully measured and cut to

allow for the connection of the filter, double check valve and JG

fittings.

Step C - Installing the Command Centre

Position the Command Centre as close as possible to the tap.

The connection tubes supplied with the tap assembly CANNOT be

lengthened.

Allow at least a 50 mm air-gap to the RHS for air circulation.

Allow a 70 mm clearance on the LHS of the appliance to ensure the

power lead is free from external force.

IMPORTANT: Proper air circulation and adequate

cupboard ventilation is necessary for efficient

operation.

Adjust cupboard door hinges and attach the supplied silicone

door buffers to create a 4 mm air-gap between the doors and the

cupboard. This is the minimum ventilation requirement for low

usage installations. Failure to do this may cause the appliance to

overheat and operate inefficiently.

Step D - Connecting the water supply

To prevent sediment from the in-wall plumbing entering the

Command Centre at connection, flush water through the supply line

thoroughly before connection.

!

Filter assembly sequence: (see Fig 2)

Fit the pressure limiting valve to the outlet side of the

isolating valve (not supplied).

Mount the filter and flush valve assemblies in a convenient

position using the angle bracket supplied.

Connect the filter assembly plumbing between the

pressure limiting valve and the inlet of the Command

Centre using the ¼” JG fittings supplied (see Fig 1). Take

note of the flow direction, marked with an arrow on the top

of the filter head.

Ensure the flush valve is accessible after installation as this

will be required to flush water through the filter, when the

filter is installed or changed.

Fig 1. John Guest (JG)

fittings - Assembly and

Removal

Loading ...

Loading ...

Loading ...