Loading ...

Loading ...

Loading ...

23

3. Remove pilot and main injectors and replace with correct size injectors as shown in ‘Gas

Specifications Tables’ at end of this section.

4. Refit the following:-

Re-connect pilot supply tube to pilot burner.

Re-connect piezo igniter and thermocouple to mounting bracket.

Refit main burner and secure clamp bracket.

Refit sole plate(s) and lower lintel.

NOTE: There is no 'Low Fire' adjustment on the gas control valve for the GC Oven.

Refit the oven control panel.

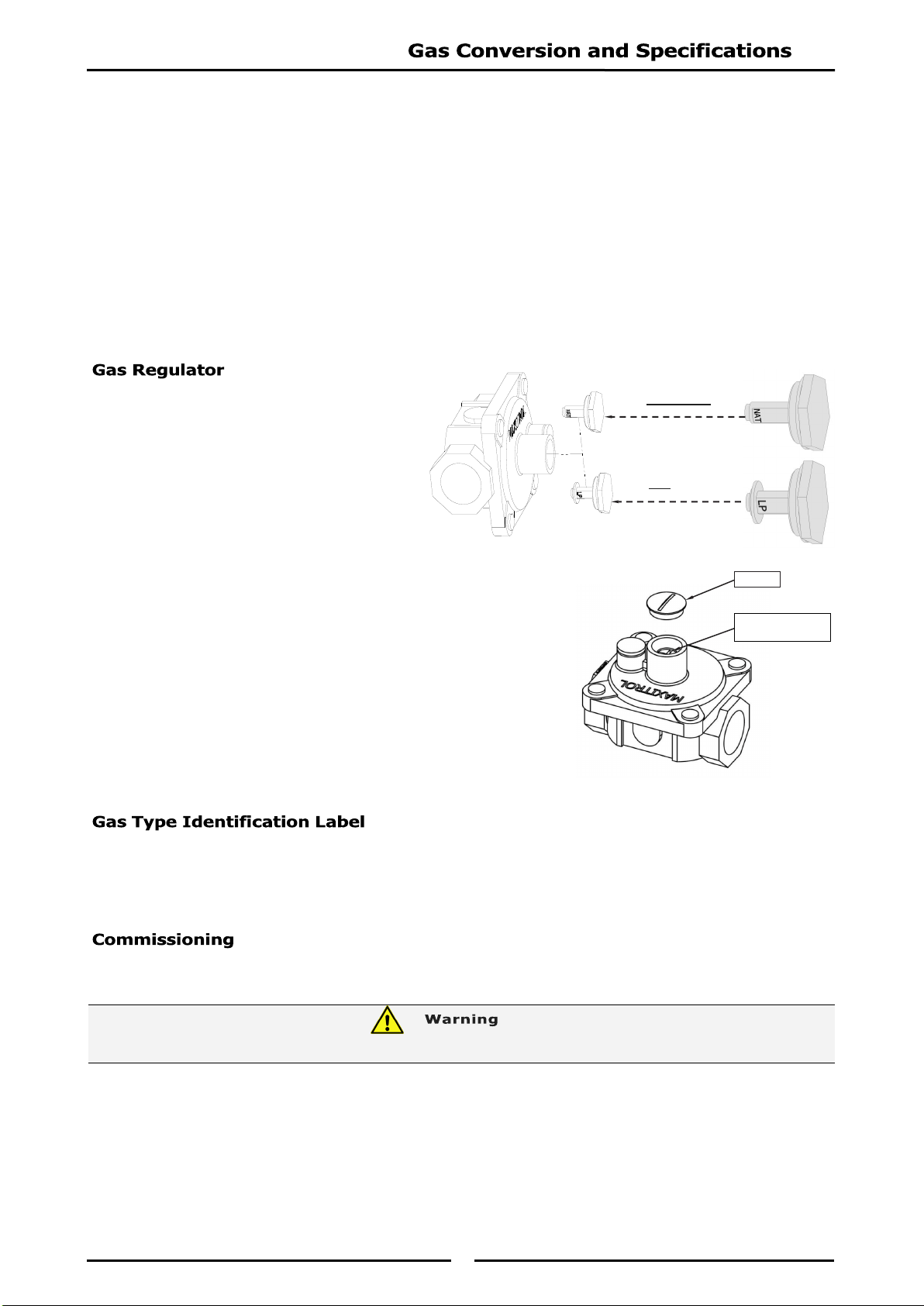

NOTE: Gas regulator supplied is

convertible between Natural

Gas and LP Gas, but it’s outlet

pressure is fixed ex-factory

and is NOT to be adjusted.

- Town Gas Only.

1. Remove slotted cap from regulator.

2. Turn ‘On’ gas supply and appliance.

3. Adjust pressure adjusting screw to achieve correct burner

operating pressure.

NOTE: Measure operating pressure at manifold test point

with two burners operating at 'High Flame' setting.

4. Verify operating pressure remains correct (Re-adjust regulator if

required).

5. Screw cap nut back onto regulator.

On completion of gas conversion, replace gas type identification label located at:-

- Rear of appliance, above gas connection.

- Beside the rating plate.

Before leaving the installation;

1. Check all gas connections for leakage using soapy water or other gas detecting equipment.

2. Carry out a ‘Commissioning’ check of appliance as shown in Installation Section of this manual.

3. Ensure any adjustments done to components that have adjustments / settings paint sealed are to be

re-sealed.

NOTE, Pin rotated

for Natural Gas

NOTE, Pin rotated

for LPG

DO NOT USE A NAKED FLAME TO CHECK FOR GAS LEAKAGES.

Pressure Adjusting

Screw

Cap Nut

Loading ...

Loading ...

Loading ...