Loading ...

Loading ...

Loading ...

Se rvice

5

11

WARNING! Before inspecting, cleaning

or servicing the machine, shut off the

engine, wait for all moving parts to come to

a complete stop, disconnect the spark plug

wire and move the wire away from the

spark plug. Failure to follow these

instructions can result in serious personal

injury or property damage.

Engine

Refer to the Engine Operator’s Manual packed with

your tiller for all engine maintenance.

Tire Pressure

Check the air pressure in both tires. The proper air

pressure is printed on the side of the tires. Keep

both tires equally inflated to help prevent the

machine from pulling to one side.

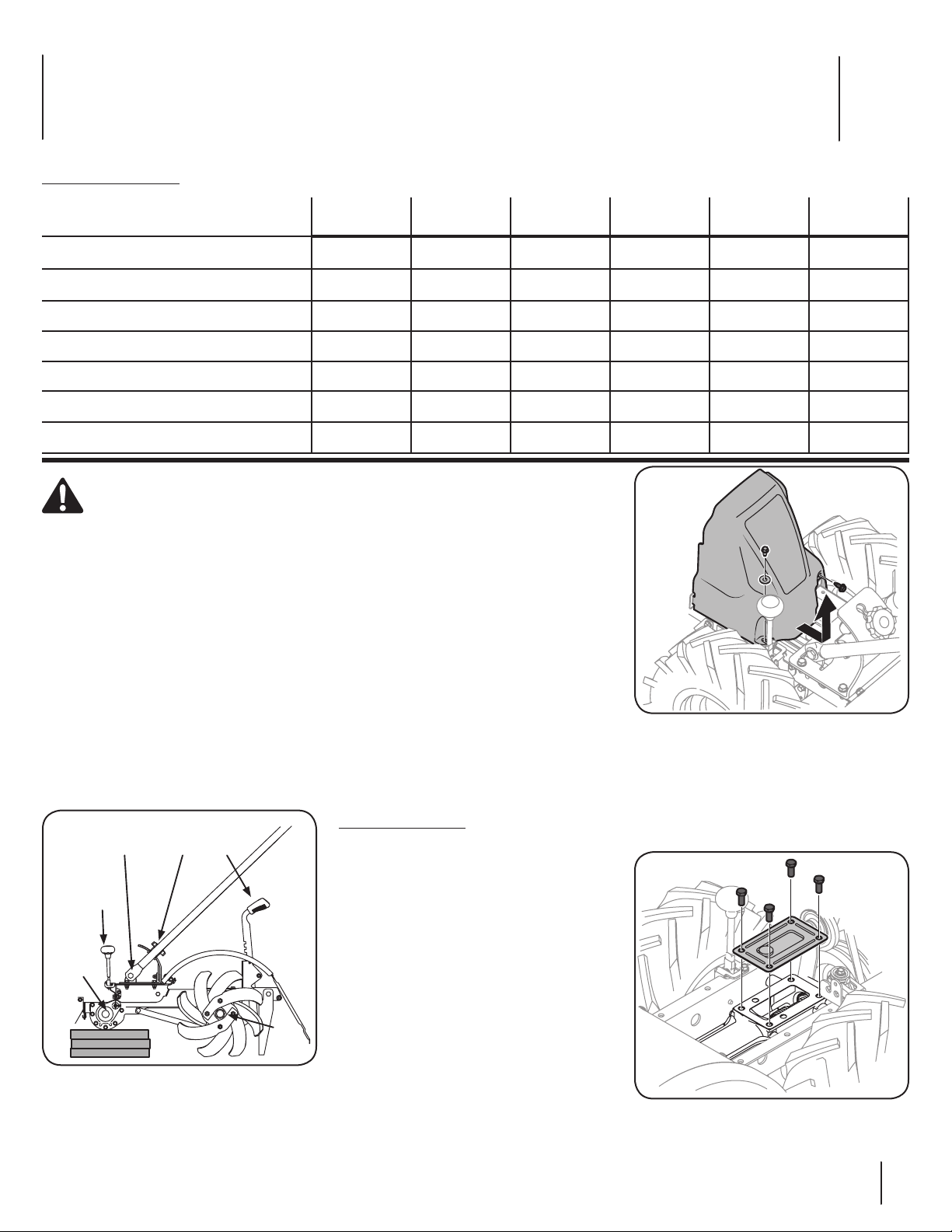

Lubrication

After every 10 operating hours, oil or grease the

lubrication points shown in Figure 5-1.

Handlebar

Attaching

Screws

Depth

Regulator

Lever

Height

Adjust

Knob

Neutral

ENGAGE/

DISENGAGE

Tine

Shaft

Wheel

Shaft

Figure 5-1

Use a clean lubricating oil (#30 weight motor oil is

suitable) and a clean general purpose grease (grease

containing a metal lubricant is preferred).

• Remove the wheels, clean the wheel shaft

and apply a thin coating of grease to the

wheel shaft.

• Grease the back, front and sides of the depth

regulator lever.

• Remove the tines and clean the tine shaft. Use

a file or sandpaper to gently remove any rust,

burrs or rough spots (especially around holes

in the shaft). Apply grease to the ends of the

shaft before installing the tines.

• Oil the threads on the handlebar height

adjustment screws and the handlebar

attaching screws.

Hardware

Check for loose or missing hardware after every 10

operating hours and tighten or replace (as needed)

before using tiller

Be sure to check the screws underneath the tiller

hood that secure the transmission cover and the

Depth Regulator Lever to the transmission.

Transmission Gear Oil

Checking the Transmission Gear Oil

Check the transmission gear oil after every 30 hours

of operation or whenever you notice any oil leak.

Operating the tiller when the transmission is low on

oil can result in severe damage.

1. Check the gear oil level when the

transmission is cool. Gear oil will expand

in warm operating temperatures and this

expansion will provide an incorrect oil level

reading.

2. With the tiller on level ground, pull the Depth

Regulator Lever all the way up.

3. Remove the hex washer screw (⁄-20 x .500)

and flat washer (.28 x .74 x .063) from the

left side of the belt cover and the hex washer

screw (⁄-20 x .500) from the right side of the

belt cover. Remove the belt cover. See Figure 5-2.

Figure 5-2

4. Thoroughly clean the area around the

transmission cover.

5. Remove the four hex screws (⁄-18 x .75)

securing the transmission cover to the drive

shaft and remove the cover. Locate the main

drive shaft below the cover. See Figure 5-3.

Figure 5-3

6. The gear oil level is correct if the gear oil is

approximately halfway up the side of the

main drive shaft.

Maintenance Schedule

Check After

first 2 hours

Before each

use

Every

5 Hours

Every

10 Hours

Every

30 Hours

See Engine

Manual

Check Motor Oil Level

P P

Clean Engine

P P

Lubricate Tiller

P

Check Hardware

P P

Check Gear Oil Level in Transmission

P

Check Tines for Wear

P

Check Air Pressure in Tires

P

Loading ...

Loading ...

Loading ...