Loading ...

Loading ...

Loading ...

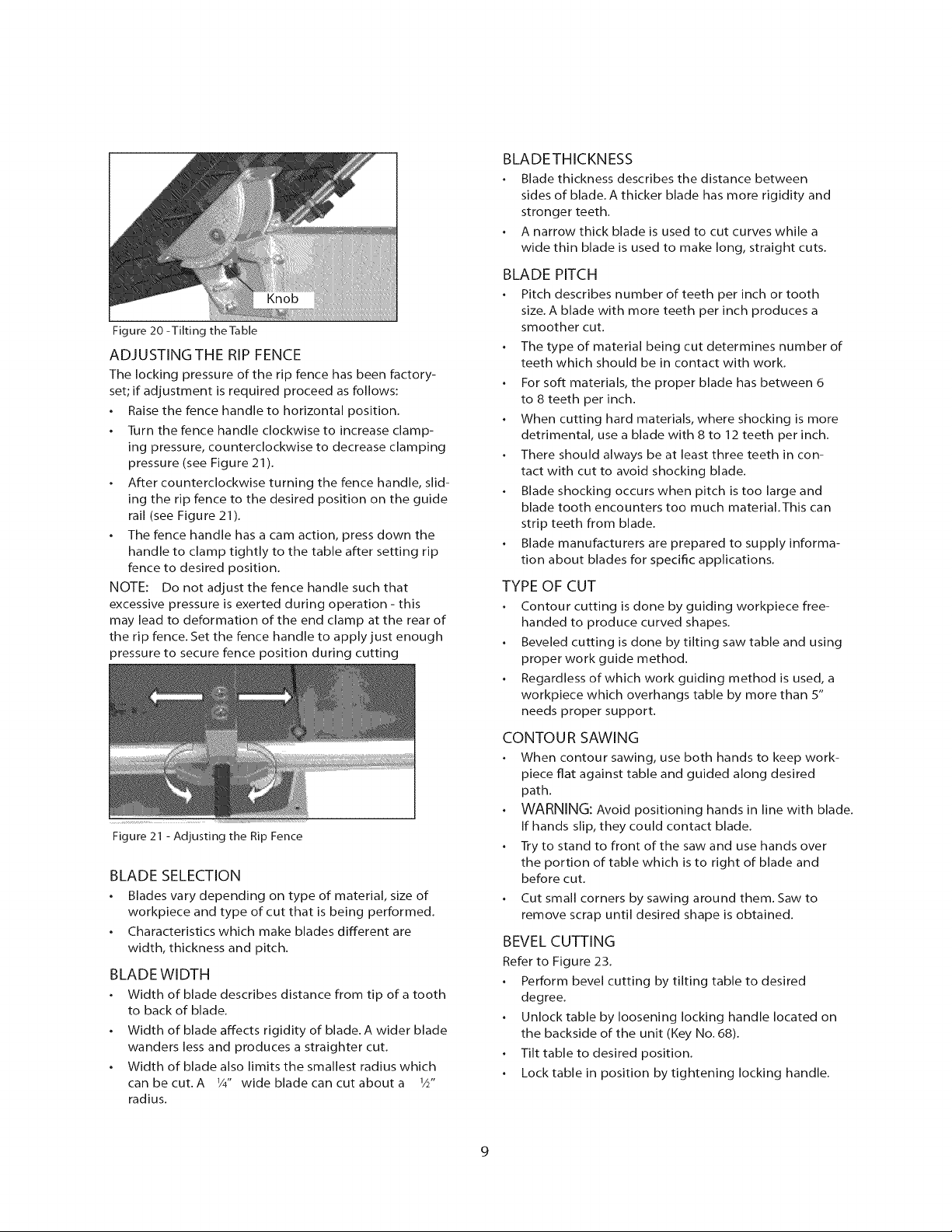

Figure 20 -Tilting theTable

Knob

ADJUSTINGTHE RIP FENCE

The locking pressure of the rip fence has been factory-

set; if adjustment is required proceed as follows:

Raise the fence handle to horizontal position.

Turn the fence handle clockwise to increase clamp-

ing pressure, counterclockwise to decrease clamping

pressure (see Figure 21 ).

After counterclockwise turning the fence handle, slid-

ing the rip fence to the desired position on the guide

rail (see Figure 21).

The fence handle has a cam action, press down the

handle to clamp tightly to the table after setting rip

fence to desired position.

NOTE: Do not adjust the fence handle such that

excessive pressure is exerted during operation - this

may lead to deformation of the end clamp at the rear of

the rip fence. Set the fence handle to apply just enough

pressure to secure fence position during cutting

Figure 21 - Adjusting the Rip Fence

BLADE SELECTION

Blades vary depending on type of material, size of

workpiece and type of cut that is being performed.

Characteristics which make blades different are

width, thickness and pitch.

BLADE WIDTH

Width of blade describes distance from tip of a tooth

to back of blade.

Width of blade affects rigidity of blade. A wider blade

wanders less and produces a straighter cut.

Width of blade also limits the smallest radius which

can be cut. A 1/4" wide blade can cut about a 1A"

radius.

BLADETHICKNESS

Blade thickness describes the distance between

sides of blade. A thicker blade has more rigidity and

stronger teeth.

A narrow thick blade is used to cut curves while a

wide thin blade is used to make long, straight cuts.

BLADE PITCH

Pitch describes number of teeth per inch or tooth

size. A blade with more teeth per inch produces a

smoother cut.

The type of material being cut determines number of

teeth which should be in contact with work.

For soft materials, the proper blade has between 6

to 8 teeth per inch.

When cutting hard materials, where shocking is more

detrimental, use a blade with 8 to 12 teeth per inch.

There should always be at least three teeth in con-

tact with cut to avoid shocking blade.

Blade shocking occurs when pitch is too large and

blade tooth encounters too much material.This can

strip teeth from blade.

Blade manufacturers are prepared to supply informa-

tion about blades for specific applications.

TYPE OF CUT

Contour cutting is done by guiding workpiece free-

handed to produce curved shapes.

Beveled cutting is done by tilting saw table and using

proper work guide method.

Regardless of which work guiding method is used, a

workpiece which overhangs table by more than 5"

needs proper support.

CONTOUR SAWING

When contour sawing, use both hands to keep work-

piece fiat against table and guided along desired

path.

WARNING: Avoid positioning hands in line with blade.

If hands slip, they could contact blade.

Try to stand to front of the saw and use hands over

the portion of table which is to right of blade and

before cut.

Cut small corners by sawing around them. Saw to

remove scrap until desired shape is obtained.

BEVEL CUTTING

Refer to Figure 23.

Perform bevel cutting by tilting table to desired

degree.

Unlock table by loosening locking handle located on

the backside of the unit (Key No. 68).

Tilt table to desired position.

Lock table in position by tightening locking handle.

Loading ...

Loading ...

Loading ...