Loading ...

Loading ...

Loading ...

10

G. BAR AND CHAIN LUBRICANT

J;

• The Guide _ and Cuffing Chain require

continuous lutx-lcl_fonInoi_dertoremain In

operating condition.Lubricationisprovided

,by the automatic oiler sy$-_emwhen the oiltank

is kept filled.

-- L_ckof oilwlll qUlek:lyrutn the bar and chain.

-- Too little oit Willcause overheating shown by

smokecoming fromthe chain and/ordiscolora-

-_mA'rof,theguide bar rails.

• Use Sears 9at and Chain Lubrlcant (#71-36554

- gal. or/f71-36556 - qt.) or clean SAE 30W oil.

• In freezing weather oil will thicken, making

it necessary to thin bar and chain oil withe

small amount of Diesel Fuel #I or

Kerosene. Bar and chain oilmust be free flow-

ing for the oi! system to pump enough oi! for ad-

equ ate lubrication.

1. USETHE FOLLOWING:

3(PFor above -- lubricant-- undiluted.

30o-0°F--95% lubdcant to 5% Dlese! Fuel

: " #1 or Kerosene.

Below0°F--90% lubricant to 10% Diesel

Fuel # 1or Kerosene,

2. HOW TO RLL THE OIL TANK

a. Gtop theengine.

b. "_Jmsaw on its side with oil cap up.

c. Loosencapslowlyandwaitforpressureinthetank

¢obe_eleasedbeforeremovingt,hecap.Figure.12_

d. Fill theoiltank.

e. Replacethe 9ilcap securely.

.

It

i ii i i i ii i i iiii H I m,

ACCESSORIES

3. ADJUSTING THE AUTOMATIC OILER

o

The adjust_bleautomatic Oiler isset for max-

imum output at the factory. Some 1ypes of

cutting will require adjusting the oi|er.

-- less oil is required for soft or freshly cut

wood.

--maximum ol! Is reqmred for hardwood or

wood that has been cut for aperiod of time.

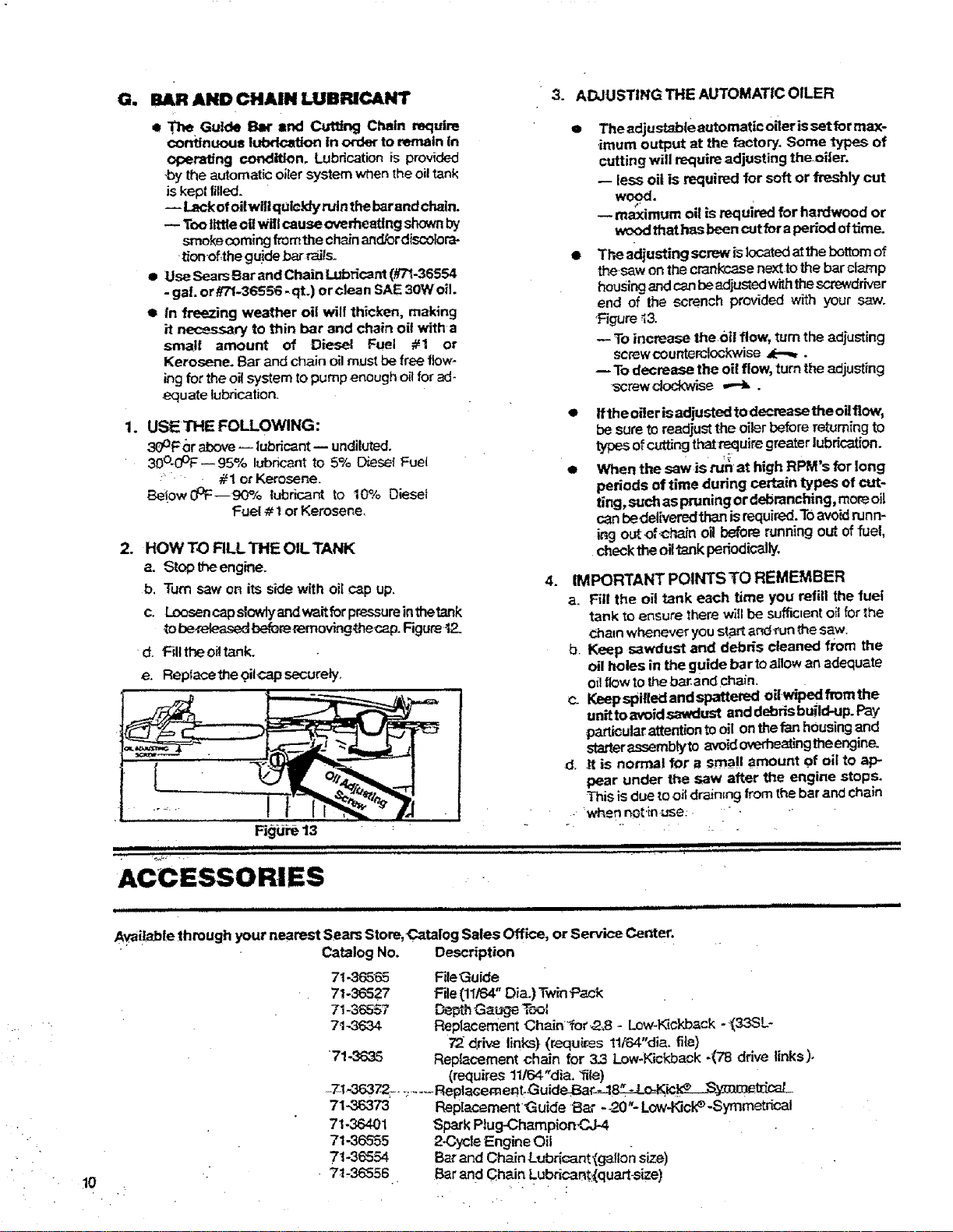

The adjusting screw islocated atthe bottom of

the.saw on the cra_e ne.xtto the bar clamp

houSingand can be adjusted withthe screwdriver

end of the scrench provided with your saw.

_Figure _3.

--To increase the 0il flow, turn the adjusting

screwcountemlockwise _.

-- To decrease the oil flow, turn the adjusting

_crewdockwise _.

ffthe oilerisadjustedtodecmase theoilflOW,

be suretoreadjustthe oilerbefore returning to

typesofcuttingthat_uire greaterlubrication.

When the sew is tun at high RPM's for long

periods oftime during certain types ofcut-

ring,suchas pruningordel:iranching,moreoil

canbedeliveredthan isrequired.TOavoidrunn-

ing outof.chain oUbefore running out offuel,

checkthe oil"_nk periodically.

IMPORTANT POINTS TO REMEMBER

a. Fill the oil tank each time you refill the fuel

tank _oensure there will be suffic|ent oil for the

(:ham whenever you start, end_un _e saw.

b. Keep sawdust and debris cleaned from the

oil holes in the guide barto allow an adequate

Offflow tOthe _ and chin,

C. Keepspilled and spattered oilwiped from the

unit toavoid sm_ust and debris build-up. Pay

patt_ular attention to oil on thefan housing and

starterassemblyto avoid overheating the engine.

d. it is normal for a small amount of oil to ap

pear under the saw after the engine stops.

This is due tooil drain=ngfrom the bar and chain

- when not'in use. " •

A_i!able through your nearest SearsStore, Catalog Sales Office, or Serv'meCenter_

Description

FileGuide

File(11/64" Dia.)TwinPack

D,3pthG_uge Tool,

RePlacement Chain?or _8 - Low-Kickback - _33SL-

72 drive links) (requires 11164"dia.file)

71.3635 Replacementchain for 32 Low-Kickback-(78 drive links)•

(requires 11/64"die. file)

-7....t-36372:..._......Replaeement:Guide._ar--=18"*--J-o-Kic!__

Catalog No.

71-365_

71-36527

71-36557

7_1-,3_34

71-36373

71-36401

71-36555

7t *36554

7,1-36556

ReplacementGuide BB_-- -20"- Low-Kic_ -Symmetrical

Spark Plug-ChampionCJ-4

2-Cycte Engine Oil

Barand Chain Lubricant_gaIIonsize)

Bar and Chain Lubrioant:,(quart-size)

Loading ...

Loading ...

Loading ...