Loading ...

Loading ...

Loading ...

TROUBLE SHOOTING

IF YOUR SAW DOES NOT CUT AS WELl. AS IT SHOULD AFTER SHARPENING OR tT DOES NOT CUT

STRAIGHT, YOU MAY HAVE A WORN OR DAMAGED GUIDE BAR, A WORN SPROCKET, OR DAMAGED

LINKS IN THE CHAIN THIS CAN BE CHECKED AND REPAIRED FOR YOU AT YOUR SEARS SERVICE

DEPARTMENT HOWEVER, BEFORE DOING THIS, CHECK FOR CUTTER PROBLEMS,

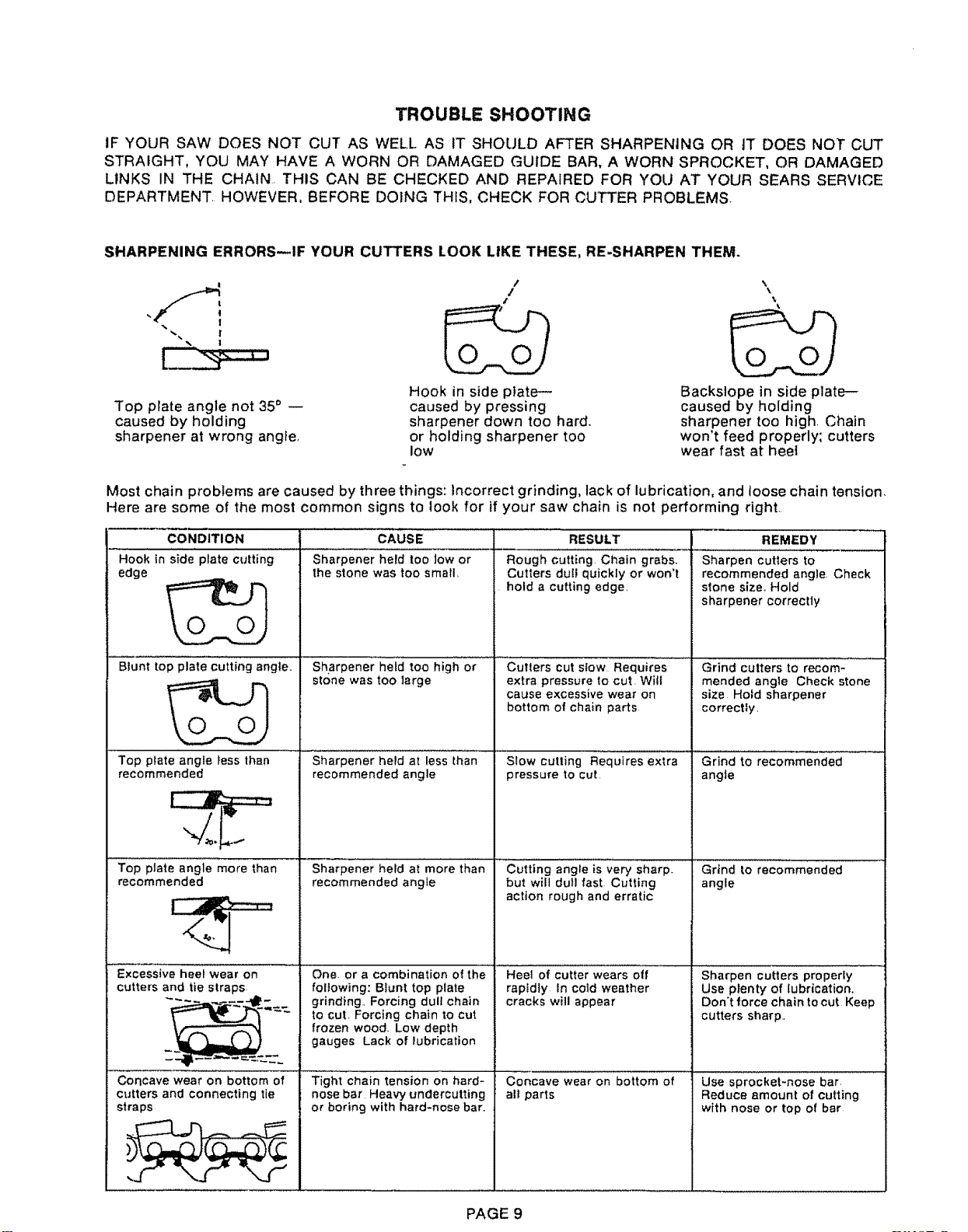

SHARPENING ERRORS_IF YOUR CUTTERS LOOK LIKE THESE, RE-SHARPEN THEM.

Top plate angle not 35 °

caused by holding

sharpener at wrong angle.

/

/

Hook in side plate--

caused by pressing

sharpener down too hard.

or holding sharpener too

low

\

\

\

Backslope in side plate--

caused by holding

sharpener too high Chain

won't feed properly; cutters

wear fast at heel

Most chain problems are caused by three things: Incorrect grinding, lack of lubrication, and loose chain tension.

Here are some of the most common signs to look for if your saw chain is not performing right

CONDITION

Hook in side plate cutting

edge

Blunt top plate cutting angle

Top plate angle less than

recommended

CAUSE

Sharpener held too low or

the stone was too small,

Sharpener hefd too high or

stone was tOO large

..........................J ........................................

Sharpener held at less than

recommended angle

Top plate angle more than Sharpener held at more than

recommended recommended angle

Excessive heel wear on

cutters and tie straps

Concave wear on bottom of

RESULT

Rough cutting Chain grabs.

Cutters dull quickly or won't

hold a cutting edge,

REMEDY

Sharpen cutters to

recommended angle, Check

stone size, Hold

sharpener correctly

Cutters cut slow Requires ...... Grind cutters to recom- ..........

extra pressure to cut Will

cause excessive wear on

bottom of chain parts

Stow cutting Requires extra

pressure to cut

mended angle Check stone

size Hold sharpener

correctly

Grind to recommended ..............................

angle

Cutting angle is very sharp. - Grind to recommended

but will dull fast Cutting

action rough and erratic

One or a combination of the Heel of cutter wears off

following: Blunt top ptate rapidly In cold weather

grinding,, Forcing dull chain cracks will appear

to cut, Forcing chain to cut

frozen wood. Low depth

gauges Lack of lubrication

Tight chain tension on hard-

angle

s,arpen u.ers ProPerlY'

Use plenty of lubrication.

Don't forcechain tocut Keep

cutters sharp

concave wear On bottom Of Use SPr0cket--n0se bar

cutters and connecting tie

straps

nose bar Heavy undercutting

or boring with hard-nose bar.

all parts

Reduce amount of cutting

with nose or top of bar

PAGE 9

Loading ...

Loading ...

Loading ...