Loading ...

Loading ...

Loading ...

FIG. 4

installing Rubber Foot Strip and Wheels

L.........]

It may be necessary to brace or support one

end of the outfit when attaching the wheels

because the air compressor will have a

tendency to tip.

1. Remove the protective paper strip from the adhesive-

backed rubber foot strip. Attach the rubber foot strip to

the bottom of the air tank leg. Press firmly intoplace.

(See page 14 key no. 39.)

_-.The leg bracket on the underside of the air compres-

sor tank has 2 holes on each side for mounting the

wheels. Place one shoulder bolt through the hole in a

wheel. Next, push the bolt through the LOWER hole of

the leg bracket and screw on one hex locking nut. The

special locking nut does not turn freely. Tighten the

nut firmly until it contacts the leg. See pg. 14. The

outfit will set level if the wheels are properly installed.

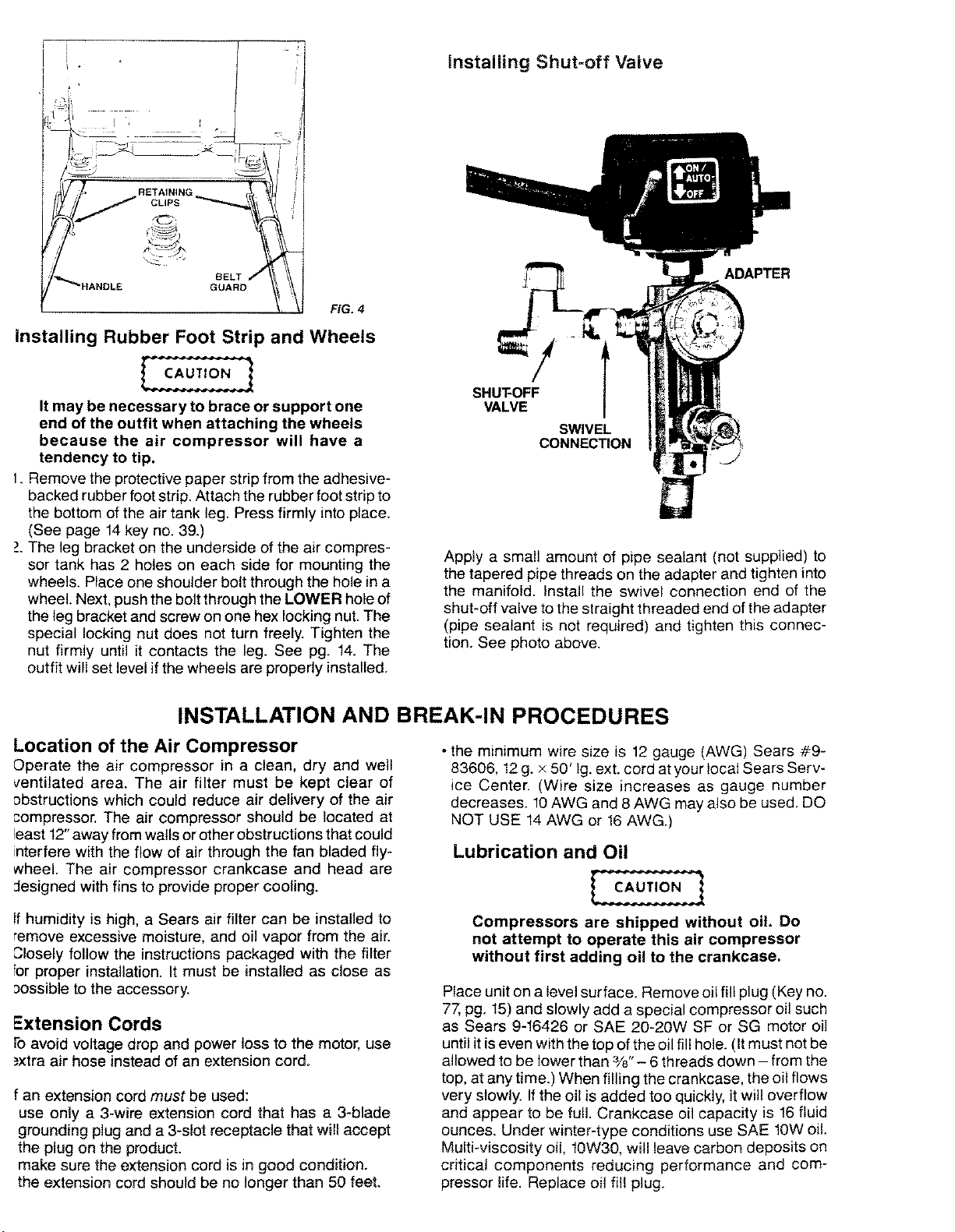

Installing Shut-off Valve

ADAPTER

SHUT-OFF

VALVE

SWIVEL

CONNECTION

Apply a small amount of pipe sealant (not supplied) to

the tapered pipe threads on the adapter and tighten into

the manifold. Install the swivel connection end of the

shut-off valve to the straight threaded end of the adapter

(pipe sealant is not required) and tighten this connec-

tion. See photo above.

INSTALLATION AND BREAK-IN PROCEDURES

Location of the Air Compressor

Operate the air compressor in a clean, dry and well

ventilated area. The air filter must be kept clear of

obstructions which could reduce air delivery of the air

compressor. The air compressor should be located at

least 12" away from walls or other obstructions that could

interfere with the flow of air through the fan bladed fly-

wheel. The air compressor crankcase and head are

3esigned with fins to provide proper cooling.

If humidity is high, a Sears air filter can be installed to

remove excessive moisture, and oil vapor from the air.

Closely follow the instructions packaged with the filter

Forproper installation, it must be installed as close as

oossible to the accessory.

Extension Cords

Foavoid voltage drop and power loss to the motor, use

._xtraair hose instead of an extension cord.

f an extension cord must be used:

use only a 3-wire extension cord that has a 3-blade

grounding plug and a 3-slot receptacle that will accept

the plug on the product.

make sure the extension cord is in good condition.

the extension cord should be no longer than 50 feet.

- the minimum wire size is 12 gauge (AWG) Sears #9-

83606, 12 g. x 50' tg. ext. cord at your local Sears Serv-

ice Center. (Wire size increases as gauge number

decreases. 10 AWG and 8 AWG may also be used. DO

NOT USE 14 AWG or 16 AWG.)

Lubrication and Oil

Compressors are shipped without oil. Do

not attempt to operate this air compressor

without first adding oil to the crankcase,

Place unit on a level surface. Remove oil fill plug (Key no.

77, pg. 15) and slowly add a special compressor oil such

as Sears 9-16426 or SAE 20-20W SF or SG motor oil

until it is even with the top of the oil fill hole. (It must not be

allowed to be lower than %"- 6 threads down - from the

top, at any time.) When filling the crankcase, the oil flows

very slowly. If the oil is added too quickly, it will overflow

and appear to be full. Crankcase oil capacity is !6 fluid

ounces. Under winter-type conditions use SAE 10W oil.

Multi-viscosity oil, 10W30, will leave carbon deposits on

critical components reducing performance and com-

pressor life. Replace oil fill plug.

Loading ...

Loading ...

Loading ...