Loading ...

Loading ...

Loading ...

ACCESSORIES FOR USE WITH SEARS AIR COMPRESSORS

Tile following accessories are available through the current general sales catalog or at full-line Sears stores.

*SPRAY GUNS

.BLOW GUNS

-AIR CAULKING GUNS

,AIR POWERED WASHER GUNS

-SAND BLASTERS

,AIR BRUSHES

-AIR LINE FILTERS

*TIRE AIR CHUCKS

-PAINT TANKS

*AIR TANKS

*INFLATOR KITS

.QUICK CONNECTOR SETS

(various sizes)

oVISCOSIMETER

*AIR PRESSURE REGULATORS

*OIL FOG LUBRICATORS

*AIR TOOLS:

Sanders

Drills

Impact wrenches

Hammers

,AIR HOSE:

1/4", 5/16" OR 3/8" LD.

in various lengths.

GENERAL INFORMATION

_'ouhave purchased an air compressor unit consisting of

a 2 cylinder, single stage air compressor pump, an air

:ank, air hose, wheels, handle, air chuck and associated

:ontrols and instruments.

Your air compressor can be used for operating paint

spray guns, air tools, caulking guns, grease guns, air

3rushes, sandblasters, power washers, inflating tires

and plastic toys, spraying weed killers, insecticides, etc.

for removal of moisture and oil vapor in compressed air

when a paint spray gun is used.

An in-line lubricator is usually required for air tools to

prolong toot life.

Separate air transformers which combine the functions

of air regulation and/or moisture and dirt removal should

be used where applicable.

Fhis model is not equipped with a pressure regulator. An

_ir pressure regulator is usually necessary for most of

:hese applications. An Air Line Filter is usually required

These accessories can be purchased from most Sears

stores or through the Sears General catalog or Power

Tool catalog.

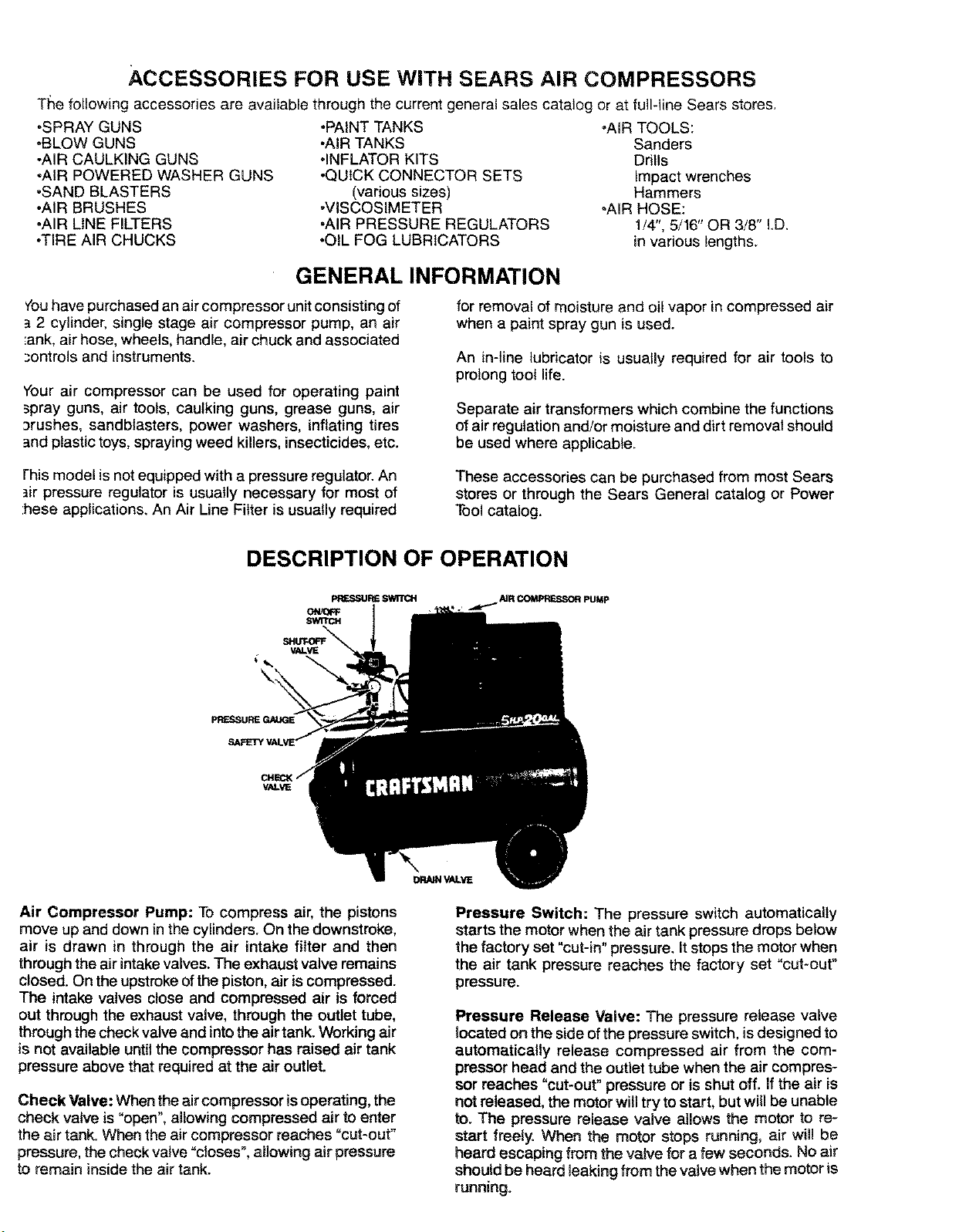

DESCRIPTION OF OPERATION

\

V/eVE

Air Compressor Pump: To compress air, the pistons

move up and down in the cylinders. On the downstroke,

air is drawn in through the air intake filter and then

through the air intake valves. The exhaust valve remains

closed. On the upstroke of the piston, air is compressed.

The intake valves close and compressed air is forced

out through the exhaust valve, through the outlet tube,

through the check valve and into the air tank. Working air

is not available until the compressor has raised air tank

pressure above that required at the air outlet.

Check Valve: When the air compressor isoperating, the

check valve is "open", allowing compressed air to enter

the air tank. When the air compressor reaches "cut-out"

pressure, the check valve "c!oses", allowing air pressure

to remain inside the air tank.

Pressure Switch: The pressure switch automatically

starts the motor when the air tank pressure drops below

the factory set "cut-in" pressure. It stops the motorwhen

the air tank pressure reaches the factory set "cut-out"

pressure.

Pressure Release Valve: The pressure release valve

located on the side ofthe pressure switch, is designed to

automatically release compressed air from the com-

pressor head and the outlet tube when the air compres-

sor reaches "cut-out" pressure or is shut off. If the air is

not released, the motor willtry to start, but wil be unable

to. The pressure release valve allows the motor to re-

start freely. When the motor stops running, air will be

heard escaping from the valve for a few seconds. No air

should be heard leaking from the valve when the motor is

running.

Loading ...

Loading ...

Loading ...