Loading ...

Loading ...

Loading ...

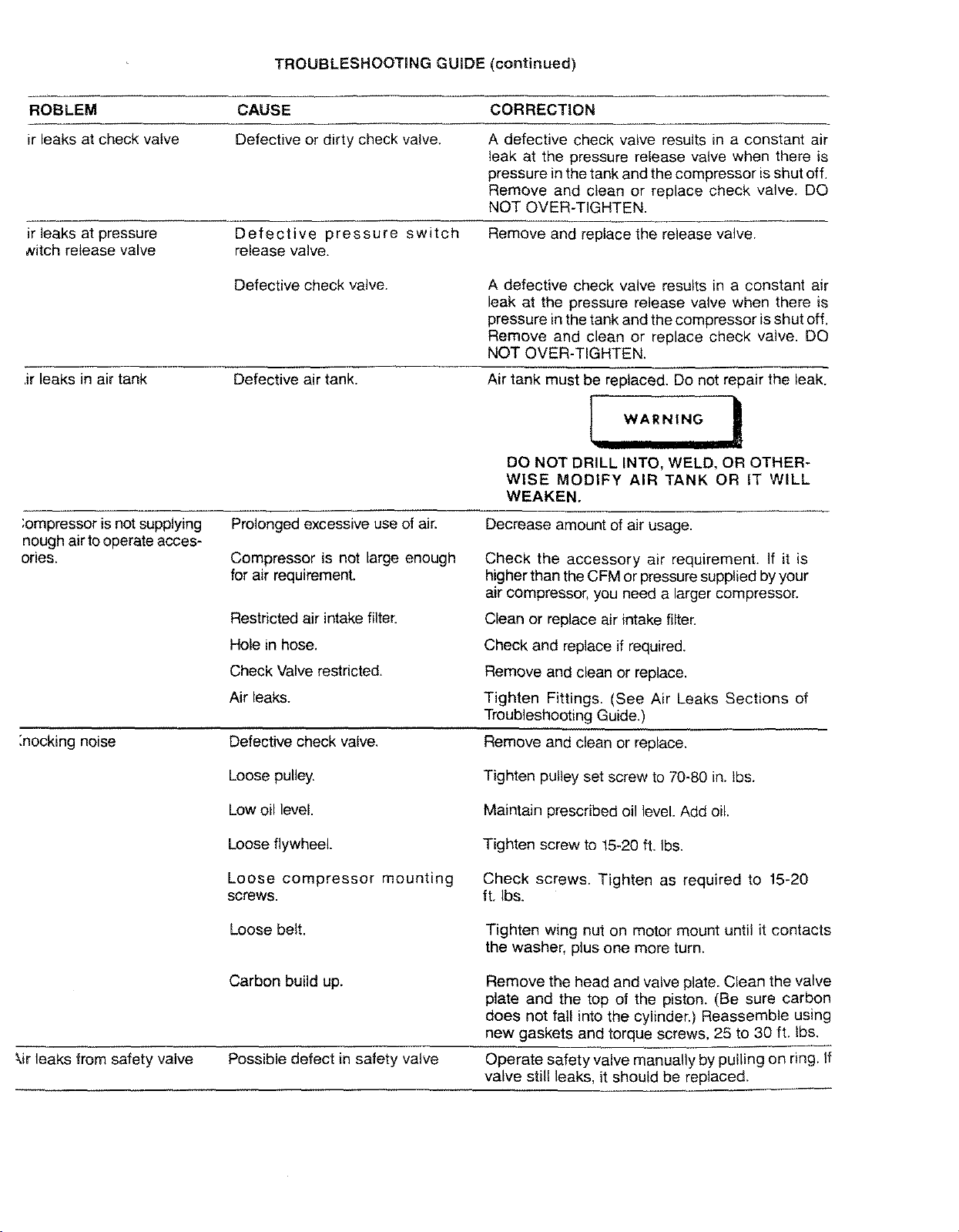

TROUBLESHOOTING GUIDE (continued)

ROBLEM CAUSE CORRECTION

ir leaks at check valve Defective or dirty check valve. A defective check valve results in a constant air

leak at the pressure release valve when there is

pressure in the tank and the compressor is shut off.

Remove and clean or replace check valve. DO

NOT OVER-TIGHTEN.

ir leaks at pressure Defective pressure switch Remove and replace the release valve.

,vitch release valve release valve.

Defective check valve. A defective check valve results in a constant air

leak at the pressure release valve when there is

pressure in the tank and the compressor is shut off.

Remove and clean or replace check valve, DO

NOT OVER-TIGHTEN.

,ir leaks in air tank Defective air tank.

Air tank must be replaced. Do not repair the leak.

, WARNING

DO NOT DRILL INTO, WELD, OR OTHER-

WISE MODIFY AIR TANK OR IT WILL

WEAKEN.

;ompressor is not supplying

nough air to operate acces-

cries.

:nocking noise

Prolonged excessive use of air. Decrease amount of air usage.

Compressor is not large enough

for air requirement.

Restricted air intake filter.

Hole in hose.

Check Valve restricted.

Air leaks.

Defective check valve.

Check the accessory air requirement. If it is

higher than the CFM or pressure supplied by your

air compressor, you need a larger compressor.

Clean or replace air intake filter.

Check and replace if required.

Remove and clean or replace.

Tighten Fittings. (See Air Leaks Sections of

Troubleshooting Guide.)

Remove and clean or replace,

Loose pulley.

Tighten pulley set screw to 70-80 in. tbs.

Low oil level.

Maintain prescribed oil level, Add oil.

Loose flywheel. Tighten screw to 15-20 ft. Ibs.

Loose compressor mounting

screws.

Check screws. Tighten as required to 15-20

ft. Ibs.

Loose belt.

Tighten wing nut on motor mount until it contacts

the washer, plus one more turn.

Carbon build up. Remove the head and valve plate. Clean the valve

plate and the top of the piston. (Be sure carbon

does not fall into the cylinder.) Reassemble using

new gaskets and torque screws, 25 to 30 ft. Ibs,

kit leaks from safety valve Possible defect in safety valve Operate safety valve manually by pulling on ring. If

valve still leaks, it should be replaced.

Loading ...

Loading ...

Loading ...