Loading ...

Loading ...

Loading ...

5

www.napoleongrills.com

EN

Built In Natural Gas Hook-Up: The piping up to the gas grill is the responsibility of the installer and piping

should be located as shown in the built-in instrucons. Do not use hose to connect the unit. It must be

connected with rigid pipe, copper tube or an approved exible metal connector. The installaon must

comply with CAN B149.1 Natural Gas and Propane Installaon Code in Canada, or to the Naonal Fuel

Gas Code, ANSI Z223.1 in the United States. The minimum recommended piping size is NPS 1/2” for

rigid pipe, and 5/8” OD for copper tubing (based on a 20 run). Longer runs may require larger sizes

to conform with local codes or to conform with CAN B149.1. Natural Gas Installaon Code in Canada or

to the Naonal Fuel Gas Code, ANSI Z223.1 in the United States. A exible metal connector is included

to simplify the installaon of the unit. Connect this connector to the 3/8” are ng on the end of the

manifold. Connect the other end of the connector to the gas piping. Ensure that the connector does not

pass through a wall, oor, ceiling or paron, and is protected from damage. For the BISZ300, the gas

supply must be connected to the 3/8” are elbow ng located under the right hand side of the control

panel. For the BISB245, the gas supply must be connected to the 3/8” are ng located on the inlet side

of the included regulator. The included regulator must be used with the appliance.

IMPORTANT! Built in units are supplied with a drip pan which holds only a minimal amount of

grease. To prevent grease res, the pan must be cleaned aer each use.

Leak Tesng Instrucons

WARNING! A leak test must be performed annually and each me a cylinder is hooked up or if a

part of the gas system is replaced.

WARNING! Never use an open ame to check for gas leaks. Be certain no sparks or open ames

are in the area while you check for leaks. Sparks or open ames will result in a re or explosion,

damage to property, serious bodily injury, or death.

Leak tesng: This must be done before inial use, annually, and whenever any gas components are

replaced or serviced. Do not smoke while performing this test, and remove all sources of ignion. See Leak

Tesng Diagram for areas to check. Turn all burner controls to the o posion. Turn gas supply valve on.

Brush a half-and-half soluon of liquid soap and water onto all joints and connecons of the regulator,

hose, manifolds and valves.

Bubbles will indicate a gas leak. Either ghten the loose joint or have the part replaced with one

recommended by the Napoleon Customer Soluons department and have the grill inspected by a cered

gas installer.

If the leak cannot be stopped, immediately shut o the gas supply, disconnect it, and have the grill

inspected by a cered gas installer or dealer. Do not use the grill unl the leak has

been corrected.

STOP

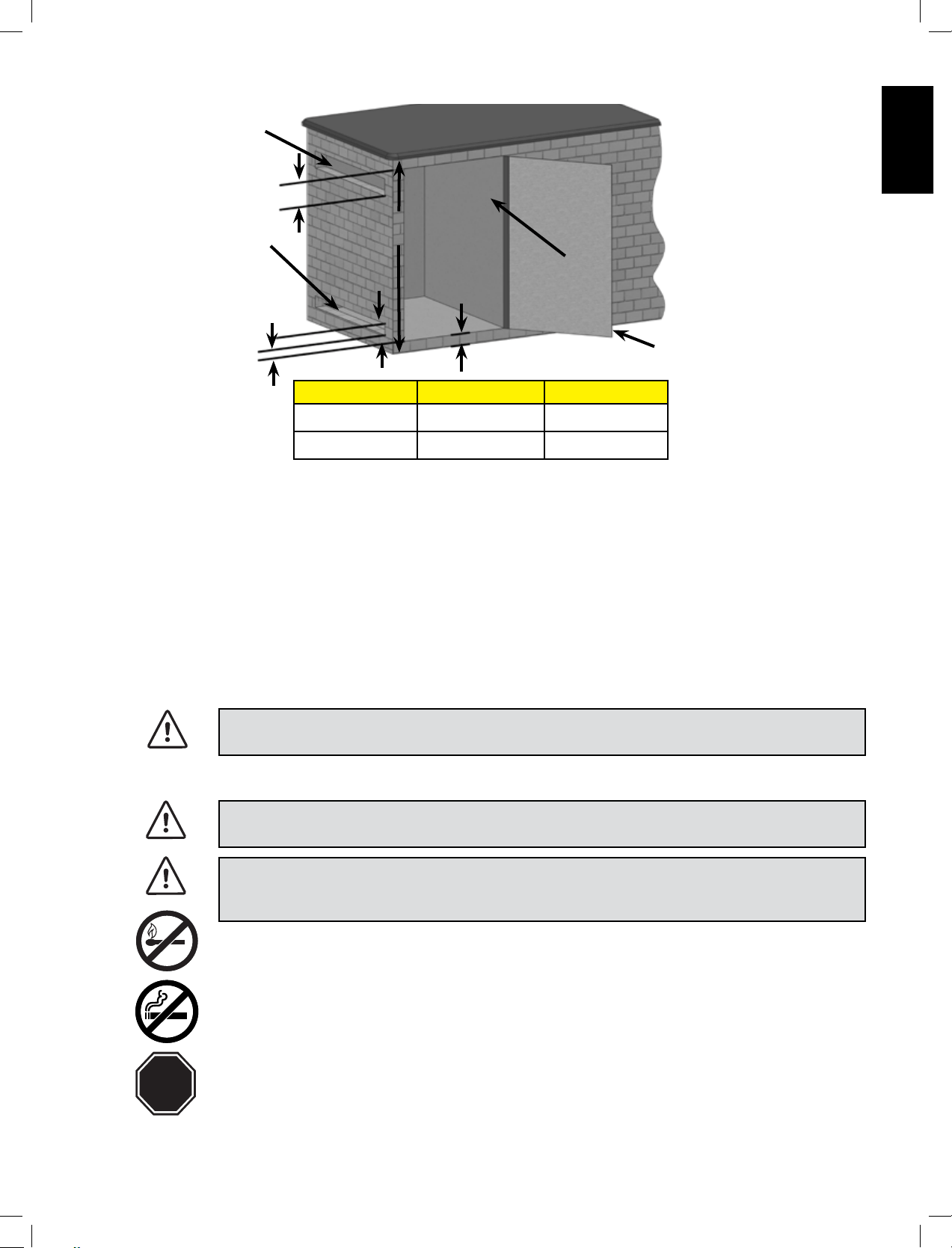

CYLINDER SIZE OPENING A AREA OPENING B AREA

20 lb (9.1 kg)

20 in

2

(130 cm

2

) 10 in

2

(65 cm

2

)

30 lb (13.6 kg)

30 in

2

(195 cm

2

) 15 in

2

(100 cm

2

)

5” (127 mm)

MAXIMUM

1” (25.4 mm)

MAXIMUM

OPENING

A

OPENING

B

2” (51 mm)

MINIMUM

PARTITION TO ISOLATE

CYLINDER FROM GRILL

NON LOCKING DOOR

34” (864 mm)

RECOMMENDED

5” (127 mm)

MAXIMUM

Propane Enclosure

Loading ...

Loading ...

Loading ...