Loading ...

Loading ...

Loading ...

__ i i ii iii i i

__ i iiiff ,L III I I

D. CJLRBURETOR ADJUSTMENTS

• Poorengineperformancecanbe_zmsultotother

causes such as dirtyair filter,caH_onbuild-up on

muffler outlets, etc. See "Trouble Shooting

Chart" before proceeding with carburetor

adjustments.

• For best results, Poulan recommends that you

have a qualified service dealer make all car-

buretor adjustments. Yourdealerhasthe training,

experience and toolsnecessaryto properly adjust

yoursaw tomeet ourfactoryperformancespecifica-

tions. This service is not coveredby.warrant, if it

becomes necessary for you to make carburetor

adjustmentsyourself,followthe procedures below

veryc_refully.

• Thocarburetorhasbeenadjustedatthefactoryforsea

levelcondit_ons.Adjustmentsmaybecomenecessary

ifthesaw isusedatsignificantlyhigheraltitudesor if

younoticeany oflhe following conditions:

NOTE: Be sure to propedy prepare the saw as

describedin"1. Preparation" below,before making

any adjustments.

Chain moves when the engine runs at idle

speed. See "2, Idle Speed Adjustment:'

-- Saw will not idle. See "2, Idle Speed Adjust°

roent" and "3. Low Speed Mixture Adjust-

ment."

Enginediesor hesitates when itshould accel-

erate. See "4, Acceleration Adjustment."

-- Loss of cutting power whlch is not corrected

byairfiltercleaning. "See"5. High Speed Mix-

ture Adjustment."

[CAUTION:I Permanent damage willoccurto any

2-cycle engine if incorrect carburetor adjust-

ments are rnade.

ifthe unit w'dlnot operate prol_edyafter making

these adjustroents,take the sawton qualified ser-

vice dealer.

t AWAR"iNG i

The chain will be moving during most of this pro-

cedure. Wear your protective gear and observe all

safety precautions.

i. PREPARATION

a. Stop engine.

b. Use a fresh fuel mixture with proper gasoline/

oil ratio.

c. Placethesawonasclid,flatsurfaceand roakesure

the chainwilinotcontactany object.

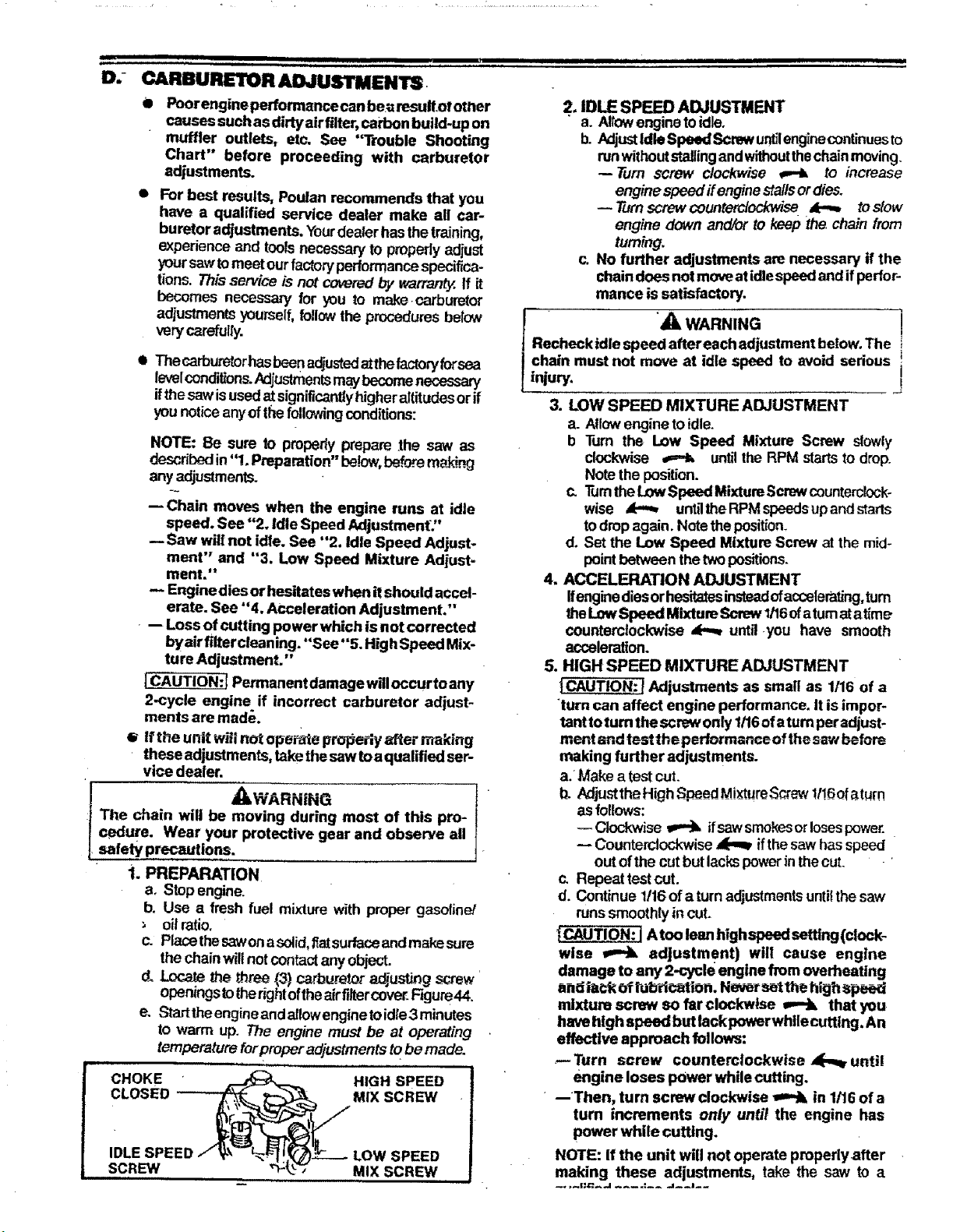

d. Loca_ the three (3) c_'buretor adjusting screw

openingstothedghtofthe airfittercover.Figure44.

e. Startthe engine and allowengine toidle 3 minutes

to warm up. The engine must be at operating

temperature forproper adjustments to be made.

CHOKE _ _ HIGH SPEED

CLOSED __ Mix SCREW

IDLE SPEED __,._ _- LOW SPEED

SCREW _'_':%' MIX SCREW

ii i ii i| ii

2, IDLE SPEED ADJUSTMENT

• a. Altowenginetoidle.

b. AdjustIdta Speed Screwuntilenginecontinues to

runwithoutstallingand withoutthechain.moving.

--Turn screw clockwise _ to increase

engine spe_l ff enginestatlsordies.

-- Turnscrewcounterc/ockwise_ toslow

engine down and!orto keep the chain from

turning.

c. No further adjustments are necessary if the

chaindoes notmoveat idlespeedand ifperfor-

mance iS satisfactory.

I ,t_ WARNING

Recheck idlespeed aftereach adjustment below. The

I chain must not move at idle speed to avoid sedous

injury.

3. LOW SPEED MIXTURE ADJUSTMENT

a. Allowengine toidle.

b Turn the Low Speed Mixture Screw slowly

clockwise _ untilthe RPM starts to drop.

Note the position.

c. TurntheLowSpeed Mixture Screwcounterclock-

wise _ untiltheRPM speedsup andstads

todropagain. Notetheposltion_

d. Set the Low Speed Mixture Screw at the mid-

pointbetween thetwo positions.

4. ACCELERATION ADJUSTMENT

Ifeeginediesorhesitatesinsteadofacceleraling,turo

theLow Speed Mixture Screw1/16ofaturnatatim_

counterclockwise _ until you have smooth

acceleration.

5. HIGH SPEED MIXTURE ADJUSTMENT

|CAUTION: ! Adjustments as small as 1/16 of a

"turncan affect engine performance. It is impor-

tantto turnthe screw only1/16ofaturn peradjust-

ment and test the performanceof thesaw before

making further adjustments.

a. Make a test cut.

b. hz_ustth_HighSp_edMixtumS_ew !1!6of a_tu[n

aSfollows:

Clockwise _ ifsawsmokesorlosespower.

-- Counterclockwise_ ifthesaw hasspeed

out ofthe cutbutlackspower in the cut,

c. Repeat test cut.

d. Continue 1/16of a turn adjustments until the saw

runs smoothly in cut.

_-CAUT!ON: JAtoo lean highspeed setting(clock-

wise _ adjustment) wil! cause engine

damage to any 2-cycle engine from overheating

ahcilack of ta"b_ca't'_n. N_tsetthehlgh sp_i

roixtum screw so far clockwise _ that you

have high speed but tackpowerwhile cutting, An

effective approach follows:

.--Turn screw counterclockwise _ unti!

engine loses power while cutting.

• --Then, turn screw clockwise _ in 1/16of a

turn increments only until the engine has

power while cuffing.

NOTE: If the unit will not operate properly.after

making these adjustments, take the saw to a

Loading ...

Loading ...

Loading ...