Loading ...

Loading ...

Loading ...

I I 111 I" - -IIIIIIIIII - _ , E _ I IIII iii jiiiijiiiiiiiiiiii I I I IIIIIIIIIIIIIII

........................... , i _ ,_ ............ ill ...... i i l i,

MAINTENANCE

................................... I

A good maintenance program of regular inspec-

tion and care will increase the service life and

help to maintain lhe safety and performance of

your saw,

• Make all adjustments or repairs (except car. "

buretor adjustments) with:

--spark plug wire disconnected

-- engine coolas opposedto a saw that has just

been run,

i[ i, L, I ,,

_ iiiiiiiii iiiii iiiiiii i i i I I I

A. GUIDE BAR AND CHAIN

Increase the service life of your Guide Bar and

Chain by:

.-; Using the saw properly and as recommended in

this manual.

Maintaining correct Chain Tension, page 8.

-- PrOper lubrication, page 10.

--Regular maintenance as described in this

section.

1, CHAIN MAINTENANCE

• Sharpen the chain when:

wood chips are small and powdery. Wood

=chipsmade bythe sawchain shouldbe about

the size of the teeth of the chain.

--saw has to be forced through the cut.

-_saw cuts tO one side.

{CAUTION: IAIways wear gloves when handling the

chain. The chain can be sharp enough to cut you even

though it;is 'too dull to cut wood.

a. SHARPENING INSTRUCTIONS

Items required:

Gloves Rat File

5/32" Dia.file Depth Gauge Tool

6" Fileholder

1,) Stop engine.

2.) Adjust the chain for proper tension; page 8.

3.) Work at the midpoint of the bar, movingthe

chain forward byhandas each cutter isfiled.

4.) Sharpen cuttem.

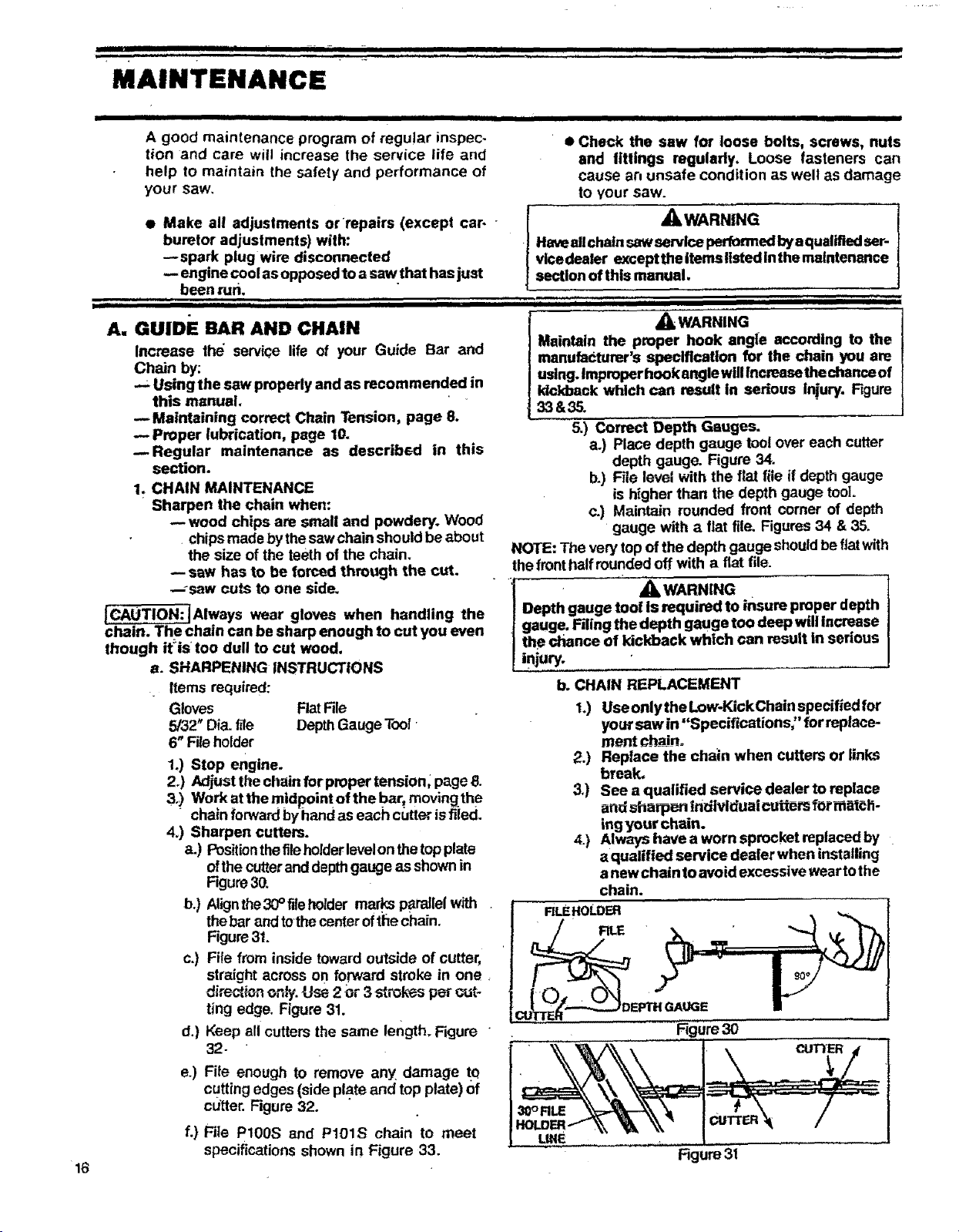

a.) Positionthefileholderlevelon thetop plate

ofthe cutterand depthgauge as shownin

Figure30.

b.) Alignthe30° fileholder marks paraJIeiwith +

thebar and totho centerofthechain.

Figure31.

c.) File from inside toward outside of cutter,

straight across on forward stroke in one +

d_re_ c.'_f. Use 2 _,r3 strokes pe_ cut-

ting edge. Figure 31.

d.) Keep all cutters the same length. Figure

32.

e.) Fiie enough to remove any, damage tO

cutting edges (side plate and top plate) of

critter. Figure 32.

f.) File P100S and PI01S chain to meet

specifications shown in Figure 33.

16

I IIIIII

' • Check the saw for loose bolts, screws, nuts

and tittings regulady, Loose fasteners can

cause an unsafe condition as well as damage

to your saw.

_I_WARNING

Haveailchaln sawservlce performedbyaquallfied ser-

vicedealer exceptthe items listedinthe maintenance

section of this manual.

II I II IIII I lil l I il " I II IIIIII ' ' II"

,_WARNING

Maintain the proper hook angle according to the

manufacturer's speclfleatton for the chain you am

using.Improper hook anglewill lncreasethe chance of

kickback which can result In serious Injury. Rgure

33&35.

5.) Correct Depth Gauges.

a.) Place depth gauge tool over each cutter

depth gauge. Figure 34.

b.) File level with the flat file if depth gauge

is higher than the depth gauge tool.

c.) Maintain rounded front comer of depth

gauge with a flat file. Figures 34 & 35+

NOTE: The verytop of the depth gauge shouldbefiat with

thefronthalf rounded off with a fiat file.

'l &WARNING +

| Depth gauge tool is required to insure proper depth

gauge. Filing the depth gauge too deep will increase

i the chance of kickback which can result in serious

!l,jury.

b. CHAIN REPLACEMENT

1.) Use only the Low-KickChain specified for

your saw in "Specifications;' for replace-

ment ch_.-

2.) Replace the chain when cutters or links

break,

3.) See a qualified service dealer to replace

and sharpen iridividuai_utte_ for ttl_tteli-

ing your chain.

4.) Always have a worn sprocket replaced by

aqualified service dealer when installing

anew chain to avoid excessive weartothe

chain.

FILEHOLDER

I_LE

+

[GAUGE i

Figure 30

CUTTER

Figure31

Loading ...

Loading ...

Loading ...