Loading ...

Loading ...

Loading ...

CAUTION

• Install the indoor unit leveled.

If the indoor unit is inclined and the drain piping side gets

high,itmaycausemalfunctionofoatswitchandresultin

water leakage.

• Attach nuts on the upper and lower side of hanger.

If there is no upper nut and the lower nut is over-tightened,

the hanger and the top plate will deform and cause abnormal

sound.

• Donotinsertmaterialsotherthanthatspeciedinto

the clearance between the hanger and the washer for

hanger bracket (11).

Unless the washers are properly attached, the

suspension bolts may come off from the hanger.

WARNING

The indoor unit must be securely installed on a place

that can withstand the mass.

Ifthestrengthisinsufcient,theindoorunitmayfalldown

and cause injuries.

6. REFRIGERANT PIPING WORK

Refer to the installation manual for the outdoor unit also.

• Carry out insulation of both gas and liquid refrigerant piping

securely. If not insulated, it may cause water leakage. For

gas piping, use insulation material of which heat resistant

temperature is not less than 230°F (110°C).

For use under high humidity, strengthen the insulation

material for refrigerant piping. If not strengthened, the

surface of insulation material may sweat.

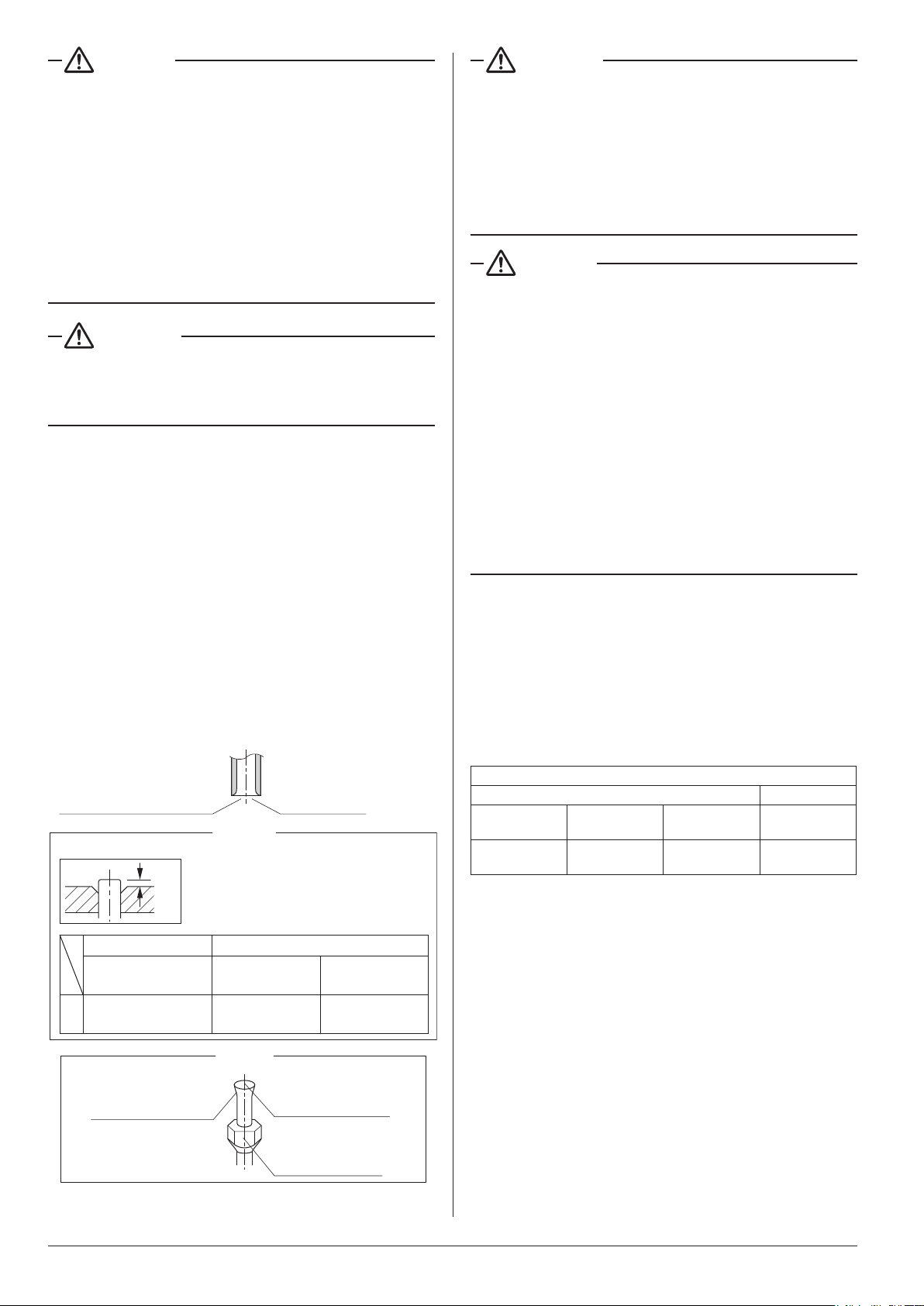

(1) Flaring the pipe end

1. Cut the pipe end with a pipe cutter.

2. Remove burrs with the cut surface facing downward,

sothatthelingsdonotenterthepipe.

3.Putthearenutonthepipe.

4. Flare the pipe.

5.Checkthatthearinghasbeendonecorrectly.

Theare’sinnersurface

mustbeaw-free.

Thepipeendmust

beevenlyaredina

perfectcircle.

Makesurethatthe

arenutistted.

Check

A

Cutexactlyatrightangles. Removeburrs

Setexactlyatthepositionshownbelow.

A

0-0.02in

(0-0.5mm)

0.04-0.06in

(1.0-1.5mm)

0.06-0.08in

(1.5-2.0mm)

Clutch-type

FlaretoolforR410A

Clutch-type

(Rigid-type)

Wing-nuttype

(Imperial-type)

Conventionalaretool

Flaring

Die

WARNING

• Donotapplymineraloiltotheare.

• Prevent mineral oil from getting into the system as

this would reduce the service life of the units.

•

Never use piping which has been used for previous

installations. Only use parts which are delivered with this unit.

• Never install a dryer to this R410A unit in order to

guarantee its service life.

•

The drying material may dissolve and damage the system.

•

Incompletearingmayresultinrefrigerantgasleakage.

CAUTION

• Usethearenutxedtothemainunit.(Thisisto

preventthearenutfromcrackingasaresultof

deterioration over time.)

• Useapipecutterandaresuitableforthetypeof

refrigerant.

• To prevent gas leakage, apply refrigeration oil only to

theinnersurfaceoftheare.(Userefrigerationoilfor

R410A.) (Refer to Fig. 10)

• Useatorquewrenchwhentighteningthearenutsto

preventdamagetothearenutsandgasleakage.

•

Protect the open end of the pipe against dust and moisture.

•

Do not allow anything other than the designated

refrigerant to get mixed into the refrigerant circuit, such

as air, etc. If any refrigerant gas leaks while working on

the unit, ventilate the room thoroughly right away.

•

Useonlythearenutsattachedtotheairconditioner.If

otherarenutsareused,itmaycauserefrigerantleakage.

(2) Refrigerant piping

1. To prevent gas leakage, apply refrigeration machine

oilonlytotheinnersurfaceoftheare.(Use

refrigeration oil for R410A)

2.Alignthecentersofbotharesandtightentheare

nuts 3 or 4 turns by hand, then tighten them fully with

a spanner and a torque wrench.

• Useatorquewrenchwhentighteningthearenuts

topreventdamagetothearenutsandgasleakage.

(Refer to Fig. 9)

Flare nut tightening torque

Gas side Liquid side

3/8 inch

(9.5mm)

1/2 inch

(12.7mm)

5/8 inch

(15.9mm)

1/4 inch

(6.4mm)

24.1-29.4ft•lbf

(32.7-39.9N•m)

36.5-44.5ft•lbf

(49.5-60.3N•m)

45.6-55.6ft•lbf

(61.8-75.4N•m)

10.4-12.7ft•lbf

(14.2-17.2N•m)

7 English

Loading ...

Loading ...

Loading ...