Loading ...

Loading ...

Loading ...

16

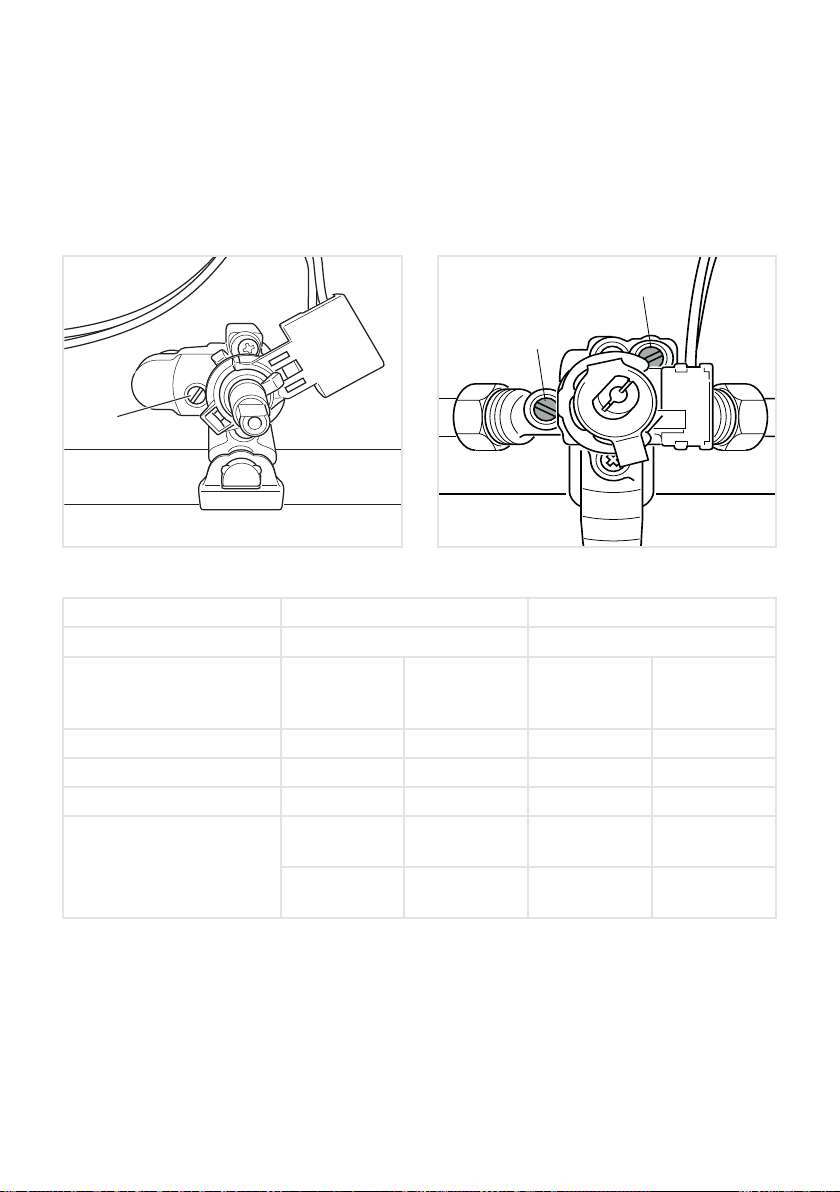

■ Using a screwdriver turn the screw “F2” until the correct setting is obtained (g. 15b).

Outside crowns of DUAL burner:

■ Light the DUAL burner.

■ Set the gas valve to the “minimum rate” position of the inner + outer crowns.

■ Remove the knob.

■ Using a screwdriver turn the screw “F3” until the correct setting is obtained (g. 15b).

Normally for ULPG, the regulation screw is tightened up.

TABLE FOR THE CHOICE OF THE INJECTORS

Natural gas ULPG

Test Point Pressure [kPa]

1.0 2.75

BURNER

Injector

Orice Dia.

[mm]

Gas

Consumption

[MJ/h]

Injector

Orice Dia.

[mm]

Gas

Consumption

[MJ/h]

Auxiliary (A) 0.85 3.60 0.53 3.60

Semi-rapid (SR) 1.12 6.30 0.70 6.30

Triple-ring (TR) 1.60 12.70 0.95 11.90

Dual (D)

0.85

(no.1 central)

3.60 (*)

0.50

(no.1 central)

3.20 (*)

1.15

(no.2 outer)

16.00 (**)

0.62

(no.2 outer)

13.00 (**)

(*)

Power calculated with only inner crown operating.

(**) Power calculated with inner and outer crowns operating.

LUBRICATION OF THE GAS VALVES

If a gas valve becomes stiff, it is necessary to dismantle it carefully and clean it with

petroleum spirit.

Specialist high temperature resistant grease should be used to lubricate the valve before

replacing.

The operations must be carried out by an authorised person/service agent.

F

Figure 15a

F1

G

H

Figure 15b

F2

F3

Loading ...

Loading ...

Loading ...