Loading ...

Loading ...

Loading ...

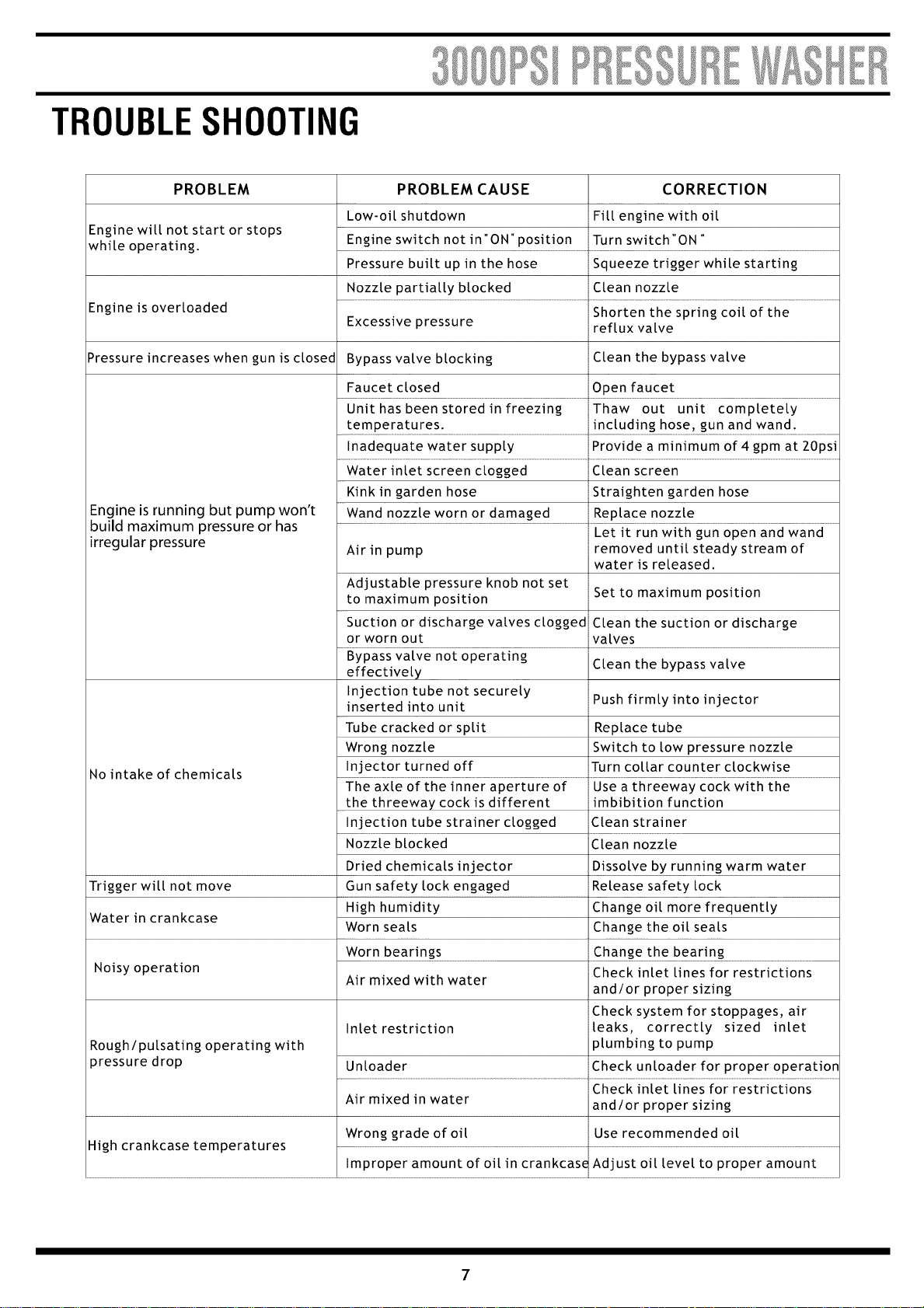

TROUBLESHOOTING

u8£o

PROBLEM

Engine wiU not start or stops

while operating.

Engine is overloaded

Pressure increases when gun is dosed

Engine is running but pump won't

build maximum pressure or has

irregular pressure

No intake of chemicals

Trigger will not move

Water in crankcase

Noisy operation

Rough/pulsating operating with

pressure drop

High crankcase temperatures

PROBLEM CAUSE CORRECTION

Low-oil shutdown Fill engine with oil

Engine switch not in"ON" position Turn switch" ON"

Pressure built up in the hose Squeeze trigger while starting

Nozzle partially blocked Clean nozzle

Shorten the spring coil of the

Excessive pressure reflux valve

Bypass valve blocking Clean the bypass valve

Faucet closed Open faucet

Unit has been stored in freezing Thaw out unit completely

temperatures, including hose, gun and wand.

Inadequate water supply Provide a minimum of 4 gpm at 20psi

Water inlet screen dogged Clean screen

Kink in garden hose Straighten garden hose

Wand nozzle worn or damaged Replace nozzle

Let it run with gun open and wand

Air in pump removed untit steady stream of

water is released.

Set to maximum position

Adjustable pressure knob not set

to maximum position

Suction or discharge valves clogged

or worn out

Clean the suction or discharge

valves

Bypass valve not operating

effectively Clean the bypass valve

Injection tube not securely

inserted into unit Push firmly into injector

Tube cracked or split

Wrong nozzle

Injector turned off

The axle of the inner aperture of Use a threeway cock with the

Replace tube

Switch to low pressure nozzle

Turn collar counter clockwise

the threeway cock is different

Injection tube strainer clogged

Nozzle blocked

Dried chemicals injector

Gun safety lock engaged

High humidity

Worn seals

Worn bearings

imbibition function

Clean strainer

Clean nozzle

Dissolve by running warm water

Release safety lock

Change oil more frequently

Change the oil seals

Change the bearing

Check inlet lines for restrictions

Air mixed with water

and/or proper sizing

Check system for stoppages, air

Inlet restriction leaks, correctly sized inlet

plumbing to pump

Unloader Check unloader for proper operation

Check inlet lines for restrictions

Air mixed in water and/or proper sizing

Wrong grade of oil Use recommended oil

Improper amount of oil in crankcase Adjust oil level to proper amount

7

Loading ...

Loading ...

Loading ...