Loading ...

Loading ...

Loading ...

MAINTENANCE

ENGINE MAINTENANCE

During the winter months, rare atmospheric

conditions may develope which will cause an icing

condition in the carburetor. If this develops, the

engine may run rough, Lose power and may stall.

This temporary condition can be overcome by

deflecting some of the hot air from the engine

over the carburetor area.

NOTE: Refer to the engine manufacturer's manual

for service and maintenance of the engine.

STORAGE 1

PUMP STORAGE

If you must store your pressure washer in a Location

where the temperature is below 320F, you can

minimize the chance of damage to your machine by

utilizing the foLLowing procedure:

1. Shut off water supply and relieve pressure in the

spray gun by depressing the trigger. Disconnect

the garden hose from the pressure washer, but

Leave the high pressure hose connected.

2. Tip the unit on its side with the inlet connection

pointing up.

3. Insert a smaLL funnel (to prevent spiLLing) into

the inlet and pour in approximately 1/4 cupof

RVantifreeze.

4. Disconnect spark plug wire.

5. Without connecting garden hose puLL the recoil

several times to circulate the antifreeze in the

pump system.

6. Disconnect spark plug wire.

2. Drain gasoline from fuel tank, fuel Line, fuel

valve and carburetor.

3. Pour about one teaspoon of engine oil through

the spark plug hole, puLL the recoil starter

sLowLy until you feel increased pressure which

indicates the piston is on its compression stroke

and leave it in that position. This c[osesboth

the intake and exhaust valves to prevent the

inside of the cylinder from rusting.

4. Cover the pressure washer and store in a clean,

dry place that is weLL ventilated away from

open flame or sparks.

NOTE: The use of a fuel additive, such as

STA-BIL, or an equivalent, will minimize the

formulation of fuel gum deposits during storage.

Such an additive may be added to the gasoline

in the fuel tank of the engine, or to the gasoline

in a storage container.

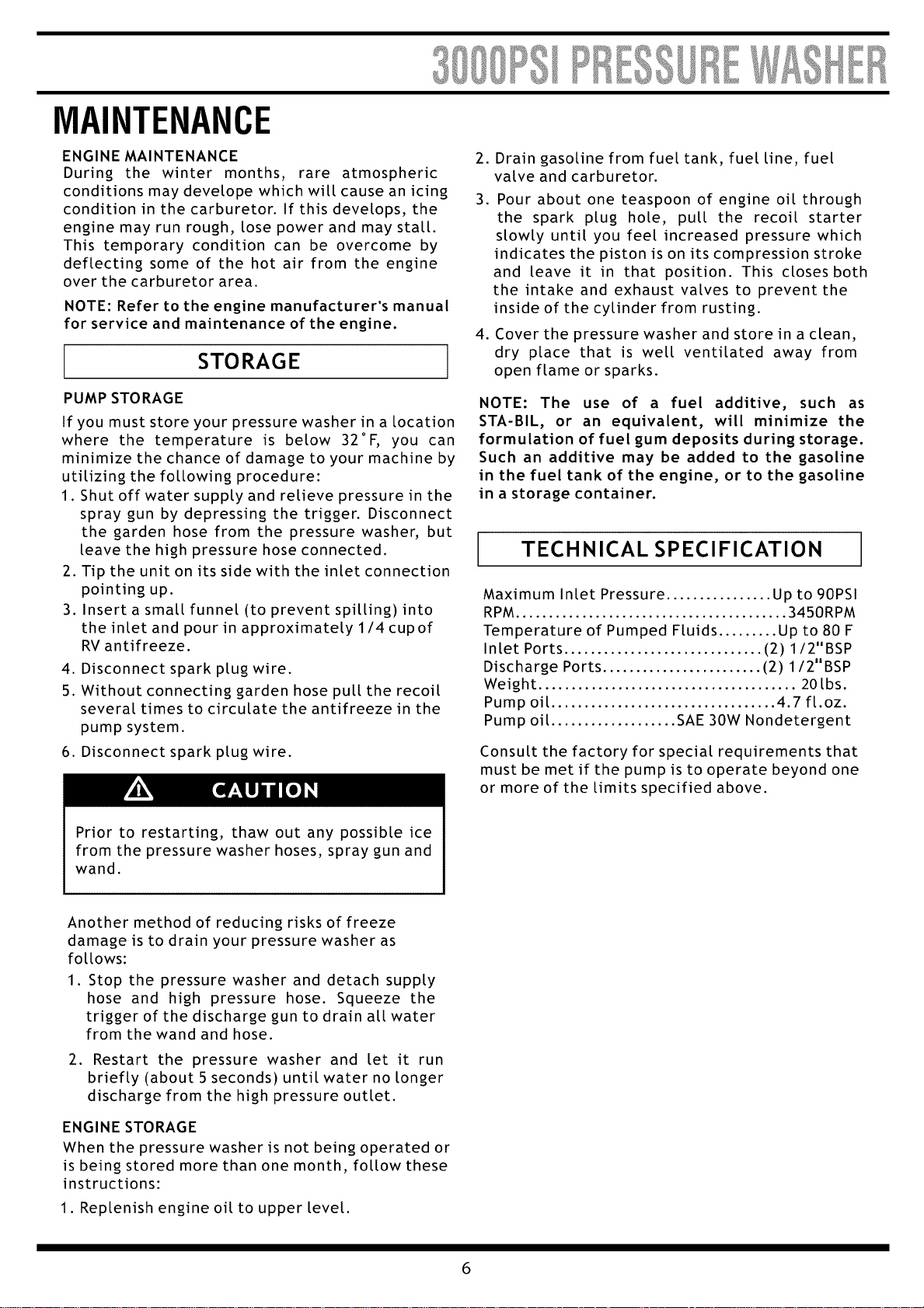

TECHNICAL SPECIFICATION

Maximum Inlet Pressure ................ Up to 90PSI

RPM......................................... 3450RPM

Temperature of Pumped FLuids ......... Up to 80 F

Inlet Ports .............................. (2) 112"BSP

Discharge Ports ........................ (2) 112"BSP

Weight ....................................... 20 [bs.

Pump oil .................................. 4.7 fL.oz.

Pump oil ................... SAE 30W Nondetergent

ConsuLt the factory for special requirements that

must be met if the pump is to operate beyond one

or more of the Limits specified above.

Prior to restarting, thaw out any possible ice

from the pressure washer hoses, spray gun and

wand.

Another method of reducing risks of freeze

damage is to drain your pressure washer as

foLLows:

1. Stop the pressure washer and detach supply

hose and high pressure hose. Squeeze the

trigger of the discharge gun to drain aLLwater

from the wand and hose.

2. Restart the pressure washer and Let it run

briefly (about 5 seconds) until water no Longer

discharge from the high pressure outlet.

ENGINE STORAGE

When the pressure washer is not being operated or

is being stored more than one month, follow these

instructions:

1. RepLenish engine oil to upper LeveL.

Loading ...

Loading ...

Loading ...