Loading ...

Loading ...

Loading ...

CAUTION

When the pumping has finished, close the Lo-lever of the

manifold valve completely and turn off the vacuum pump.

When you have pumped for over 15 minutes, please

confirm that the indicator of multimeter is on -1.0X10

-5

Pa

(-76cmHg)

Loosen and remove the nuts of service valves A and B to

open service valve A andB completely, then fasten nuts.

Disassemble the charge hose of service valve A, and

fasten the nut.

Both service valves should be open before test operation.

Each air conditioner has two service valves of different

sizes.(Refer to Fig.8-4)

Flare nut

Stopper

Cap

Valve body

Valve stern

9.2 Check the Leakage

Check all the joints with the leak detector or soap water. (Refer

Fig.9-5 as a reference illustration)

in the chart

A......Lo-stop valve

B......Hi-stop valve

C,D..Joints of the connecting pipe to the indoor unit.

B A

D

C

Check-point of indoor unit

Check-point of outdoor unit

-76 cmHg

Lo-lever

Hi-lever

Charge hose

Charge hose

Vacuum pump

Lo-lever

Manifold valve

Multi-meter

Pressure meter

Fig.9-3

Fig.9-4

9.3 Insulation

Be sure to completely insulate all the exposed parts of the flare

pipes.

Incomplete insulation may cause condensate.

Fig.9-5

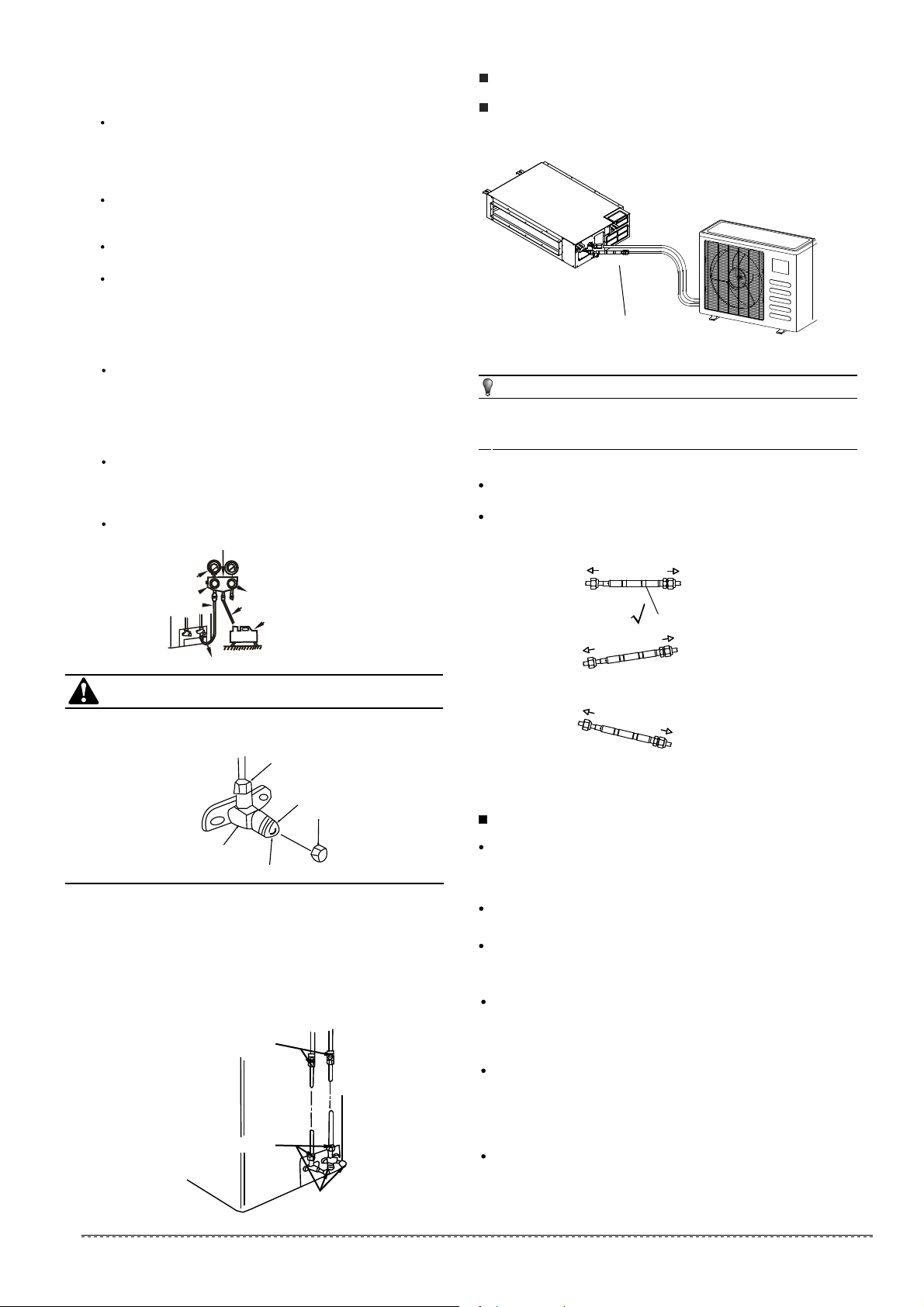

10. CONNECTIVE DIAGRAM

Orifice

Fig. 10-1

Fig. 10-2

For ensuring throttled efficiency, Please mount the Orifice as

horizontally as possible; and anti-shock rubber should be

wrapped at external of the Orifice for denoise.

NOTE

Please purchase the fittings according to the requirements in

the manual strictly.

Refer the diagram when installing.

Mark the data plate with the Orifice installed.(for some models)

Liquid side

Liquid side

Indoor

Indoor

Outdoor

Outdoor

X

Liquid side

Indoor

Outdoor

X

NOTE:the orifice should be horizontally installed.

Liquid side

Gas side

Expel the air with a vacuum pump(Refer to Fig.9-3)

3

(Please refer to its manual for the way of using manifold

valve)

18

installation manual

11. CONNECT THE DRAIN PIPE

Install the drainpipe of the indoor unit

Use a polyethylene tube as the drainpipe (out-dia. 1.14-1.22in

/29-31mm, in-dia. 0.984in/25mm). It could be bought from the

local market.

When extending drainpipe,tighten the connector with

water-proof tape to prevent it leakage.

Please lean the drainpipe down toward outdoor (outlet-side)

at a degree of over 1/ 50 to avoid water flowing back. And

please avoid any bulge.

Do not drag the drainpipe violently. Meanwhile, one

supportpoint should be set every 3.28~4.92ft/1~1.5m to

prevent the drainpipe from yielding. Or tie the drainpipe with

the connecting pipe to fix it.

If the outlet of the drainpipe is higher than the body's pump

joint, the pipe should be arranged as vertically as possible.

And the lift distance must be less than 21.65in/550mm,

otherwise the water can not be lifted completely and cause

overflow.(Only available for the unit with pump.)

The end of the drainpipe should be over 1.969in/50mm higher

than the ground , and do not immerse it in water. If you

discharge the water directly into sewage, be sure to make a

U-form aquaseal by bending the pipe up to prevent the smelly

gas entering the house through the drain pipe.

Loosen and remove the nuts of service valves A and B,

and connect the charge hose of the manifold valve with

the maintenance terminator of service valve A. (Be sure

that service valves A and B are both closed)

Connect the joint of the charge hose with the vacuum

pump.

Open the Lo-lever of the manifold valve completely.

Turn on the vacuum pump. At the beginning of pumping,

loosen the nut of service valve B a little to check whether

the air comes in (the sound of the pump changes, and

the indicator of compound meter turns below zero). Then

fasten the nut.

For more details visit www.mrcool.com

Loading ...

Loading ...

Loading ...