Loading ...

Loading ...

Loading ...

Fig.8-2

10°

10°

A

Fig.8-3

The branching pipe must be installed horizontally, error angle

of it should not large than 10°. Otherwise, malfunction will be

caused.

CorrectWrong

U-shaped branching pipe

Horizontal surface

A direction view

1)

Use the vacuum pump which vacuum level lower than

-0.1MPa and the air discharge capacity above 40L/min.

The outdoor unit is not necessary to vacuum, don’t open the

outdoor unit gas and liquid pipe shut-off valves.

Make sure the vacuum pump could result as -0.1MPa or

below after 2 hrs or above operation. If the pump operated 3

hrs or above could not achieve to -0.1MPa or below, please

check whether water mix or gas leak inside of the pipe.

8.4 Vacuum with vacuum pump

1)

2)

3)

CAUTION

8.5 Refrigerant amount to be added

Calculate the added refrigerant according to the diameter and

the length of the liquid side pipe of the outdoor/indoor unit

connection. The refrigerant is R410A.

Pipe size on

liquid side

Refrigerant to

be Added per meter

Φ6.35/0.25in

Φ9.52/0.375in

0.015kg/0.033lb

0.030kg/0.066lb

Table.8-4

Don’t mix up the different refrigerants or abuse the tools and

measurements which directly contact with refrigerants.

Don’t adopt refrigerant gas for air vacuuming.

If vacuum level could not get to -0.1MPa, please check whether

resulted by leakage and confirm the leakage site.If no leakage,

please operate the vacuum pump again 1 or 2 hrs.

Connect with vacuum pump

Perform the pump (last for 2 hrs or above)

When get the vacuum level

-0.1MPa, the pump should

keep running for 20-60 mins

Shut down the

vaccun pump

Place the vaccum state unused (1 hrs or above)

1. Close-off the valve of

vacuum meter.

2. Cut off the connection

between pressure meter

and vacuum pump.

3. Close the vacuum

pump.

CAUTION

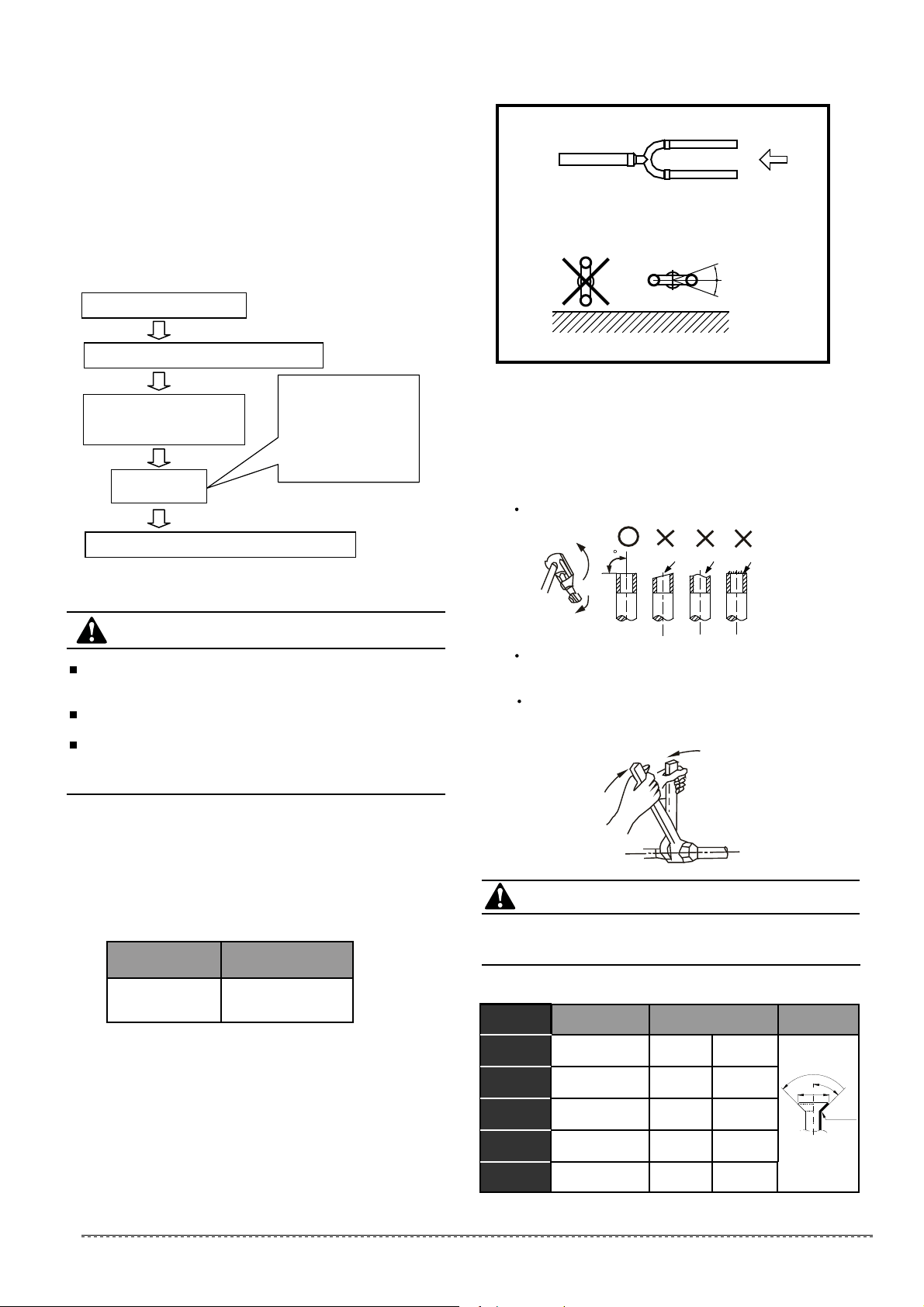

Flaring

1

Cut a pipe with a pipe cutter. (Refer to Fig.9-1)

Table 9-1

Insert a flare nut into a pipe and flare the pipe.

Fig.9-1

(mm)

Ø6.35/0.25in 0.327in/8.3 0.343in/8.7

Ø9.52/0.375in 0.472in/12.0 0.488in/12.4

Ø12.7/0.5in 0.606in/15.4 0.622in/15.8

Ø15.9/0.626in

Ø19.1/0.725in

0.732in/18.6 0.748in/19.0

0.902in/22.9 0.917in/23.3

R0.4~0.8

45

°

±

2

90

°

±

4

A

min max

Pipe gauge

Tightening torque

Flare dimensin A

Flare shape

97.2~118.6 N.m

(990~1210 kgf.cm)

(630~770 kgf.cm)

61.8~75.4 N.m

49.5~60.3 N.m

(504~616 kgf.cm)

32.7~39.9 N.m

(333~407 kgf.cm)

14.2~17.2 N.m

(144~176 kgf.cm)

9.1 Expel The Air

Fasten the nut

2

Put the connecting pipes at the proper position,

wrench the nuts with hands then fasten it with

two wrenches simultaneously. (Refer to Fig.9-2)

Fig.9-2

Too large torque will harm the bellmouthing and too small will

cause leakage. Please determine the torque according to

Table 9-1.

9. REFRIGERANT PIPE CONNECTION

90

Lean crude burr

17

installation manual

For more details visit www.mrcool.com

Loading ...

Loading ...

Loading ...