Loading ...

Loading ...

Loading ...

Troubleshooting

21

TROUBLESHOOTING INFORMATION

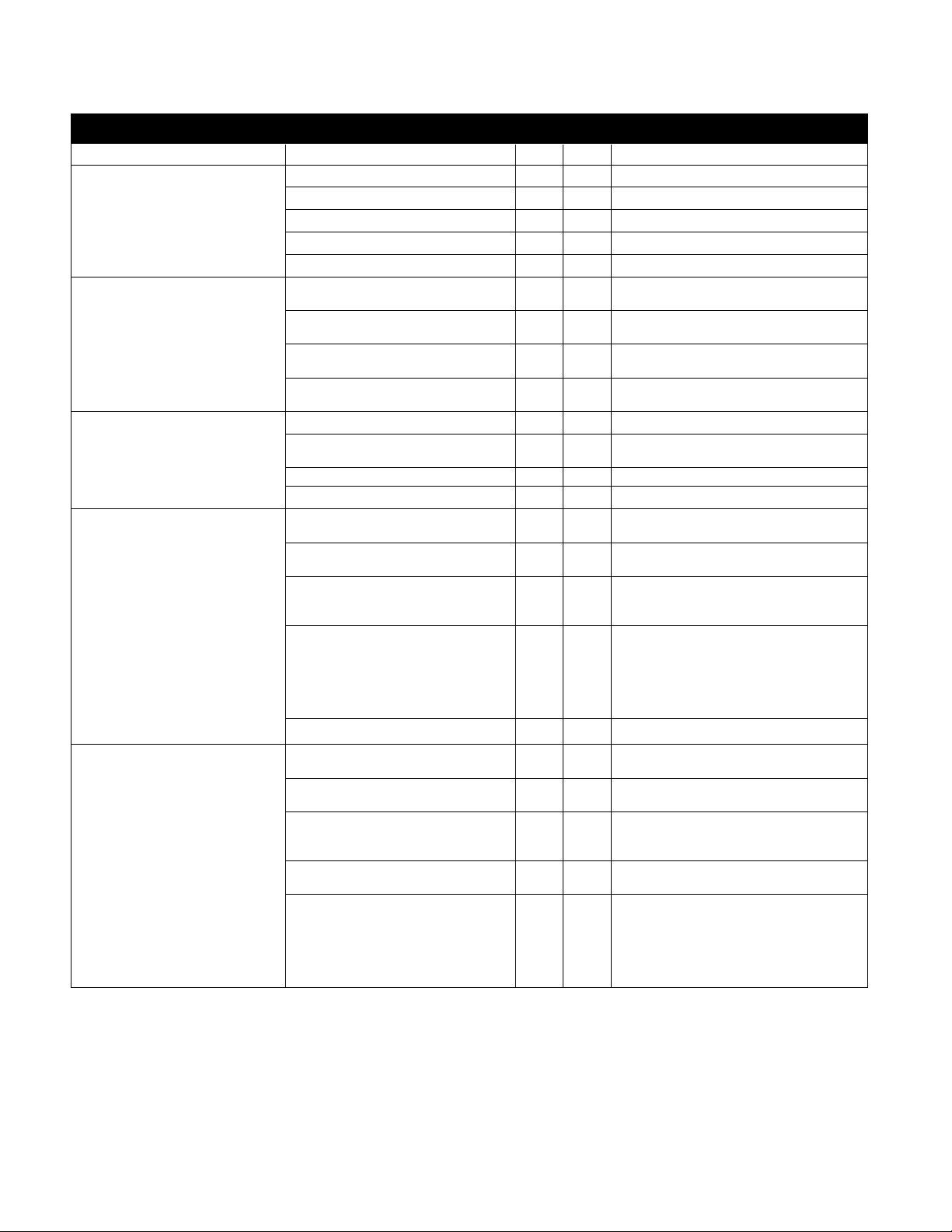

PROBLEM PROBABLE CAUSES 115 V 12 V CORRECTIVE ACTION

Pump does not turn on or turn o.

Bad connection X X Plug-in pump

Blown fuse X Turn on circuit breaker or replace fuse

Bad battery X Replace battery

Pump impeller obstructed X X Pull pump and clean

Pump control switch X X Replace switch

Pump does not deliver

rated capacity.

Low battery X

When power is restored, the charger will

charge the battery

Check valve installed backwards X X

Check ow indication arrow on check valve

body to ensure it is installed properly

Low voltage, speed too slow X X

Check for proper supply voltage to make

certain it corresponds to name plate voltage.

Impeller or discharge pipe is clogged X X

Pull pump and clean. Check pipe for scale or

corrosion

Pump cycles continually.

Defective battery X Replace battery

No check valve in long discharge pipe

allowing liquid to drain back into sump.

X X Install a check valve in discharge line

Check valve leaking X X Inspect check valve for correct operation

Sump pit too small for inow X X Install larger sump pit

Pump will not shut o.

NOTE: Before troubleshooting

automatic control, check to see that

pump operates on manual control.

To do this, create slight vacuum on

breather tube (near plug), then close

o tube with thumb, plug into wall

outlet. If pump works, proceed to

check switch; if not, fault is in pump

or power supply.

Pump control switch X X Replace switch

Plugged vent tube X Clear vent tube of any obstruction

Dirt or sediment lodged between

retainer ring and rubber diaphragm

causing contacts to remain closed

X Clean area around rubber diaphragm

Pump is air locked X X

Shut power o for approximately 1 minute,

then restart. Repeat several times to clear

air from pump. If system includes a check

valve, a 3/16" hole should be drilled in the

discharge pipe between the pump discharge

and the check valve.

Liquid inow matches pump capacity X X Larger pump required

Pump runs but does not

discharge liquid.

Check valve installed backwards X X

Check ow indicating arrow on check valve

body to ensure it is installed properly.

Check valve stuck or plugged X X

Remove check valve and inspect for proper

operation

Lift too high for pump X X

Check pump performance as compared to

the vertical distance needed to evacuate the

sump water

Inlet to impeller plugged X X Pull pump and clean

Pump is air locked X X

Shut power o for approximately 1 minute,

then restart. Repeat several times to clear

air from pump. If system includes a check

valve, a 3/16" hole should be drilled in the

discharge pipe between the pump discharge

and the check valve.

Loading ...

Loading ...

Loading ...