Loading ...

Loading ...

Loading ...

9

Preparation and Setup

To determine your maximum length:

Start with the your duct run’s total max. length, then sub-

tract all of the ductwork equivalent lengths. (See the chart.)

Ductwork Equivalent Lengths

Piece Subtract

8” 90° Elbow 7 feet

8” 45° Elbow 3 feet

10” 90° Elbow 5 feet

10” 45° Elbow 2 feet

3” x 10” to Round 90° Transition 25 feet

3¼” x 10” to 8”/10” Round Transition 4 feet

Wall Cap w/Damper

*

Roof Cap

*Equivalent lengths of roof and wall caps vary with model and

configuration.

Ductwork Tips

• Try to minimize transitions, turns, and sharp angles (e.g.,

two staggered 45° angles are better than one sharp 90°

angle).

• Keep turns as far away from the hood exhaust as pos-

sible; keep as much space between bends as possible.

• For best performance, use round instead of rectangular

ducting, especially when elbows are needed.

• If multiple elbows are used, try to keep at least 24 inches

of straight duct between each elbow.

• Avoid using “S” or back-to-back adjacent elbows.

• In extremely cold-weather regions, use thermal breaks

(i.e., short sections of non-metallic duct) to avoid indoor

heat loss. Locate the break as close to the outside pass-

through point as possible.

• Do not use flexible metal ducting, or ductwork smaller

than what the tables advise.

• The hood exhaust connects to an 8” round duct. You can

increase the duct size over the duct run if desired.

• To prevent backdraft, never decrease the duct size over

the run. If existing ductwork is less than 8 inches in diam-

eter, replace it with 8” ductwork.

• Connect all ducting sections with sheet-metal screws,

then seal with certified duct/foil tape. Never connect joints

with tape only.

• Support the weight of the ducting with sheet-metal

screws as needed.

• To prevent backdraft, a damper at the duct outlet may be

required.

WARNING

• Electricity to the range hood should be installed only by

a licensed electrician.

• Observe all governing codes and ordinances during

site preparation and installation. Contact your local

building department for details.

• Improperly anchoring the hood to the wall may cause

personal injury if unit falls.

• To prevent personal injury and property damage from

electric shock, do not drill or cut in the vicinity of plumb-

ing and electrical wiring.

• Use the temporary holding brackets to support the

hood only until permanent anchoring is secured.

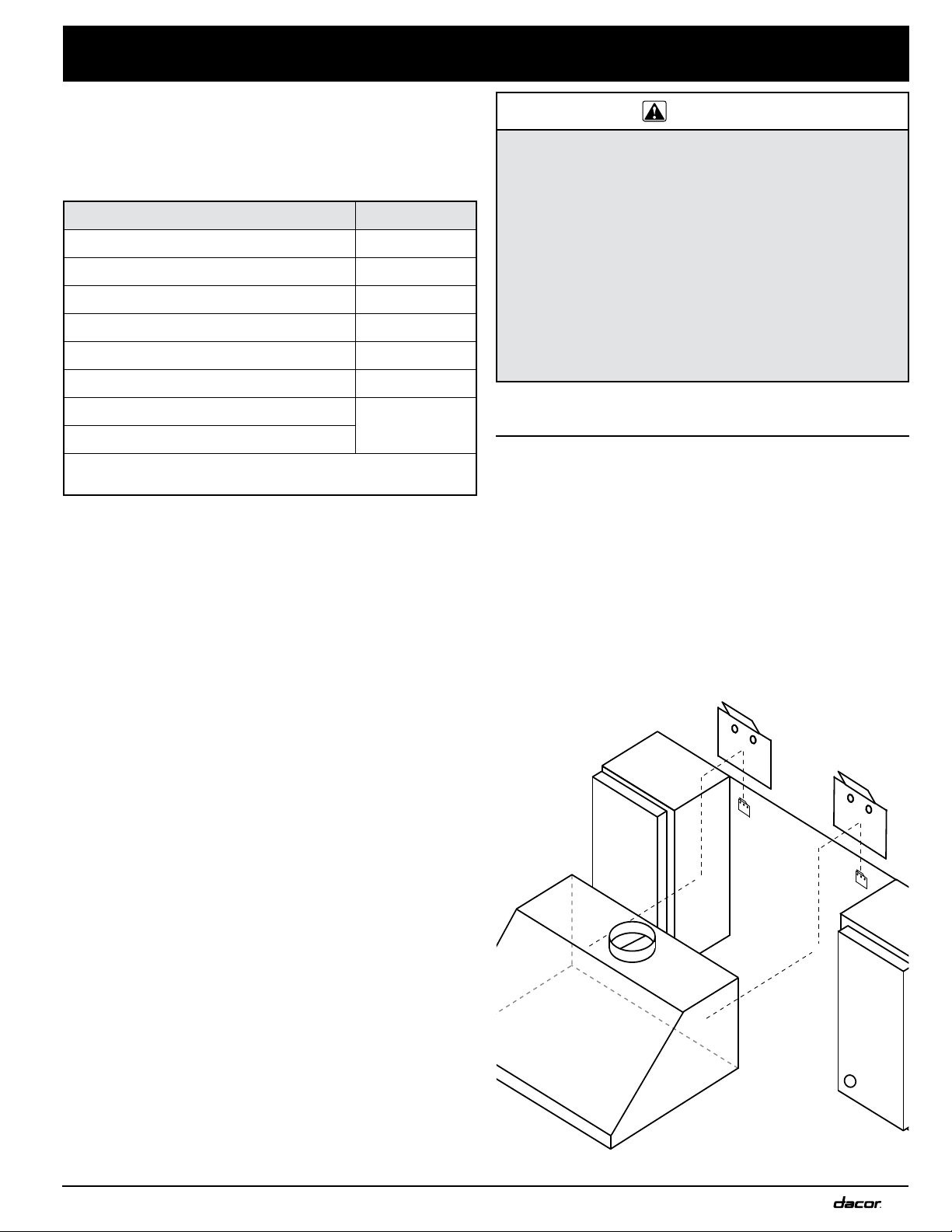

Holding Brackets

Brackets enlarged

for clarity

Preparing the Mounting Location

Holding brackets and hardware are provided to temporarily

support the hood as you permanently fasten it to the wall.

The illustrations below show the purpose of the holding

brackets and the support behind the wall.

• (If mounting the hood to brick or masonry) Select anchors

that can support the hood’s full weight.

• Ensure the mounting surface is properly reinforced to

support the hood’s full weight.

• If mounting the unit to drywall or a plastered surface,

install a reinforced mounting block between the studs.

• Attach screws directly to the studs and cabinets if they

align with the mounting holes in the hood back/top.

Loading ...

Loading ...

Loading ...