Loading ...

Loading ...

Loading ...

8

MILK COOLERS FORCED AIR & COLD WALL

OPERATIONS MANUAL

The system should run smoothly and quietly in accordance with

generally accepted commercial standards. If any unusual noises

are heard, turn the unit off immediately and check for obstruc-

tions of the condenser or evaporator fans. Fan motors, blades,

and housings can be jarred out of position through rough han-

dling in transit.

CAUTION: IF POWER IS DISCONNECTED FOR ANY

REASON, ALLOW 5 MINUTES FOR THE SYSTEM TO

EQUALIZE BEFORE TURNING THE UNIT BACK ON.

DISREGARDING THIS PROCEDURE MAY CAUSE AN

OVERLOAD AND PREVENT THE UNIT FROM OPERATING!

OPERATION

REFRIGERATION SYSTEM AND ADJUSTMENT

(Cold Wall)

All self-contained “cold wall” milk cooler refrigerators are

designed and factory set to maintain an average cabinet temper-

ature of 36°F. Note that adjusting a cabinet too cold (below the

“Cut-In” setting of 30°F) could result in freezing your product

over long periods of time. Further adjustments out of the factory

design temperature range must be made by a qualified refrig-

eration mechanic only. The cold wall system operates by wall

temperatures reaching below freezing (approximate wall tem-

perature is 20°F) and should periodically be manually defrosted

to minimize wall ice accumulation. To manually defrost your

milk cooler, unload all product and place it in a refrigerated stor-

age unit. Keep the lids and doors open, and disconnect power

to the cabinet (by unplugging the power cord) for approximately

30 minutes allowing the frost to melt and drain to the floor drain.

Care should be taken not to scrape and potentially puncture the

wall since the refrigeration tubing is located behind the wall and

could be damaged.

REFRIGERATION SYSTEM AND ADJUSTMENT

(Forced Air)

All self-contained “forced air” milk cooler refrigerators are

designed and factory set to maintain an average cabinet tem-

perature of 36°F. Due to the open-type design and use of milk

coolers, it is normal for condensation to periodically form

around the door and lid seams and hinges, particularly if the

temperature has been set too cold. If moisture becomes exces-

sive check, the control settings (see “How to Change the Set

Point” on page 9) .

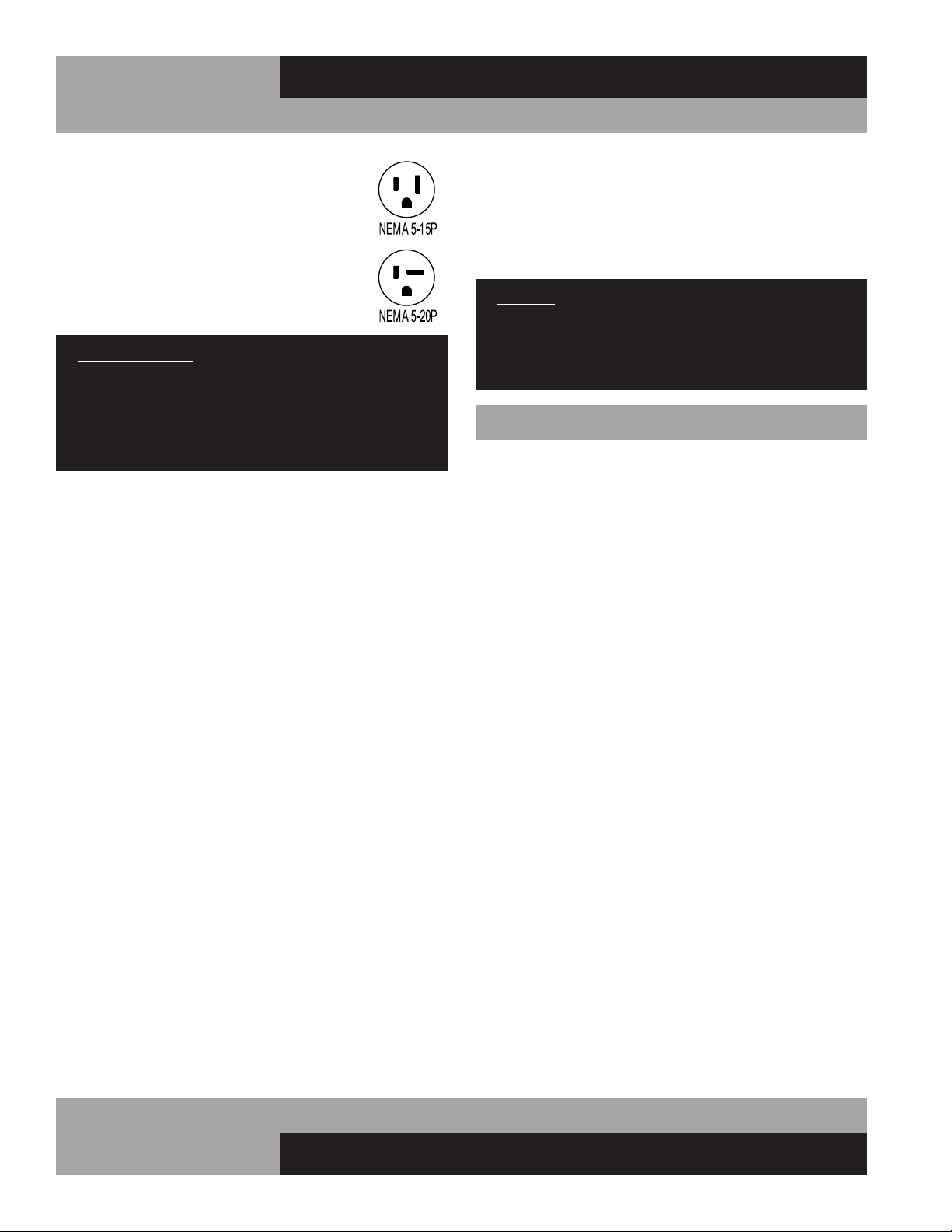

115 VOLT, 60 HZ, 1 PHASE CONNECTION

All 115 volt models are provided with a factory

installed, UL approved 15-amp power cord and

NEMA 5-15P plug, or a 20-amp power cord and

NEMA 5-20P plug. To insure proper operation,

this equipment must be plugged into a NEMA

compatible, grounded receptacle that can supply

the full voltage and amperage stated on the serial

plate (see Figure 1).

IMPORTANT NOTE: A SEPARATE, ISOLATED, PROPERLY

SIZED POWER SUPPLY MUST BE PROVIDED. GFCI

DEVICES AND/OR EXTENSION CORDS SHOULD NOT

BE USED. PRODUCT LOSS, AS WELL AS PROBLEMS

RESULTING FROM NUISANCE TRIPS OR HIGH/LOW

VOLTAGE, ARE NOT COVERED UNDER WARRANTY.

SPECIAL VOLTAGE CONNECTIONS

When models are ordered from the factory with special, optional

voltages, connections should be made as required on the

electrical wiring diagram provided on the inside compressor

compartment rear next to the electrical console box.

START-UP CHECKLIST

After your unit has been installed and power connected in

accordance with this manual, please take time to check the fol-

lowing before loading product, to assure trouble-free operation:

Cabinet location suitable and unit is level

(see “Installation and Location”)

Seperate power supply with correct voltage

(see “Electrical Connections”)

Drain hose routed to floor drain

(see “Installation and Location”)

Vaporizer connected

(see “Evaporator Condensate Removal”)

Doors and lids close and seal properly

(see “Door Latch and Lid Lock”)

Cold Wall Models: Correct cabinet temperature

(see “Cold Wall Refrigeration System and Adjustment”

or “Operation with Electronic Control”)

Forced Air Models: Correct cabinet temperature

(see “Forced Air Refrigeration System and Adjustment”)

or “Operation with Electronic Control”)

Refrigeration lines free of kinks and vibration

(see “Refrigeration System

All packaging discarded and cabinet cleaned

(see “Periodic Cleaning”)

09/03/10

Loading ...

Loading ...

Loading ...