Loading ...

Loading ...

Loading ...

14

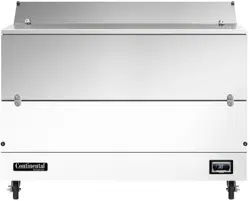

MILK COOLERS FORCED AIR & COLD WALL

OPERATIONS MANUAL

OBTAINING REPLACEMENT

PARTS UNDER WARRANTY

If replacement parts are required for a unit under warranty,

contact Continental’s Service Department. New parts will be

sent from the factory and, when applicable, a Return Goods

Authorization (RGA) will be issued to return old parts. The RGA

number must appear on the packaging of any parts returned, or

they will not be accepted. If a service agent uses a part from their

stock, Continental will replace it with a factory part.

OBTAINING REPLACEMENT

COMPRESSOR UNDER WARRANTY

If the compressor should fail within the first twelve (12) months

of use, or within twenty (20) months from the date code on the

compressor, an “over-the-counter” exchange must be made

at an authorized Copeland, Danfoss, Embraco, or Tecumseh

wholesaler.

After the first year, the compressor motor is covered under an

extended “parts only” warranty. The customer is responsible for

any labor charges and any additional parts that may be required.

Contact the Service Department to obtain a replacement com-

pressor through one of the following methods:

• Continental will supply a replacement compressor

at no charge and pay for regular freight. (If expe-

dited freight is requested, the end user, dealer or

service agent is responsible for additional charg-

es and must provide credit card information.

• A compressor can be purchased locally and

Continental will either replace the stock unit with

a new factory compressor, or offer an allowance

towards the purchase of a replacement compres-

sor, up to: $100 for 1/5hp to 1/3hp; $250 for

1/2hp to 3/4hp; $350 for 1hp to 2hp.

The data tag from the defective compressor (or compres-

sor model, serial number and date code, if the tag cannot be

removed) must be included with any reimbursement request.

END-OF-LIFE DISPOSAL

OF REFRIGERATED EQUIPMENT

Your unit is designed and built to provide many years of reli-

able service. At the end of its useful life, please follow the steps

below for safe disposal, to help avoid accidents and to protect

the environment.

1. Remove all doors, to eliminate any potential for accidental

child entrapment.

2. All refrigerant should be removed from the system by a

qualified technician and disposed of properly, or reclaimed.

(Intentional venting of many refrigerants into the air is harm-

ful and prohibited; violators are subject to fines). All refriger-

ant oil should be drained from the compressor and discarded

appropriately.

3. Properly dispose of the cabinet and refrigeration system

components. The majority of the metal in your unit (stainless

steel or aluminum cabinet shell and doors, steel shelving and

compressor, copper refrigerant lines, etc.) can be recycled.

Many recycling facilities will dispose of the unit free of

charge, or pay you for scrap value of the material content.

Loading ...

Loading ...

Loading ...