Loading ...

Loading ...

Loading ...

7

OPERATIONS MANUAL

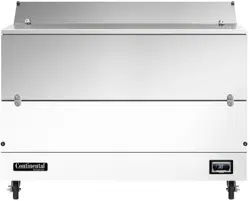

MILK COOLERS FORCED AIR & COLD WALL

START-UP PROCEDURE

ELECTRICAL CONNECTIONS

To insure proper operation, your new model must be connected

to an individual circuit that can supply the full voltage as stated

on the cabinet serial data plate. For correct voltage, power draw,

and wire accommodations, check the data on the serial data

plate located on the inner right wall of your new model. Verify

that this information exactly matches the electrical character-

istics at the installation location. An electrical wiring diagram,

located on the inside compressor compartment rear, next to

the electrical console box, should also be consulted during

connection. For reference, a copy of each electrical wiring dia-

gram is located towards the back of this manual (see “Wiring

Diagrams” section).

Refrigeration compressors are designed to operate within

+/-10% of the rated voltage indicated on the cabinet serial

plate. Excessively high or low supply power can burnout the

compressor. This can be easily detected and will void the fac-

tory warranty. Full voltage at the correct rating, on a separate,

designated circuit, not affected by the operation of other electri-

cal appliances, must be available to the refrigeration unit at all

times. Extension cords should never be used on commercial

equipment, as they can overheat and/or result in low voltage.

GFI/GFCI RECEPTACLES

Ground-Fault Circuit Interrupter (GFCI or GFI) devices are not

recommended for most commercial refrigerators and freez-

ers, since nuisance trips may occur, typically due to moisture.

This can cause temporary loss of power, which may result in

high storage temperatures and potentially unsafe food product.

Building codes in some areas may require certain 115 volt

receptacles to be protected by a GFI If you need to connect your

equipment to a protected circuit, a properly sized, commercial

grade GFI circuit breaker should be used on a separate, isolated

power supply. Or a qualified electrician may be able to hard wire

your equipment, eliminating the need for a GFI device. Contact

Continental’s Service Department before making any modifica-

tions to your cabinet, to avoid loss of warranty.

NOTE: GFI RECEPTACLES ARE NOT RECOMMENDED,

PRODUCT LOSS OR SERVICE PROBLEMS RESULTING

FROM NUISANCE TRIPS, CONNECTION TO A DEFECTIVE

OR IMPROPER POWER SUPPLY, AND UNAUTHORIZED

MODIFICATIONS TO YOUR EQUIPMENT CAN CAUSE A

HAZARD AND WILL VOID FACTORY WARRANTY.

REMOVAL OF TOP ASSEMBLY (Forced Air Models Only)

The top assembly can be removed, by a qualified technician,

to access the evaporator coil, fans and related components

(see Figure 5). Removal and replacement will require a Philips

screwdriver, razor knife, tube of NSF-approved silicone seal-

ant and a silicone gun. To begin, open the front door and lid.

Remove the lid hinge screws from the top assembly. On single

access models, remove the joiner strip and screws from the

back of the cabinet (see Figure 3). For dual access models,

remove the screws from the hinges on the back Llid (see

Figure 4). Set the lid(s), hinges and other parts aside. Use a

razor knife to carefully score the silicone seal around the base

of the top assembly. BE EXTREMELY CAREFUL to avoid cutting

yourself or scratching your milk cooler. From inside the storage

compartment, remove screws from the underside of the top

assembly. Gently lift the top assembly straight up and off the

cabinet. To reattach the top, clean all excess sealant, reverse the

above steps and use silicone to provide an airtight seal between

the top and cabinet.

INTERIOR ACCESSORIES

The standard interior accessory package that is supplied from

the factory with your milk cooler model consists of an epoxy-

coated, steel wire floor rack (see Figure 2) which sits on the

interior stainless steel floor (MC5 models receive two) with the

legs facing down, as shown. A rubber stopper is also provided

for the floor drain.

INITIAL CLEANING PROCEDURE

Prior to start-up and before placing any product inside of your

new model, the interior of the cabinet should be thoroughly

cleaned. Remove the protective film (which is clear on some

models) from all interior sides, bottom and other internal metal

panels, by working the corner loose and slowly pulling the film

back. Washing with a mild soap and warm water solution is

recommended for cleaning the aluminum and stainless steel

surfaces of your cabinet. This should be followed by cleaning

with a baking soda solution (three (3) tablespoons of baking

soda to each quart of warm water). Wipe down thoroughly with

a damp cloth or sponge that has been soaked in clean water and

wrung out thoroughly, and dry with a clean, soft cloth.

IMPORTANT NOTE: Never use harsh detergents, clean-

ers, scouring powders or chemicals when cleaning your

model. Failure to dry the interior surfaces after cleaning

may result in a streaking or staining of the metal.

Complete cleaning procedures and precautions are listed in the

(“Periodic Cleaning Procedure” under “Maintenance”).

Loading ...

Loading ...

Loading ...