Loading ...

Loading ...

Loading ...

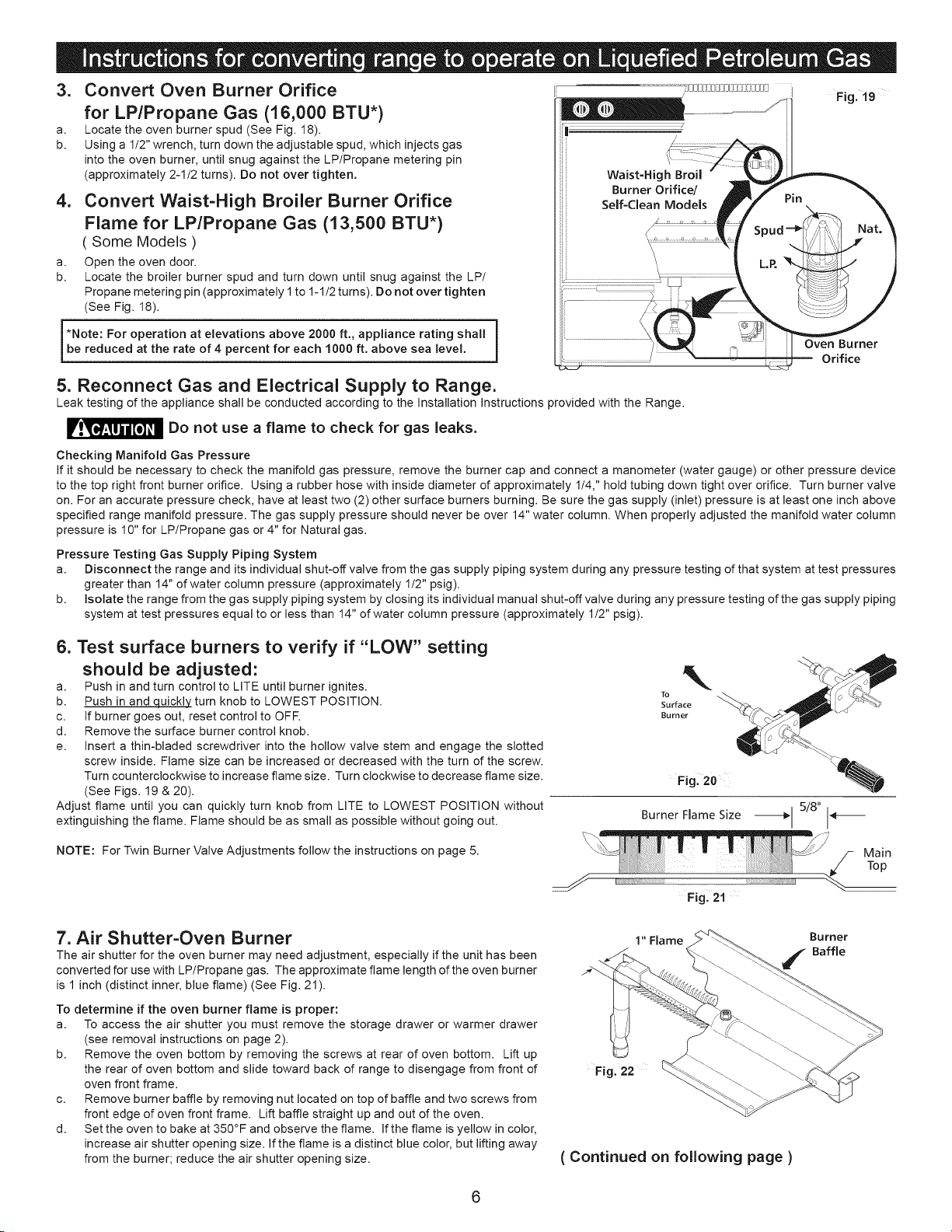

3. Convert Oven Burner Orifice I

Fig. t9

for LP/Propane Gas (16,000 BTU*)

a. Locate the oven burner spud (See Fig. 18).

b. Using a 1/2" wrench, turn down the adjustable spud, which injects gas

into the oven burner, until snug against the LP/Propane metering pin

(approximately 2-1/2 turns). Do not over tighten.

4. Convert Waist=High Broiler Burner Orifice

Flame for LP/Propane Gas (13,500 BTU*)

( Some Models )

a. Open the oven door.

b. Locate the broiler burner spud and turn down until snug against the LP/

Propane metering pin (approximately 1to 1-1/2 turns). Do not over tighten

(See Fig. 18).

I*Note: For operation at elevations above 2000 ft,, appliance rating shallbe reduced at the rate of 4 percent for each 1000 ft. above sea level,

Oven Burner

Orifice

5. Reconnect Gas and Electrical Supply to Range.

Leak testing of the appliance shall be conducted according to the Installation Instructions provided with the Range.

Do not use a flame to check for gas leaks.

Checking Manifold Gas Pressure

If it should be necessary to check the manifold gas pressure, remove the burner cap and connect a manometer (water gauge) or other pressure device

to the top right front burner orifice. Using a rubber hose with inside diameter of approximately 1/4/' hold tubing down tight over orifice. Turn burner valve

on. For an accurate pressure check, have at least two (2) other surface burners burning. Be sure the gas supply (inlet) pressure is at least one inch above

specified range manifold pressure. The gas supply pressure should never be over 14" water column. When properly adjusted the manifold water column

pressure is 10" for LP/Propane gas or 4" for Natural gas.

Pressure Testing Gas Supply Piping System

a. Disconnect the range and its individual shut-off valve from the gas supply piping system during any pressure testing of that system at test pressures

greater than 14" of water column pressure (approximately 1/2" psig).

b. Isolate the range from the gas supply piping system by closing its individual manual shut-off valve during any pressure testing of the gas supply piping

system at test pressures equal to or less than 14" of water column pressure (approximately 1/2" psig).

6. Test surface burners to verify if "LOW" setting

should be adjusted"

a. Push in and turn control to LITE until burner ignites.

b. Push in and quickly turn knob to LOWEST POSITION.

c. if burner goes out, reset control to OFR

d. Remove the surface burner control knob.

e. insert a thin-bladed screwdriver into the hollow valve stem and engage the slotted

screw inside. Flame size can be increased or decreased with the turn of the screw.

Turn counterclockwise to increase flame size. Turn clockwise to decrease flame size.

(See Figs. 19 & 20).

Adjust flame until you can quickly turn knob from LITE to LOWEST POSITION without

extinguishing the flame. Flame should be as small as possible without going out.

NOTE: For Twin Burner Valve Adjustments follow the instructions on page 5.

%

To

Surface

Burner

Fig: 20

Burner Flame Size

%

Main

Top

Fig: 21

7. Air Shutter=Oven Burner

The air shutter for the oven burner may need adjustment, especially if the unit has been

converted for use with LP/Propane gas. The approximate flame length of the oven burner

is 1 inch (distinct inner, blue flame) (See Fig. 21).

To determine if the oven burner flame is proper:

a. To access the air shutter you must remove the storage drawer or warmer drawer

(see removal instructions on page 2).

b. Remove the oven bottom by removing the screws at rear of oven bottom. Lift up

the rear of oven bottom and slide toward back of range to disengage from front of

oven front frame.

c. Remove burner baffle by removing nut located on top of baffle and two screws from

front edge of oven front frame. Lift baffle straight up and out of the oven.

d. Set the oven to bake at 350°F and observe the flame. If the flame is yellow in color,

increase air shutter opening size. if the flame isa distinct blue color, but lifting away

from the burner; reduce the air shutter opening size.

1" Flame

Fig. 22

( Continued on following page )

Loading ...

Loading ...