Loading ...

Loading ...

Loading ...

SECTION 6- ADJUSTMENTS & REPAIRS

6.13 CUTTING BLADE SERVICE

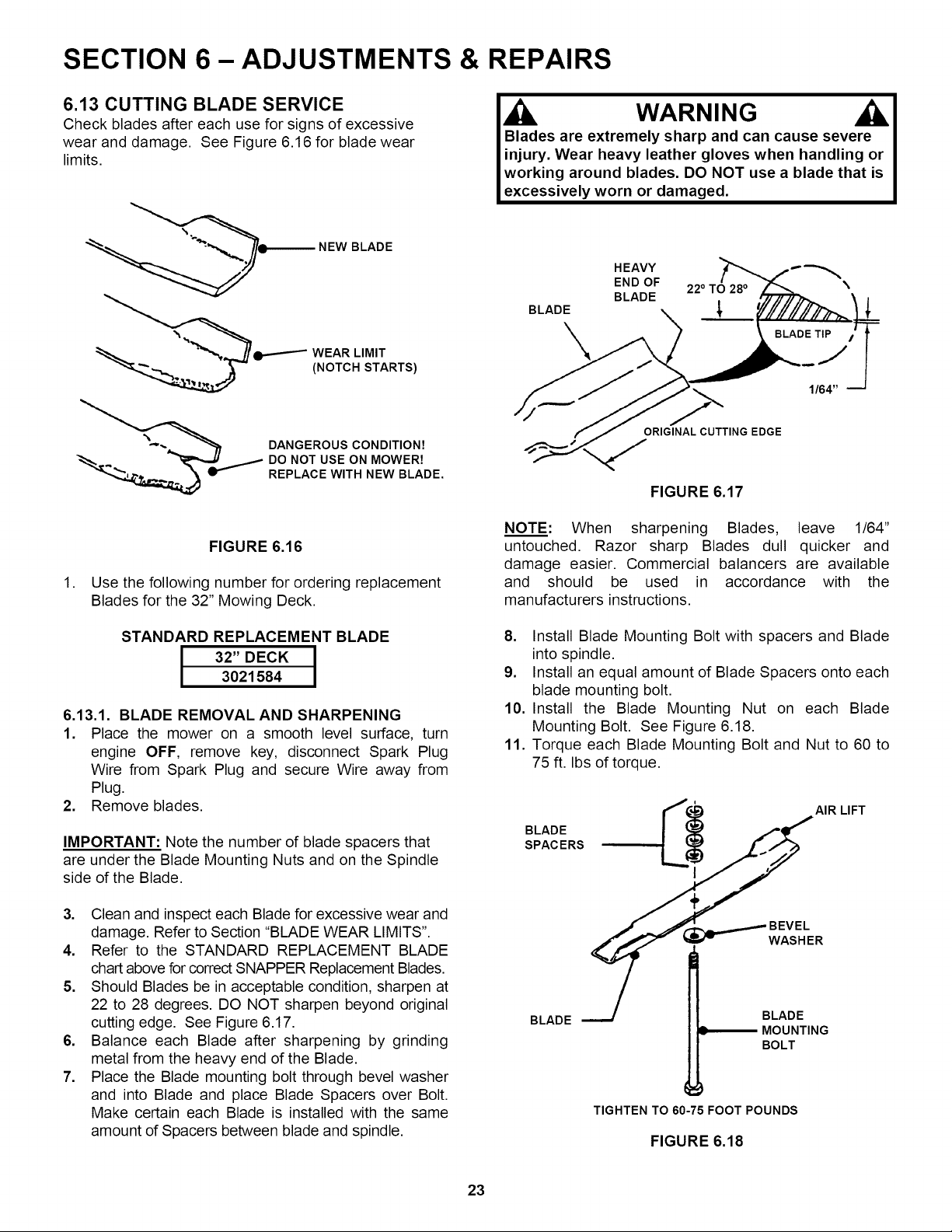

Check blades after each use for signs of excessive

wear and damage. See Figure 6.16 for blade wear

limits.

q_--------- NEW BLADE

WEAR LIMIT

(NOTCH STARTS)

DANGEROUS CONDITION7

DO NOT USE ON MOWER7

REPLACE WITH NEW BLADE.

FIGURE 6.16

1. Use the following number for ordering replacement

Blades for the 32" Mowing Deck.

STANDARD REPLACEMENT BLADE

I I

3021584

6.13.1. BLADE REMOVAL AND SHARPENING

1. Place the mower on a smooth level surface, turn

engine OFF, remove key, disconnect Spark Plug

Wire from Spark Plug and secure Wire away from

Plug.

2. Remove blades.

IMPORTANT: Note the number of blade spacers that

are under the Blade Mounting Nuts and on the Spindle

side of the Blade.

3. Clean and inspect each Blade for excessive wear and

damage. Refer to Section "BLADE WEAR LIMITS".

4. Refer to the STANDARD REPLACEMENT BLADE

chart above for correct SNAPPER Replacement Blades.

5. Should Blades be in acceptable condition, sharpen at

22 to 28 degrees. DO NOT sharpen beyond original

cutting edge. See Figure 6.17.

6. Balance each Blade after sharpening by grinding

metal from the heavy end of the Blade.

7. Place the Blade mounting bolt through bevel washer

and into Blade and place Blade Spacers over Bolt.

Make certain each Blade is installed with the same

amount of Spacers between blade and spindle.

,Ji WARNING

Blades are extremely sharp and can cause severe

injury. Wear heavy leather gloves when handling or

working around blades. DO NOT use a blade that is

excessively worn or damaged.

BLADE

HEAVY

END OF

BLADE

22 ° TO 28 °

\

ORIGINAL CUTTING EDGE

FIGURE 6.17

NOTE: When sharpening Blades, leave 1/64"

untouched. Razor sharp Blades dull quicker and

damage easier. Commercial balancers are available

and should be used in accordance with the

manufacturers instructions.

8. Install Blade Mounting Bolt with spacers and Blade

into spindle.

9. Install an equal amount of Blade Spacers onto each

blade mounting bolt.

10. Install the Blade Mounting Nut on each Blade

Mounting Bolt. See Figure 6.18.

11. Torque each Blade Mounting Bolt and Nut to 60 to

75 ft. Ibs of torque.

_"¢_'__ AIR LIFT

L$

I

÷

BEVEL

R

BLADE '-"-/ BLADE

MOUNTING

BOLT

TIGHTEN TO 60-75 FOOT POUNDS

FIGURE 6.18

23

Loading ...

Loading ...

Loading ...