Loading ...

Loading ...

Loading ...

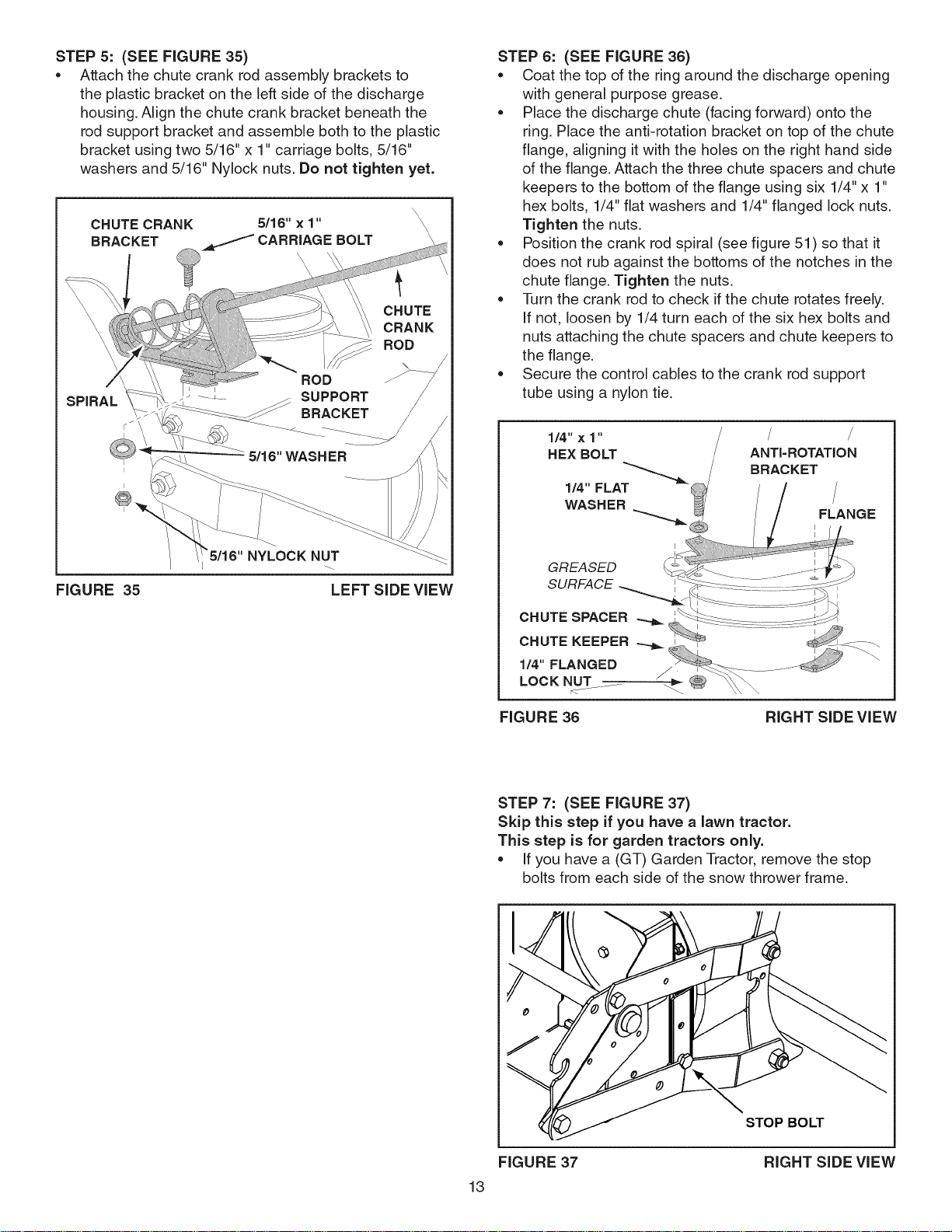

STEP5: (SEEFIGURE35)

Attachthechutecrankrodassemblybracketsto

theplasticbracketontheleftsideofthedischarge

housing.Alignthechutecrankbracketbeneaththe

rodsupportbracketandassemblebothtotheplastic

bracketusingtwo5/16"x1"carriagebolts,5/16"

washersand5/16"Nylocknuts.Donottightenyet.

\\

CHUTE CRANK 5/16" x 1" X

BRACKET CARRIAGE BOLT \

CHUTE

CRANK

ROD

SPIRAL

FIGURE 35 LEFT SiDE ViEW

STEP 6: (SEE FIGURE 36)

Coat the top of the ring around the discharge opening

with general purpose grease.

Place the discharge chute (facing forward) onto the

ring. Place the anti-rotation bracket on top of the chute

flange, aligning itwith the holes on the right hand side

of the flange. Attach the three chute spacers and chute

keepers to the bottom of the flange using six 1/4" x 1"

hex bolts, 1/4" fiat washers and 1/4" flanged lock nuts.

Tighten the nuts.

Position the crank rod spiral (see figure 51 ) so that it

does not rub against the bottoms of the notches in the

chute flange. Tighten the nuts.

Turn the crank rod to check ifthe chute rotates freely.

If not, loosen by 1/4 turn each of the six hex bolts and

nuts attaching the chute spacers and chute keepers to

the flange.

Secure the control cables to the crank rod support

tube using a nylon tie.

1/4";(1"

HEX BOLT ANTI=ROTATION

GREASED

SURFACE

CHUTE SPACER

CHUTE KEEPER

1/4" FLANGED

LOCK NUT

r<.............

FIGURE 36 RIGHT SiDE ViEW

STEP 7: (SEE FIGURE 37)

Skip this step if you have a lawn tractor.

This step is for garden tractors only.

If you have a (GT) Garden Tractor, remove the stop

bolts from each side of the snow thrower frame.

13

FIGURE 37

STOP BOLT

RIGHT SiDE ViEW

Loading ...

Loading ...

Loading ...